Based in Chorley, Lancashire, Screentek is a successful British designer and manufacturer of high quality furniture for offices and corporate spaces. With high expectations from their customers, Screentek’s manufacturing capability likewise needs to be on point.

With Screentek having many CNC machining centres from different manufactures, it was time to look at upgrading some of the older machines with newer, faster machining capabilities and to increase production with a flexible machine and software system.

Screentek’s Head of Operations, Martyn McKendrick, began to research numerous CNC router supplier options, one of which was VWM Woodworking Machines based in Trawden near Colne in Lancashire. He reached out to Managing Director Jason Varey and had an initial discussion. After checking out numerous other potential suppliers, Martyn opted to work with VWM.

A small sample of Screentek's output

“Screentek decided to source their CNC router solution from us not only because of the inherent high quality and very competitive pricing of our machines, but also our strong service-oriented ethos,” explains Jason. “Our superior site back-up often wins us work and it turned out to be a key issue here, that and our broad product range of machines VWM offers stands us in good stead with our customers.”

Jason also points out that Screentek opted to go with them because of the breadth of machines and industry expertise that they provide. VWM offers machines and equipment from the likes of Robland, Lange, Salvamac, Casolin, Steton, Falachi, Inventair, Purtsch and others.

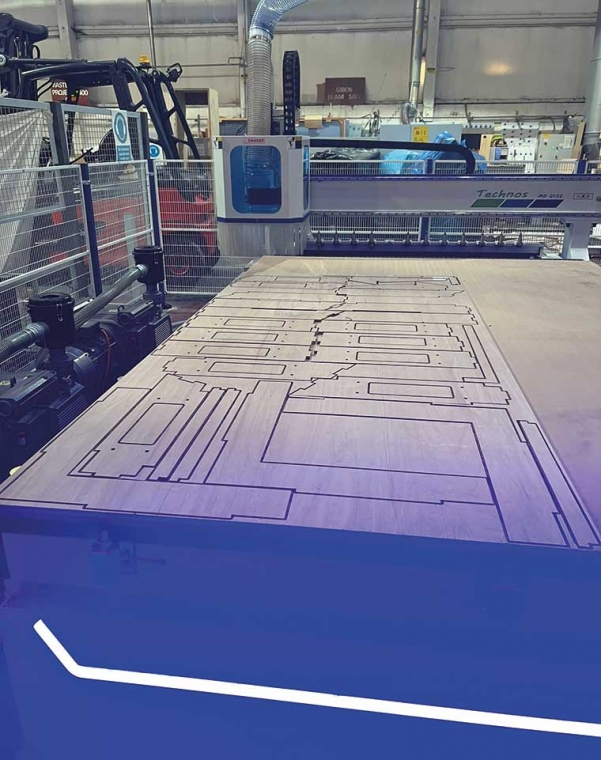

Screentek decided on the highly capable Technos 2132 MD CNC router – a set-up which is ideally suited to nesting production. “The 2100mm x 3200mm table machine (Y and X axes) is our largest table size in the MD range featuring a 250mm working depth on the Z axis,” explains Jason.

“Complimenting the wide range of machining available on this machine is a 12-position tool rack sited at the rear of the machine. This allows it to perform automatic tool changes throughout the program giving a wider range of tooling options when machining – and to speed up production time.

“Additionally, there is a fixed tool probe at the rear of the machine to guarantee accuracy between the tools on depth of cut as there is no manual setting needed. The machine also has automatic stops around two faces of the bed to locate boards correctly every time.

“The 9kw router head is capable of delivering all of Screentek’s machining needs with an inverter driven at varying spindle speeds up to 24,000rpm. All axes are designed with servo motors on precision helical racks. The servo motors are controlled from Premium Innovance Servo drives to ensure accuracy every time with rapid axes speeds of 50m/min. This is accompanied by two EuroVac 250m3 vacuum pumps and the manually-operated eight-zone matrix bed to ensure all parts are held securely during operation. The brains of this machine is the Syntec 60CA controller which has a very user-friendly operating system.”

In terms of what the new machine has meant to Screentek, Jason says: “It has improved their performance as our software is much more user-friendly and has far more features than before. Also the Technos machine is a more accessible machine which also benefits from quicker feed rates and a far superior vacuum system enabling the customer to successfully complete nesting production.”

The machine is fitted with reduction boxes to the X and Y axes for greater power, light beans to the loading area, a machine guard rail to three sides and full CE regulation.

How has VWM navigated the challenging last two years, what does the future look like? “The past two years have been an excellent trading period for us,” says Jason, “we anticipated that from July onwards in 2021, it would be a very quiet period and this would continue through to June 2022, but this did not happen. Looking forward, we have two full joinery shop fit-outs scheduled in January and five CNC machines to install as well.

“Looking back, Covid was a fantastic trading period for us. We did struggle a little with certain supply chains, but on the whole, it was a fantastic growth period – in 2019 we supplied 19 CNC machines and that rose to 23 on 2020 and this number continues to grow. Couple this with our other product lines we have seen a very sharp up turn,” says Jason.

“For some time our most attractive product line has been our impressive Technos range of CNC routers – if you consider you can have a machine delivered and installed in a week period from as little as £23,950 it represents amazing value for money. We then offer a range of machines all the way up to high production units which can run shift patterns in the most demanding production environment.

“So a customer can feel totally comfortable in investing in one of our machines as they can grow with us without the need to source from somewhere else and that makes life a lot simpler for our customers – we offer very competitive prices, good quality machines and outstanding service backup all from under one roof.”

Although confident Jason is aware that the current economic situation will have an effect. “We can see a small downturn coming but we think it’s more a seasonal one rather than a recession – UK companies produce some excellent products, and this will continue to grow as our manufacturing gets stronger, our stock levels are still very good, so we are not worried at the moment.

“The challenges for 2023 are really down to the economy,” says Jason, “if we continue to talk ourselves into recession then it will happen, but most manufacturing sectors are still going very strong and as long as we can get supplies in then demand will continue to be there. In terms of products, we have an exciting range of laser products arriving in February 2023, so we are opening up a new market place for ourselves in this sector,” concludes Jason.

01282 870077