Gloucester-based DT Solutions is an established design and product development company with a breadth of experience using a wide range of materials to a broad customer base. The company primarily provides CNC cutting and routing services for companies and individuals that require 2D or 3D machined wood, MDF, plastic and acrylics, high-pressure laminates and metal components.

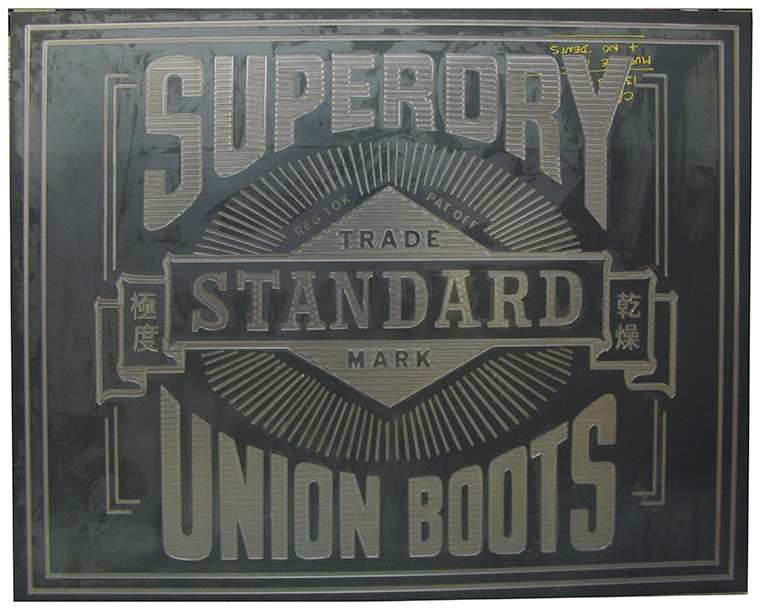

The company’s CNC machines are complemented by a powerful laser engraver which is suited to cutting, engraving and etching, enabling it to fulfil almost any criteria. DT Solutions has a broad experience of working with a range of manufacturers making modular furniture, kitchens, educational and play equipment, signmaking, letter cutting, pattern- and jig-making and PoS units – and these are just some of the company’s standard solutions repertoire.

The current machine capacity includes CNC machining centres, CNC routers, CNC turning, CAD/CAM systems, and laser cutting and engraving (maximum bed 900 x 600mm).

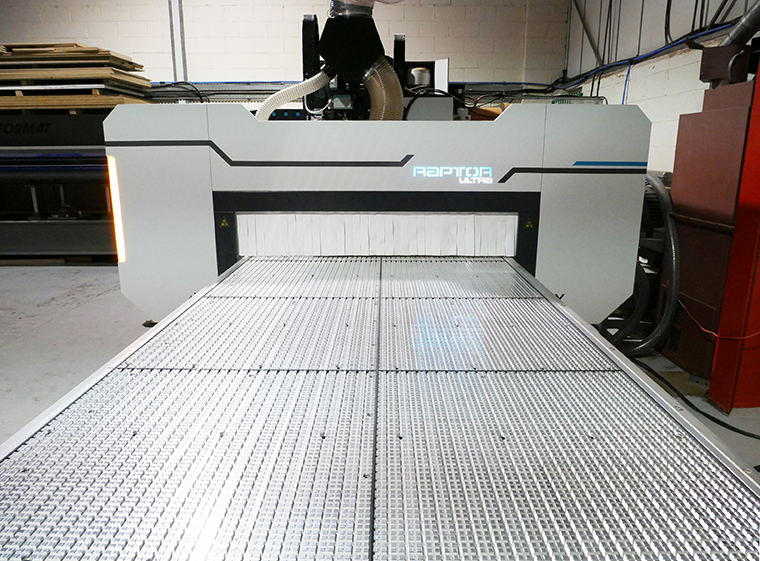

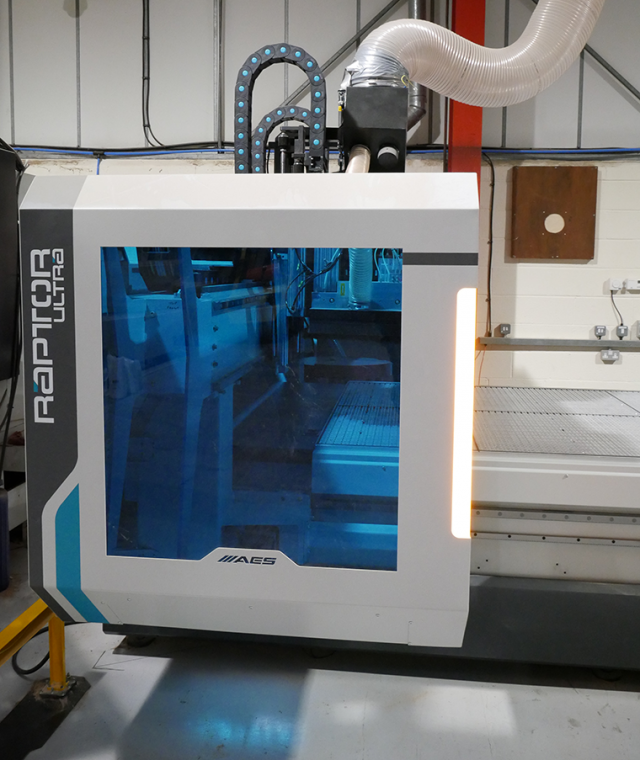

The company’s latest acquisition is an impressive AES Raptor Ultra 1632 heavy-duty, high-speed, flatbed CNC machine, ordered from AES’ exclusive UK agent, J & C O’Meara.

DT Solutions’ company director Matt Crowley describes the reasoning for this type new machine: “Primarily, we needed extra capacity, and with five existing CNC machines across our two units, and with a large element of our work for the building industry, we wanted something that could readily cope with the tough demands of that kind of work. Secondly, we needed a machine that would work with our Alphacam software.”

Carl O’Meara takes up the story: “DT Solutions was a particularly interesting job as they were already running a number of other CNC machines, so were well versed as to the capabilities and what they wanted from an additional machine. As their company name suggests, they are also a solutions provider, so deal with many different materials including HPL, TRESPA, plastics, MDF and MFC.

DT Solutions’ director Matt Crowley with his latest acquisition, an AES Raptor 1632 heavy-duty, high-speed, flatbed CNC machine

“We first met DT Solutions at the W18 woodworking machinery exhibition, where they expressed interest in the AES Extreme we had on display – and also met John Edmonson, who does our software training.

“Initially, John visited DT Solutions on several occasions in a software applications CAD/CAM training capacity to get them up to speed on their programming and manufacturing techniques, as they were already running four CNC machines.

“From this initial contact at W18, DT then arranged to visit us, as they said they were impressed with the build of the machine we had showed at the exhibition and wanted a more in-depth demonstration of the machine we have set up in our showroom, along with a discussion about the services and support we offer.

DT Solutions cuts wood, plastics, acrylics, laminate, metals and composite on its high-precision CNC machines

Some of the varied products DT Solutions creates

“This resulted in a second visit a few weeks later, where DT wanted to run some of their work on our machine using their own material, programs and tooling – and based on certain restrictions on their existing machines, DT wanted further technical information about the Osai controller and additional features of its built-in software.

“The second visit to J & C O’Meara’s showroom resulted in an order for the very-latest AES Raptor Ultra 1632, which was delivered with the following specification: a 3200 x 1600mm working area; a 12-position rotary toolchanger mounted on the Y axis; and an HSD drill box with 10 face drills, end boring to all four sides and grooving saw.

In addition, this Raptor was specified with a new Vacuboost system, which delivers 10 x the hold strength compared to a standard vacuum bed. It is described as an ‘intelligent vacuum’, with the bed split into eight vacuum zones, with two Becker vacuum pumps – one 250m3 working across the whole table, plus a second 250m3 pump which, using smart technology, follows the router head, giving the full 250m3 power to the zone in which the router is cutting.

Interestingly, Matt was originally looking at a mid-spec machine, but once he had added on various options that DT Solutions needed, it became clear that an even higher specification machine, in the shape of the Raptor 1632, could be his for a similar outlay – with the crucial benefit that this machine was designed and engineered even more robustly than AES’ standard machines already are.

DT’s Raptor also sports the latest HMI screen on the Osai controller, which gives a visual representation for the program to be run, and has the option of being able to see and edit the machine code, thus allowing the operator to pause a program, park the router to allow inspection of the work, resume a running program or run just a part of a program.

“As DT Solutions runs Alphacam as its preferred CAD/CAM solution, and as they are so diverse in their production, they needed the utmost flexibility to allow full benefit from a machine,” points out Carl. “Additionally, on the programming, DT opted to choose the Z level to allow them to choose to work from either the bottom or the top of the work.

“The machine was delivered and commissioned, with both our engineers also working with the AES technicians to ensure a smooth integration with minimum disruption to the customer.”

Matt has been impressed with the effort, commitment and expertise of the J & C and AES teams, saying: “From the initial meeting back at W18, through the demonstrations, installation and onboarding, the support that’s been provided with this machine has been first-rate.”

Matt says he has direct access via WhatsApp to a group of four AES engineers, plus Carl and his team, and the Alphacam support.

“With this team of people as a resource, nothing stands in the way of us running the Raptor to its fullest extent,” he says. “Even the smallest of queries is dealt with calmly and efficiently.”

Following the success of DT’s Raptor, Matt says he is reviewing the company’s older CNC machines with a view to possibly replacing one or more of those with another AES product.

He concludes: “We are delighted with the Raptor. It has delivered the capacity and capability we had planned – and as far as Carl and his team are concerned, and the AES team, they made the process very efficient.”