Starbank has just replaced Homag’s BAZ 723 with the very latest Centateq E-700

.

Exciting times once again at leading panel fabricator Starbank as they launch their latest CNC shaped edgebanding machinery, part of their wider £2m investment plan for 2023.

Established in 1976, employing a 90 strong team, Starbank have always enjoyed very strong inward investment from their shareholders and their latest CNC purchase is no exception.

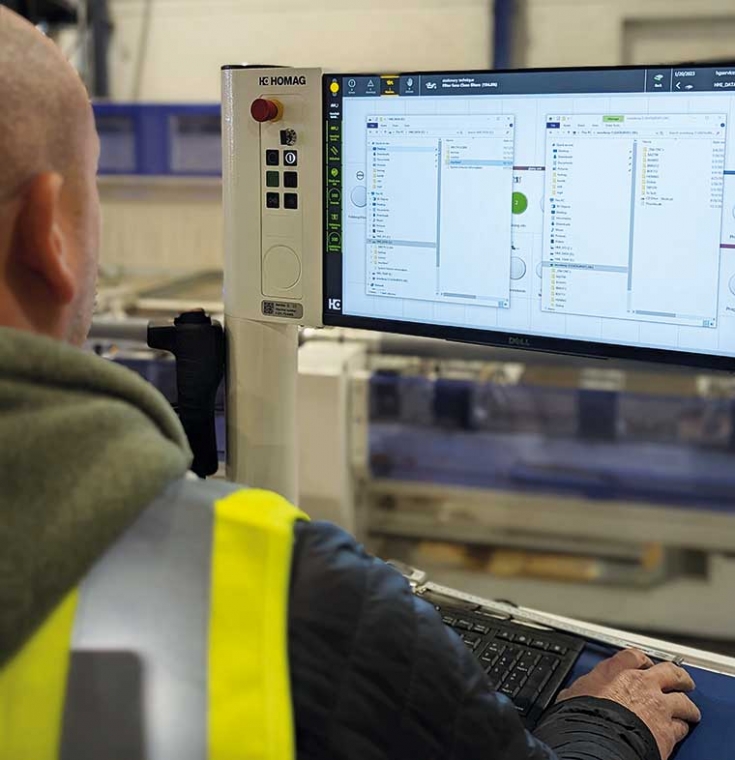

The company is replacing a Homag BAZ 723, installed in 2015, with the very latest Centateq E-700. Both machines are high-performance twin table, twin router gantry series CNC’s and the flagships within the Homag range. The 116,000 sq ft manufacturing facility currently houses 20 custom machines to handle laminate and panel fabrication from batch size 1 to batch size 10,000 and beyond.

Impressive software improvements

Philip Darbyshire, Managing Director explains: “We took the critical decision with our replacement Centateq E-700 to invest in unique technology and upgrades that were not possible previously. Whilst our skilled production team will take full advantage of these upgrades, the ultimate benefit of these investments is for our customers who can now request a completely seamless edge to their own shaped panel components.”

Whether Melamine or HPL in composition the benefits are not only for high-end surface finishes, which really do deserve the ultimate edge, but also for basic components in challenging environments that require higher levels of hygiene and ease of cleaning.

PowerEdge Pro Duo edgebanding unit

The new machining centre will not only run the very latest Airtec system, but also the powerEdge Pro Duo edgebanding unit. This upgrade takes CNC edge gluing to a whole new level with superior butt banding, trimming and software innovation providing higher accuracy and quality.

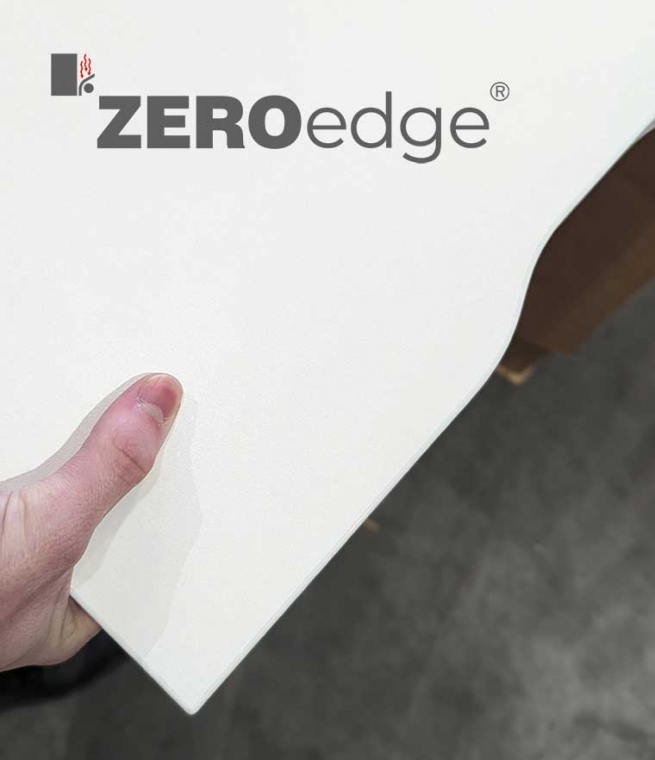

When using the ZEROedge® system this can create a bond equal to or greater than PUR (no delamination).

Starbank’s newly-launched ZERO-edge brand

The Airtec system uses highly compressed hot air that effectively welds the functional layer on the edgebanding directly to the board. This system does not require the use of a traditional adhesive layer between the board and the tape, drastically improving the visual appearance of the part with additional benefits in exceptional heat and water resistance. Effectively, there is no place for any dirt to accumulate over time and use.

This new technology will finally be complimented towards the end of Q1 when Starbank take delivery of their new Homag S-800 Edgebanding Cell which will run a Lasertec system for straight line edgebanding.

Butt banding improvements

Starbank explain they have been watching the market closely for many years with regards to the myriad of new surface and machinery technology available and are very excited and proud to launch their new ZEROedge® brand to the market: “There is absolutely no doubt that the market demand for higher quality components is a constant requirement, and we are addressing both current and future needs for many years to come with our latest investments. As an OEM manufacturer, we are upgrading a great number of parts and products for our customers which can only be a good thing,” concludes Philip.

To find out more about ZEROedge® get in touch with the Starbank team on 01925 223965 or email [email protected].