SCM presents Blade Off, the predictive safety system for circular saws recognised with an award at Xylexpo in October and the new compact three-axis Startech CN K machining centre.

Absolute safety and programming simplicity as well as control for artisan workers with less experience using tool machines, as well as the chance to benefit from all the digital advantages – the latest products from SCM in joinery which made their debut at the Xlyexpo 2022, meet all these important objectives.

Blade Off

In Milan at Xylexpo, Blade Off, the exclusive technological solution applied to SCM circular saws, won the XIA Xylexpo Innovation Award in the ‘panel machining’ category.

Blade Off is a predictive system of direct detection that eliminates any kind of accidental contact between the operator’s hand and the blade. This is thanks to smart sensors that can identify and recognise the human body from materials that can come into contact with the blade. The system triggers even before the blade is accidentally touched or the operator gets too close, by activating a barrier that protects the whole danger area around the blade.

Should a possible collision situation arise, the system automatically excludes the blade and stops the program running, without damaging any part of the machine.

A further bonus, that makes this system even safer, is that the detection is not based on re-elaborations/predictions made by algorithms, nor optical detections that could be read as calculation errors or poor visibility of the video camera.

Furthermore, the protection is enhanced on three sides of the machine (piece entrance and side approaches to the blade) to prevent any kind of contact, even caused by inappropriate or accidental movements.

The system also activates with high cutting speed, without slowing down machining, and includes the possibility of an unlimited reactivation, that does not influence the cutting precision nor the machine’s performance.

Another important advantage is the possibility of viewing and monitoring the operating status of the machine thanks to a useful LED light positioned on the blade’s protection.

Startech CN K

The Startech CN K is a compact three-axis machining centre which also made its debut at Xylepxo. It was developed for any kind of routing, decorations, scoring, production of signs and 3D model prototype.

The CN K also provides machining in absolute safety: its integral cabin, with internal LED lighting, guarantees the operator’s safety and keeps the surrounding area clean, as well as dramatically reducing the noise produced by machining.

The three-axis machining centre is unique in its kind with its 2.4kW electro-spindle with R25 attachment generally used on more powerful machines.

Another significant advantage is its easy programming thanks to the ‘open’ virtual human-machine interface to import G-code from any kind of CAD/CAM software.

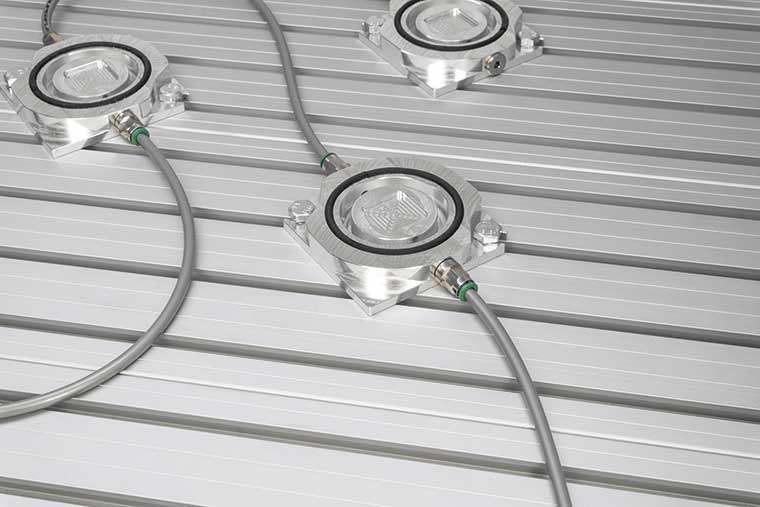

Furthermore, optional extras have been devised specifically to ensure no limits are imposed on the user’s creativity: the interpolating fourth axis (turning) that can be positioned on the worktable, the pneumatic suction cup kit to attach the piece (again on the worktable), and the detection sensor at tool height to guarantee maximum reliability.

Startech CN Plus

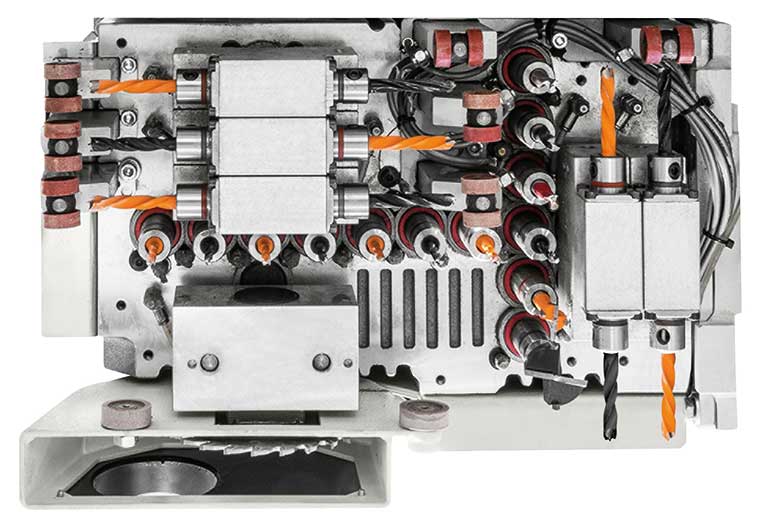

Startech CN Plus is the CNC drilling centre designed for SMEs as well as large joinery workshops that produce off-line or host prototyping departments. Indeed, the machine has eight separate vertical spindles, six horizontal spindles, the blade in X and a version with milling unit.

One significant advantage is its excellent flexibility: furniture parts can easily be created without having to reposition the tools and without intervention from the operator to set up the worktable and machine when the panel sizes change.

Set-up and implementation times are reduced to a minimum thanks to a speed of 40m/min.

Excellent advantages in small spaces: Startech CN Plus takes up just 5 sq m in space. At Xylexpo, SCM’s CNC drilling centre was one of the leading solutions for the Smart&Human Factory for the artisan worker: an integrated cell for flexible and customised production from the raw material to the finished piece of furniture, including the Invincibile SI Xcircular saw and the ME 40TR edgebander – three machines for an orchestrated work that dramatically reduces times and margins of error.