Since 1962, when Homag introduced the world’s first edge banding machine based on the hot-cold process, the advances made in technology and production have been incredible. These developments have resulted in extremely high demands from customers who now expect to get invisible joint quality edging on all their furniture.

Simon Brooks, managing director at Homag UK explains: “For over 55 years the Homag Group has been at the forefront of edge bander product development. During that time, it has launched many ‘firsts’ into the market including laserTec and more recently airTec. Now, we can offer invisible joint technology for any size of manufacturing business, from entry level through to high volume industrial production.”

airTec - invisible joint edge banding solutions from Homag

The airTec system

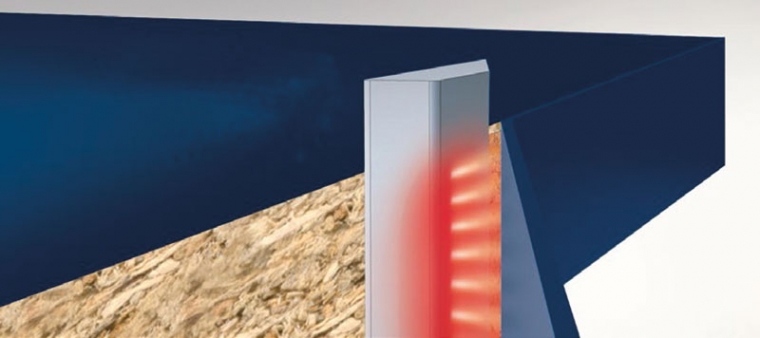

Following on from the success of laserTec (first seen in 2009), Homag introduced the airTec technology in 2015. The airTec system uses hot air and special edge material to form an invisible or zero-joint. The special edge material consists of a hard décor layer backed with a meltable functional layer. This functional layer is melted by the hot air and then pressed onto the panel edge.

The airTec process is very clean and cost-effective and results in perfectly crafted products, where joints are no longer visible. The airTec system is available across Homag’s full range of edge banders allowing even the smaller business to compete in the invisible joint market where frontals, such as doors and drawers, need to be of a very high standard.

The Homag Edgeteq S-300 – high performance airTec solution for entry level workshops

Entry level airTec solutions

The Homag Edgeteq S-240/300 models are robust entry level edge banders that offer a high performance solution for bespoke workshops. These compact, affordable models provide a high degree of automation with minimal footprint.

They handle workpieces up to 60mm thick and can bond coil edge tapes up to 3mm thick or 8mm in strips. All the models use the intuitive powerTouch control system and offer highly flexible configurations to enable the tailoring of the machines to exact requirements.

The Edgeteq S-240/300 models come equipped with a pre-milling unit for optimum edge joint quality, Homag’s in-house manufactured airTec system, end snipping saws front and rear, a trimming unit with DFC tool technology for maximum dust extraction, a contour trimming unit for optimum corner rounding as well as scraping and buffering units for the perfect finish. The machines are also supplied with a conventional glue pot making them great all-rounders.

Mid-sized airTec solutions

For higher outputs, the Edgeteq S-380/390 models from Homag provide versatile, high quality edge banding on a consistent basis. They offer both airTec and Quickmelt gluing options for easy changing of the colour and glue type (EVA, PU).

In standard trim, they offer a variable feed speed from 8-18m/min, with an option to increase feed rates up to 20m/min. As well as a heavy duty pre-milling unit for panels up to 60mm in thickness, the Edgeteq S-380/390 models boast a two-motor end-snipping unit, top and bottom trimming units, a servo-controlled corner rounding unit, with automatically selectable profile and surface scraping units for the perfect finish.

For the mid-sized manufacturer with growth ambitions, the Edgeteq S-380/390 provide the ideal platform to help drive business to the next level. These high-performance units offer precise gluing and perfect post-processing of edges even at high feed speeds. With a wide range of equipment options, including highly flexible corner processing, these machines can be fully automated for short set-up times and maximum operator convenience.

Homag Edgeteq S-380/390/500 profiLine

The development of the Homag profiLine series has provided an innovative answer to growing competitive pressure in the furniture marketplace. Manufacturers in this field are confronted with ever-increasing material diversity. As a consequence, any edge banding machine must be both efficient and capable of material-independent application.

The Edgeteq S-380/390/500 profiLine machines are capable of processing any kind of edging material customarily used by the processing industry today. These include for instance, solid wood, coil and strip material, melamine, PVC, ABS, aluminium, acrylic and veneer edges.

In terms of both performance and tool arrangements, all models are freely configurable. These single-sided edge banding machines offer feed speeds of 20, 25 and 30m/min and can be used with or without a joint trimming unit. The extensive range of modules, meanwhile, makes tailoring the machines for specific requirements easy.

For automation, the Loopteq return systems provide the ideal complement to the Edgeteq S-380/390/500 profiLine machines, increasing productivity, eliminating damage from handling errors and allowing time for quality control.

Homag Edgeteq S-500 – high feed speeds with guaranteed precise workpiece guidanceairTec – invisible joint edge banding solutions from Homag

Industrial airTec solutions

The Homag Edgeteq S-500 series edge banders offer comprehensive equipment as standard, providing higher performance with and without empty slots.

The feed speeds range from

16-30m/min and all the models deliver a high level of flexibility processing high-gloss, melamine, PVC, nesting workpieces with, for example, hinge holes, solid strips and, in the case of some models, veneer edges.

With a steel belt-type top pressure unit, the Edgeteq S-500 series edge banders guarantee precise workpiece guidance at high feed speeds.

Automation and further functionality can be added on an individual basis for these machines. As with the ProfiLine series, Loopteq return equipment provides a productivity boost by making it easy for a single operator to run the machine.

Homag airTec – a solution for every need

Simon Brooks again, “Specifying the right edge bander for your business can be daunting at first. That’s why we encourage all our customers to visit our showroom in Castle Donington.

“Not only does it give them the chance to see the machines in action, but they also get the opportunity to pick the brains of our talented team who have access to the immense knowledge and experience bank that the Homag Group has amassed over nearly 60 years of edge banding production.

“The breadth of solutions we offer for the small right up to the industrial-sized manufacturers, is comprehensive to say the least. And of course, with Homag, you are investing in market-leading German engineering blended with cutting-edge technology and performance.”

Homag Finance – making your investment viable

“We recognise that cash flow is the lifeblood of any business, from the small workshop to the mass production manufacturers. Having access to the right finance is, therefore, essential and the Homag Finance team is here to negotiate the right deal for you; a deal that meets your financial capabilities without putting undue strain on your cash flow.

“The demand for high quality products with invisible joints in a wide range of edging tapes and colours is not going to go away. Our team of experts here at Homag would love to help you specify the right solution, at the right investment level for your business. If you would like to see a demonstration of any of the Homag Edgeteq edge banding solutions, call Adele Hunt at Homag UK on 01332 856424,” concludes Simon.