Richard Oxley, director of Becker UK, speaks on the many benefits of ensuring vacuum equipment is fit for purpose ...

Is your CNC machine playing up? Worried you’ll need to replace the whole thing? Tired of wasting wood due to repeated cutting issues? We’ve got good news. It might not be a fault with the machine itself. It’s unlikely it’s the materials you’re using. And there’s nothing wrong with your skills as a woodworker. The problem might be your vacuum.

A poor, weak, or inadequate vacuum can cause a whole host of problems that often get blamed on other things. So, if you’re experiencing any of these issues, then your vacuum pump should be the first thing you investigate:

Poor quality cuts – if your vacuum is weak, your boards can slip during cutting, resulting in poor quality, irregular or inaccurate cuts. This results in wastage, which could otherwise be avoided. Chipping of boards – if your vacuum isn’t holding your board in place with enough force, and the boards move or vibrate during machining, this can cause the board to chip. Again, this causes wastage that could otherwise be avoided. Damaged tooling – a poor vacuum can lead to increased vibration, which can cause damage to tooling. Not only does this mean extra cost in repairing or replacing parts, but it can also delay production or cause unplanned downtime.

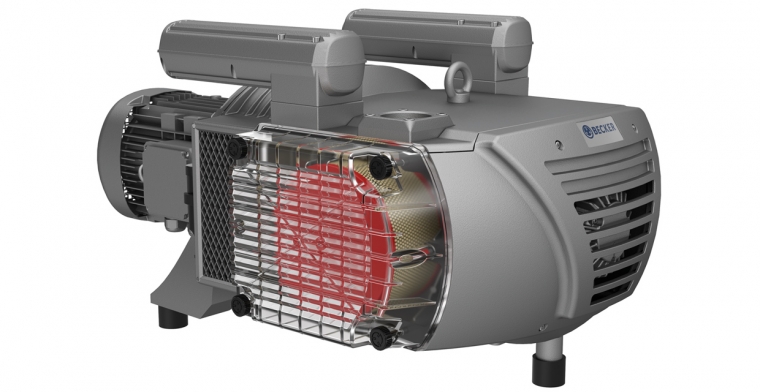

Pictured: BCV 300

The cost to your business

If you’re worried about the cost of replacing your vacuum, don’t be. While there might be an initial cost to investing in quality parts, the cost of not investing will be much higher.

In wastage – chipped boards and inaccurate cuts mean wasted materials. Even if you’re only experiencing problems every now and then, these will still add up, and the problem will only get worse.

In running and maintenance costs – damaged tooling means replacement parts, and replacement parts cost money. On top of this, an inefficient pump will be using way more energy than it should, adding to your energy bill (and your carbon footprint).

In downtime – If a vacuum pump is down, the machine cannot operate, resulting in unplanned downtime. This will impact the progress of any current jobs, costing you money, but also your reputation. Ignoring your pump problems is like throwing money away, so it pays to resolve the issue quickly

What’s causing the problem?

There are many variables that could be contributing to a poor vacuum, and it is sometimes difficult to identify the issue. But the good news is, if you can figure out the problem, you might not need a new pump at all.

Dust and debris – the issue could be as simple as a build-up of dust and debris. Make sure you clean your spoil boards, router tables and seals before the placement of new workpieces.

Incorrect set-up – the way your machine is set up could be causing the issue. For example, if gaskets aren’t cut and fitted correctly, the tolerance between ends might be too high, affecting your vacuum pressure.

Leak in the vacuum system – if you have a leak in your vacuum process, this will most certainly be causing problems with your vacuum pressure.

Lack of servicing – poor maintenance of the filter unit will increase the pressure loss over the filter, resulting in a reduced vacuum level. It could also lead to filters rupturing and damaging the pump.

Wrong type of pump or filter – for fine composite materials, some vacuum pumps need a filter with a lower micron rating. Without the correct filter, some particles may enter and potentially damage the pump’s internal mechanics.

Actions you can take

The first priority should be making sure your vacuum equipment is fit for purpose and as energy efficient as possible. Overkill vacuum solutions are commonly used and, although you may not notice any issues with performance, these solutions could be resulting in a lot of wasted energy.

To maximise energy efficiency, you can use a pump with a variable frequency drive. This can be an effective way of reducing energy costs by up to 25%.

Depending on the machinery and the required operations, your vacuum could be better utilised with a Rotary Claw pump rather than Vane. Becker Claw pumps have been designed for minimal noise emissions, keeping your production area quieter too.

Once you’ve got the right vacuum system in place, servicing and maintaining it is your next priority. Becker yearly services are carried out by expert engineers, and we only use genuine Becker parts. Our engineers are also available on a 24-hour call-out to keep your machines operating around the clock.

Becker VTLF Rotary Vane Vacuum Pump

Make it Becker

Becker has over 100 years of experience in the vacuum industry, and all our pumps meet rigorous standards. Our products are built for reliability and longevity, and we have pumps active today within the woodworking industry that have been running for over 20 years for our clients.

Every product we supply has been designed for performance and efficiency. Our VX series, for example, has been designed to increase vane life by up to 20,000 operating hours.

As well as standalone pumps, we can also design and implement central vacuum systems. Because all your pumps are in one central location away from the production area, you reduce noise and heat levels on the factory floor.

A centralised system is lower maintenance and easier to access, plus you minimise machine downtime as back up pumps will kick in should a primary pump fail.

Need help with your vacuum systems?

If you’re experiencing any of the issues outlined in this article or would like to find out how your woodworking operation could benefit from centralised vacuum systems, we’d love to help. Get in touch with one of our friendly experts who will be happy to talk you through the most suitable solutions.

Contact our team of experts on 01482 835280 or visit becker-international.com