A key focus for Homag over the last few years has been based on the development of an innovative range of tools designed to simplify the daily workings for machine operators, whilst supporting production processes. While intelligent working has been at the forefront of developments within the woodworking industry, Homag has remained sensitive to ensuring its solutions are accessible for all levels of manufacturing.

Simon Brooks, managing director at Homag UK explains: “One of Homag’s core focuses has been on developing a set of intuitive tools that simplify the daily working life of machine operators. The new range of digital assistants demonstrate Homag’s commitment to providing the market with innovative, practical solutions to both simplify yet revolutionise production for the future.”

Homag’s range of digital assistants begins at the most important stage of production – planning, design and order management. Homag’s cabinetCreator is a web-based application which enables users to quickly and easily configure 2D/3D furniture visualisations.

Via an easy step-by-step process, operators can choose from a library of pre-defined basic furniture shapes, which intuitively adapt to specific inputted parameters or alternatively create their own library of designs. Aiding the fast generation of production data, the application also provides individual part drawings and 3D assembly diagrams.

Supporting with both planning and designing stages, cabinetCreator can be accessed easily on any internet device such as computers, smartphones or tablets – meaning operators can have an overview of the job status in the office, at the machine or on the go.

Once the design has been finalised, cabinetCreator produces a bill of materials required for cutting, whilst generating CNC programs which can then be exported for use. This design software offers a fast yet simple solution for turning customer requests into finished furniture pieces.

To efficiently collate all the order data related to each job, such as information from cabinetCreator, Homag has created a digital assistant called productionManager.

When it comes to order management, traditional handwritten lists are still commonly used throughout businesses, proving not only to be time consuming but a method that poses the potential threat of inaccuracy. productionManager however, simplifies the transition from paper to a more efficient and secure order system.

Flexibly importing data in different formats from different systems, productionManager summarises all production-related data, providing users with a transparent status overview of all orders. This app also enables users to effortlessly import the files to a digital job folder which can be accessed easily at any given time via smartphone or tablet.

At the same time, productionManager corresponds with further digital assistants which have been specifically designed for the latter stages of manufacturing. This includes applications such as productionAssist Cutting, otherwise known as intelliDivide, a cutting optimisation software which offers real time updates on production times, material usage and machinery status.

Encompassing key elements of the manufacturing process, Homag’s range of web-based digital assistants will transform business processes, helping manufacturers speed up production, improve efficiencies and reduce costs.

Homag’s productionAssist – helps users quickly identify and find workpieces

productionAssist: Sorting – eliminating the time-consuming search for components, this digital assistant simplifies the sorting process. Organising production to a high degree of accuracy, data collated from individually barcoded workpieces helps users to quickly identify parts correctly via the app.

Users are also able to visibly distinguish missing parts or confirm the completeness of orders, thanks to the intelligent part recognition on the sorting shelf via LED signals.

productionAssist: Assembly – illustrating both complete and exploded part drawings, as well as a 3D view feature, this digital assistant is specifically designed to aid the assembly process. Providing all information concerning a specific job straight to the user’s fingertips, productionAssist Assembly delivers detailed lists of all required fixtures, a bill of required materials as well as list of required hardware.

Within the application users can also display all of the furniture designs which can be assembled with the selected parts.

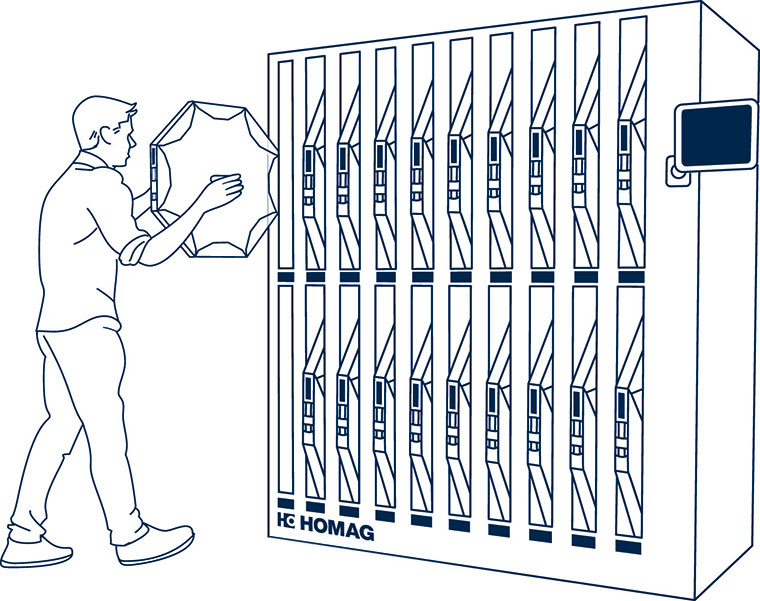

productionAssist: Edge – edgeband inventories can easily become disorganised if not managed carefully, however with Homag’s productionAssist Edge application, these can be handled in a simple yet efficient system.

Using the internet device of your choice, the management software in combination with intelligent edgeband shelving offers users direct access to stock and availability. Thanks to the clearly arranged LED display on the shelf, operators can quickly identify the edgeband they need eliminating any unwanted unwinding and damage.

Simon Brooks concludes:

“Revolutionising the industry with digital solutions, these new technologies from Homag enable us to assist manufacturers with all aspects of enhancing their facility to future-proof production processes.

“Increasing production efficiencies, reducing downtime and eliminating errors, these tools which are now available to the market bring a large range of production benefits to all manufacturers regardless of size.”

For more information on Homag’s latest digital assistants or any of the smart production products, call Adele Hunt on 01332 856424.