18 months ago, international fixtures, fit-out and maintenance company, CAPS Group, acquired its first manufacturing facility in the UK. Already established in Poland, central Europe, Asia and America and boasting an impressive portfolio consisting of Harley Davidson, Sports Direct, Accor Hotels, Vue Cinema, Triumph and L’Occitane, the new Stockport-based facility needed to be equipped with a new edgebander that would be used as part of an exclusive bespoke manufacturing service. To do this, CAPS Group enlisted the expertise of reconditioned machinery supplier, Ferwood UK, to source the right machine quickly and efficiently.

“In the past, I was always hesitant to buy used machinery,” begins Paul Wilson, CAPS Group’s operations director and UK managing director.

Paul Wilson, CAPS Group’s operations director and UK managing director

“As a global business, we aim to make the right decisions at the right time. We don’t solely focus on cost because we can never be seen to be short sighted. Before we came across Ferwood, we were under the illusion that second hand machinery was a false economy. Yes, we could save thousands on the purchase price but would the machine meet our high standards and would it last?”

It was Ferwood UK’s business model and unique 10-step reconditioning process that first grabbed Paul’s attention during an impromptu Google search. “I’d never come across a company that supplied second hand machinery in the way that Ferwood did and I was keen to find out more. Before embarking on a factory visit to see the processes for myself, I wanted to hear what Ferwood’s customers had to say about them and their machines. I was pleasantly surprised to read references from well known names in the industry.

“Many were big manufacturers who, I know from experience, would not only have the financial freedom to buy new if they saw fit, but would also need to drive their machinery considerably harder than we would as a niche manufacturer. If Ferwood’s reconditioned machinery worked for them, were we missing a trick?”

A trip to Ferwood Group’s 18,600 square metre showroom in Pollenzo, Italy, put an end to Paul’s concerns and opened his eyes to Ferwood’s flexible approach to used machinery sales. “The whole process was astonishing,” explains Paul. “I was taken through the entire process – from stripping the machine down to its carcass and rebuilding it with new parts to thoroughly cleaning and painting the shell. The production line looked like it belonged to a new machinery factory, not a second hand one. They were unbelievably thorough in terms of overhauling the machines and I could immediately see the possibilities open to us. Knowing each machine – regardless of the make or model – would come with a warranty made me change my mind set. A used edgebander from Ferwood was a good fit for our business.”

When deciding on the right machine for them, CAPS Group homed in on Ferwood UK’s considerable experience in the sector. “We knew that we wanted a premium machinery brand that would offer reliability and longevity but we were keen to get advice from Ferwood on the best make and model for our business,” explains Paul.

As Ferwood UK works with a wide range of machinery brands around the world, offering their customers unparalleled choice from the market. “In order to give the best possible advice, Ferwood was keen to find out more about our company and what we did, the processes we already had in place and the volume of product we were producing.

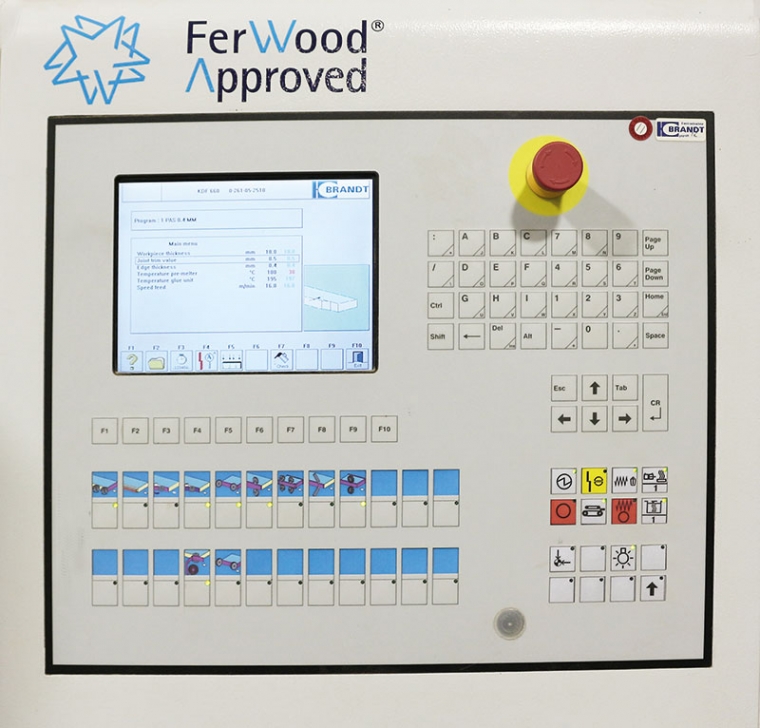

“They offered us several options that suited our needs and budget. The Homag Brandt KDF 660 Profiline edgebander was a good fit for us and ticked every box. In fact, it came with more extras than we originally discussed, helping us to future-proof our business.”

Once the sale had been agreed, the machine was fully refurbished in accordance with Ferwood UK’s Ferwood Approved brand package and installed into CAPS Group’s UK factory within six weeks. “They certainly didn’t disappoint with their lead time,” says Paul.

“We try and plan everything to the best of our ability. Whether it’s a new sales plan or assets acquisition strategy, our next move is always governed by our next order. Having the right machine in place at the agreed time and in full working order is key for the business to keep pushing ahead. And, if any issues do arise, we have seen first hand the amount of spare parts readily available to us if ever we need them.”

Paul concludes: “First impressions have always been important to me. You can have the best product in the world but if the person your talking to doesn’t have the right approach, or their knowledge falls short, it can de-value the brand. We had every confidence in Ferwood from the off. Their knowledge and background in the industry is second to none.

“That’s why we’re continuing to work with Ferwood on our next venture. We’re about to start building a new logistics centre next to our Polish factory and Ferwood was our first point of call for advice on how to grow our production facilities going forward.

“We embarked on this new relationship with our eyes wide open and as a result, we know that we can rely on Ferwood to provide us with good quality machines from premium brands, offer solid after sales support and allow us to benefit from their years of experience in the industry and vast manufacturing knowledge. I couldn’t recommend them more highly.”

0113 286 6689

www.ferwoodgroup.com