Ooma:design specialises in architectural joinery and high-end, bespoke furniture design. From conception to design, no two projects are the same, leading the Wiltshire-based company to source fixings that not only boast impressive manufacturing credentials, but also offer flexibility and innovative design opportunities. For the craftsman at Ooma:design, this has led to a longstanding relationship with Swiss fixings specialist, Lamello.

Ooma:design cabinetmaker, Michael Cadwell

"Our business is extremely design-led,” begins Michael Cadwell, cabinetmaker at Ooma:design. “Instead of being steered by our manufacturing processes, we put design first. It might be seen as a more complicated process, but it allows us to create hand-crafted pieces that are true originals.

“To achieve this, we need to be able to rely on each and every fixing we use and know that they can meet our high expectations every single time. Using versatile brands like Lamello makes this achievable and allows us to do things our way.”

Any craftsman at Ooma:design will tell you that it takes a lot of skill to create something that is seamless. This is why the team uses a wide range of P-System fixings to suit individual projects.

“We tend to favour Lamello biscuits in our bespoke cabinet designs because they guarantee our panels will come together lush,” explains Michael. “We don’t need to spend time sanding or planning to achieve perfection because we know it’ll be spot-on every time.

Ooma.design use a wide range of P-System fixings to suit individual design projects

“More traditional methods would see us using glues and screws to achieve the same look, but this would mean having to spend time watching over the product to see where the base would meet and acting quickly if there was a possibility of it going wrong. It can be a very manic process – that’s why joiners get the ‘glue sweats.’ When there is a Lamello biscuit slotted into place, the uncertainty is taken away. All you have to do is make a jig, and off you go. It allows us to complete jobs faster without compromising on accuracy.”

Lamello’s magnet-driving Invis connector has also become a firm favourite, thanks to its completely invisible design and impressive clamping force of up to 250kg per connector.

“We used it recently to join a kitchen worktop made of two very large sheets,” says Michael, who oversaw the installation. “The results had to be seamless and installation quick, but it was difficult to join because it was cornered in by a wall. Because of this, the clamping force needed when using traditional gluing methods would have been near-impossible to achieve, but Lamello’s Invis pulled the sheets together perfectly without the need for any glue. It’s completely invisible to the customer and offers the utmost strength.”

Lamello’s verticality has also changed how the company thinks about things, offering the flexibility craved by the company’s creative team.

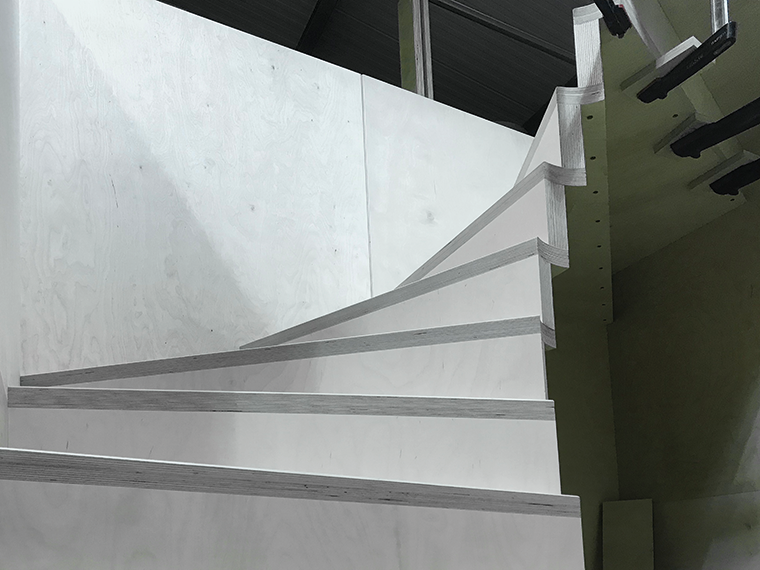

“The fixings give us so many design options,” says Michael. “We were recently commissioned to create a very tight, square-shaped spiral staircase. Each tread – which measured 1500 x 1500mm – centred around a circular tube, but because of the size of the staircase, every third tread would have ended up overlapping if we couldn’t find an alternative solution that would be suitable for use in such a small working area.”

Lamello’s Divario P self-clamping connector was the solution. Using the invisible fixing, the team was able to make every third tread of the staircase float, leaving the fitters to simply slide them in around the other parts on site. And, because the Divario P clamps the components during insertion to create a tight joint, it was easy for the fitters to insert the pieces without leaving unsightly joins.

Lamello’s Divario P self-clamping connector proved the solution for this tight staircase design

Without Lamello, we would have had to had to have used loose tongues, which would have taken considerably longer and the immediate results wouldn’t have been as good,” Michael explains. “The Divario P was a modern-day hero in this application.”

The same can be said for much of Lamello’s P-System range. Depending on the application and what the customer wants to achieve, there is a host of solutions on offer.

“The Tenso P and connectors are perfect for fitted furniture that needs to stand the test of time, whereas the Clamex is ideal for items that need to be re-assembled on site quickly without affecting the fixings’ rigidity,” Michael continues. “We tend to use the Clamex P alot when we’re working with big structures that need to fit together perfectly on-site, or on items that may need to be moved later down the line, as it doesn’t require any glue.”

Reflecting on his experience of using Lamello’s P-System, Michael adds: “Lamello allows you to achieves things that you shouldn’t be able to do when using more traditional techniques. Lamello products allow us to achieve perfection.

“It’s a big statement to make, but Lamello references the best. You have to buy into Lamello like you would any system, but it’s a worthy investment. For us, we have no time to waste on middle-of-the-road products, and our designs need to be right first time. Our customers expect the very best, and we need to deliver.

“Lamello has been a part of my entire career, but the results never fail to amaze me. It’s a pleasure to work with such great products, which allow cabinetmakers to achieve new possibilities.”

0789 1025 646

www.lamello.com