Truwood Furniture was founded in 1984 by Gordon Cook. In 1993 it moved to its current site and after humble beginnings is now supplying both traditional and contemporary rural designs to independent retailers and distributors, as well as direct to the trade.

The Flintshire company based in Mold, North Wales, has been using the Hoffmann system for some 20yrs now. MD Gordon Cook is such an enthusiastic devotee that he originally helped Hoffmann UK MD, John Galvin, develop and fine tune the system. That system originally incorporated the Morsø guillotine alongside the Hoffmann MU2 to manufacture the perfect Face Frame joint every time.

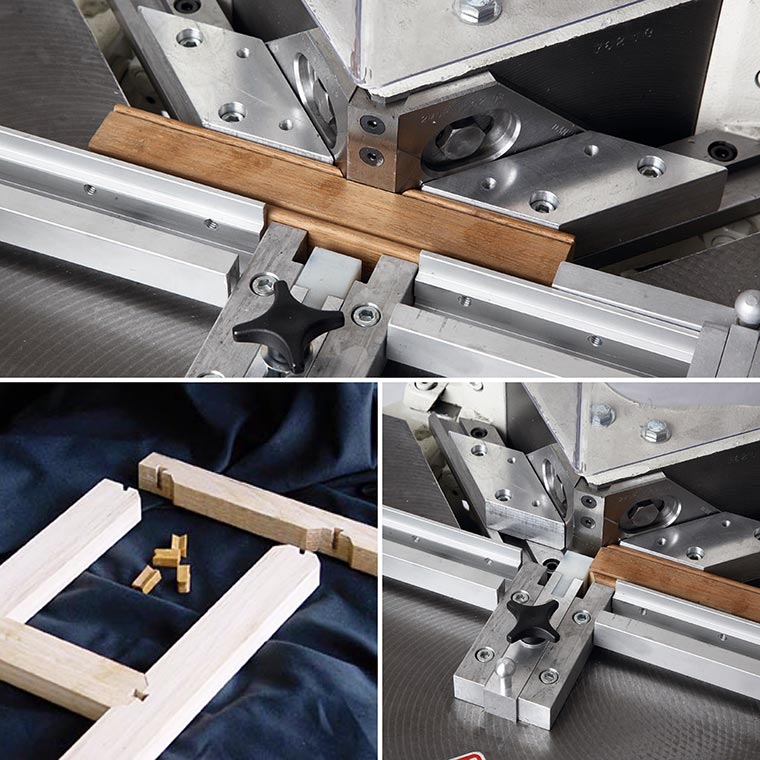

Because all products end up being fully bespoke, the speed and accuracy of the Hoffmann system has been crucial to Truwood’s success. At the workshops in Mold, they operate two Morsø guillotines and still use the original Hoffmann MU2 router (now superseded by the greatly improved MU3).

The latest Guillotine is fitted with the Glide stop positioning system on the fence which gives Truwood instant and accurate set-up times for different components. “It’s a superb system” says Gordon “which saves us significant time, is easy to use and 100% accurate every time.

The guillotines will cut out joints, including haunch joints, in hardwood components that have been pre-moulded to include an integral cock bead. The perimeter and internal cross section of the face frame fit together perfectly and once the Hoffmann key has been inserted into the routed keyway slot the frame will have permanent and accurate structural strength and accept the cabinet door or drawer front as a perfect fit”.

“By employing the Hoffmann system rather than using traditional jointing methods we can save up to 70% of time, eliminate any bad fitting joints and rejects and save all the time, space and cost of having to glue and clamp with the associated curing times. The system is incredibly user friendly and any one in the workshop can learn to use it in a very short time.”

The Hoffmann system is used worldwide in the construction of every type of joint in furniture making, joinery – kitchens, door frames and staircases – construction, framing and many others. After almost a quarter of a century in service, the MU2 was upgraded to suit todays and tomorrow’s industrial needs. – enter the new MU-3.

This thoroughly revised machine has been reworked, updated and adapted to suit the current and future needs of the industry, with many new additional features and is available in four versions:

MU-3 Basic version for the quick and precise routing of dovetail slots MU-3 D Digital version, with electronic two-axis display for the adjustable routing depth as well as the positioning of the centre fence for the routed slot location. It is ideal for high precision work. MU-3 P Pneumatic version for series production and high throughput. Pneumatic workpiece clamping and controlled router feed. The MU-3 P is operated by foot-pedal control. MU-3 PD Pneumatic/Digital version – the top machine with the highest operating comfort for a wide range of requirements. Functional features are similar to MU-3 P with a digital two-axis display for the adjustable routing depth as well as the positioning of the centre fence for the routed slot location.The MU-3 and the MU-3 D have a workpiece thickness capacity of up to 140mm – in the versions MU-3 P and MU-3 PD this increases to 170mm. Infinitely adjustable routing depths up to 95mm and protection against break-through of the finished surface. Also new is the two-function hand lever for even faster machine cycles when routing smaller workpieces. The scale tapes in the table and now also in the rear fences assist the quick and precise positioning of the workpieces. All versions of the new MU-3 routing machine are equipped with a motor carriage which has vernier adjustment for the fine setting of the router cutter and hence the tension of the joint.

All of the machines and the full range of products and methods are detailed on the Hoffmann website.

01524 841500