Established in 1989, the AES Group has evolved to become a global supplier of one of the most comprehensive ranges of heavy duty, high quality industrial CNC machines.

The strengths of the AES CNC machines can be quite clearly seen in the construction of the frames, which allow every machine to have a high positioning and processing speed to allow maximum productivity. These machines generally weigh more than most to easily absorb positioning speeds which start at 70m/min and are built to ensure long term reliability and accuracy.

“If you were to strip down an AES machine, you would see that only the frame and assembly takes place in their manufacturing plant of over 170,000 sq ft in Bursa, Turkey,” explains J & C O’Meara MD Carol O’Meara, “and all the working parts are from the world’s highest quality – branded sources including Becker Vacuum pumps, HSD router and drill heads, Yasakawa inverter drives, THK linear guides, Schmaltz vacuum pod and consoles, Osai controllers etc.

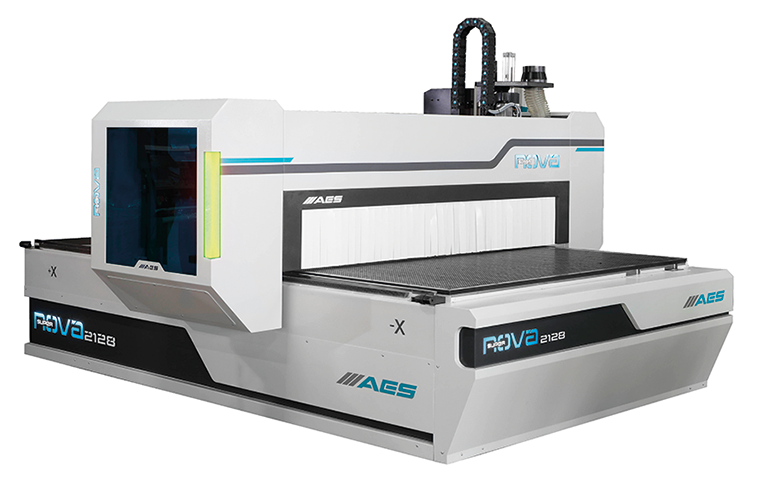

Super Nova

Quality process

Every one of the 300 machines produced every year goes through a number of stringent and rigorous quality checks and procedures to ensure every machine meets or exceeds customer expectation.

“Every AES machine comes complete with industry leading Alphacam CAD/CAM software, starting with Essential 2D which can be upgraded to further packages depending upon customer requirements and of course allowing every customer the possibility to ‘grow’ with the machine,” explains Carl.

Door production

With a choice of three axis and five axis machines, AES has several solutions depending upon customer requirements. One of the most popular choices is the AES Vega Evo which has a 9Kw router head and double sided 5.5Kw dedicated horizontal router head to machine pockets for locks and recesses for hinges.

The easy-to-use AES door macro allows one-off programming in minutes, which include final sizing of the door blank, machining of locks, hinges, keyway, handle hole, rebates and eurogrooves. Spy holes and cut outs for letterbox and vision panels can also be added with ease.

Panel processing

From the entry level Flexa/Flexa Pro to the stand alone Super Nova to the heavy duty Extreme and Raptor Ultra machines – which can be supplied as automated line machines – AES has possibly one of the largest series of flatbed/nesting machines available.

As manufacturers’ requirements – and indeed budgets – are different, AES has a range of machines to suit most industrial requirements with each series of machine having the choice of several bed sizes depending upon maximum size sheet to be cut.

Drilling

The AES Sirius is a throughfeed drilling machine, again offering the traditional heavy-duty rugged structure and using all quality, branded components. This machine has the option of a router and also the option of a six-position toolchanger, giving it large machine capabilities in a smaller space.

The Vega is the stand-alone solution for modular furniture or processing door blanks and is available with a dedicated horizontal router head and C axis.

Vega 5X

Five axis

The five axis machines are becoming more and more the norm. The AES Vega five axis machine has a gantry construction to ensure ultimate stability when machining all round and is complete with a liquid cooled 11Kw HSD infinity head which can offer 360° endless machining to give a seamless finish.

This machine is also complete with the powerful Alphacam Ultimate CAD/CAM software.

Training

One of the country’s leading woodworking machinery dealers, J & C O’Meara is well placed to offer advice on the best software solution to allow CNC machines to be integrated into any existing working environment, whether a customer is new to CNC or even if a third-party CAD/CAM package is already being used. J & C O’Meara’s experienced team is also available to offer practical advice on machining styles, strategies and automation.

“Our training is not only about showing the function of the software but taking a customer from design through to production and includes pre-delivery training, training on site, along with on-going training,” concludes Carl.

01704 893 109

www.ukwoodworkingmachinery.co.uk