Jonathan Rose Fine Furniture was founded in 1997 to provide a professional furniture making and engineering service to designers and private clients.

The firm’s determination to maintain quality craftsmanship has never wavered and its highly skilled team of craftsmen is dedicated to the efficient manufacture of individual pieces of furniture.

The Klever 1530 G flat table CNC machining centre

So that it could provide the accuracy and repeatability required for its high-end furniture production, the company needed the facility of a multi-faceted CNC machine – but the company had no CNC capabilities prior to purchasing Biesse machines: a Klever 1530 G FT flat table CNC machining centre and Rover A 1632 five-axis CNC machining centre.

“We decided to purchase two machines as they provide diverse capabilities,” explains founder Jonathan. “The Klever flat table machine produces items more quickly and with better accuracy. The value for money this machine provides made our decision very easy.”

The investment in a new manufacturing facility is indeed impressive, with a new air-conditioned CNC workshop, which houses both machines and provides an excellent working environment for operators Tom and Sarah.

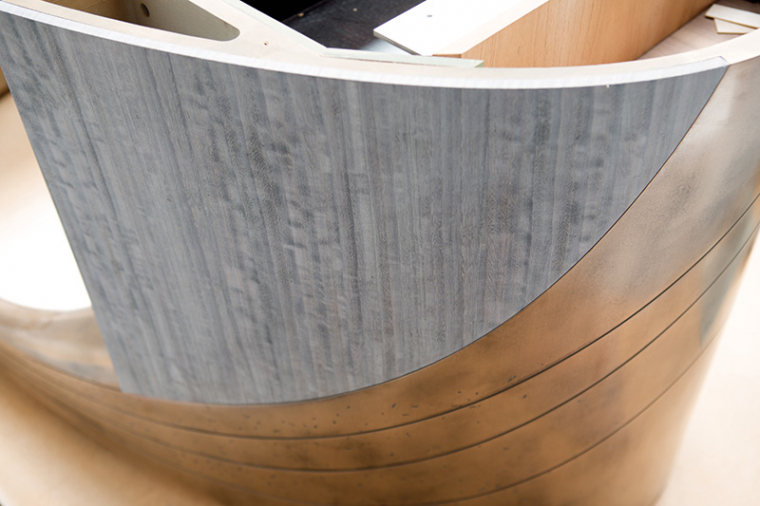

“The Rover A five axis is a game-changer in terms of capability,” Jonathan enthuses. “It has enabled us to win more business as we can now manufacture furniture we weren’t able to before.”

Jonathan Rose is very innovative when it comes to translating the designs of its customers into tangible objects and its use of Biesse’s software, bSolid, together with the Rover A’s capabilities and operator skills, produces striking pieces of furniture which previously, could only be hand carved.

“The machines have enabled us to produce more intricate and complex designs but one of the other exciting benefits is the human factor – there is greater opportunity for our workforce with a tremendous feeling of progression,” says Jonathan.

“Biesse’s Total Care five year warranty and service plan was a massive contributing factor in our decision-making process. It’s a one-stop-shop as far as we were concerned. Biesse go the whole nine yards and take responsibility for the complete delivery and installation service. Once we’d placed the order the rest was easy. Biesse conducted a site survey, offloaded, sited, installed and commissioned the machines.”