Thanks to the ultra-efficient extraction system installed by Dust Control Systems, employees at Aquapac have an enviably-clean working environment – even with high-speed woodworking machines in continual operation.

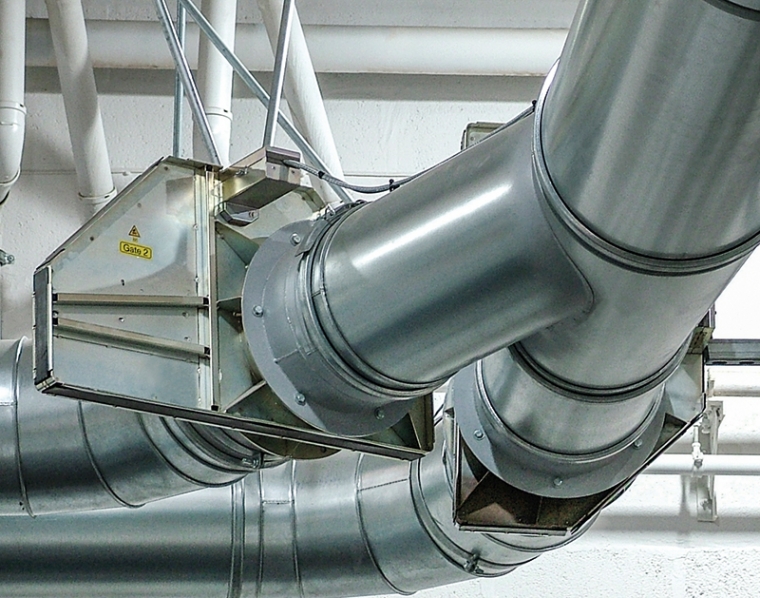

ATEX-approved 40,000m3/hr capacity NFKZ3000 filter unit at Aquapac – supplied and installed by Dust Control Systems

Dust Control Systems has supplied and maintained dust extraction plant for Scottish furniture manufacturer, Aquapac, for over 15 years and, when the decision was made to relocate the business from Glasgow to Cumbernauld, managing director Stephen Connachan had no hesitation in asking DCS sales director Melvyn Bathgate to survey the new premises and put forward proposals for design and installation of a new dust extraction system.

Established in 1995, Aquapac is geared to panel production, and manufactures ready-to-assemble, flat-pack furniture for a growing customer base that extends throughout the UK and Europe, and as far afield as North America, Australia and New Zealand.

In its early days, the company specialised in the manufacture of bespoke cabinetry for the pet industry and today, although Aquapac also produces wooden panel furniture products for hotels, offices and student accommodation, a large part of the business is derived from the manufacture and export of bespoke aquarium and vivarium cabinets.

Investing in the Cumbernauld property has provided Aquapac with a workspace of around 50,000ft2 – ample space for its arsenal of high speed machinery; including a beam saw, three edgebanders and three CNC machining centres. The facility also provides space for storage of raw materials and a packing line where sets of panels and associated fittings are boxed and palletised ready for dispatch.

And, with plans to build turnover through continued development of the niche pet furniture market, as well as gaining a growing share of the domestic furniture market, the company also expects to increase staffing levels appreciably over the next couple of years.

Although Aquapac operates a double-shift system, with panels in continuous production, loading and off-loading panels, switching machining programs and other inevitable pauses in the manufacturing cycle, means that different machines are constantly coming on- or off-line.

Traditionally, an extraction system will run at full power from the start to the end of the day; constantly extracting from machines whether they are in use or not.

To optimise extraction efficiency, and maximise energy savings for Aquapac, the DCS proposal included the installation of an Ecogate extraction-on-demand system.

With hundreds of installations in operation around the world, the proven Ecogate technology controls power output to the fan – automatically adjusting fan speed, in real time, to exactly match the factory’s changing extraction requirements throughout the working day and, when all machines are powered down at the end of the day, Ecogate automatically shuts down the extraction system.

At Aquapac, the extraction fan is powered by a 75kW direct drive motor with a maximum speed of 1500rpm. Operating the fan at full power, for five days a week, would consume in excess of 300,000kW of electricity in 12 months.

“By installing Ecogate technology, DCS have calculated that our energy usage will be less than half of that,” comments Stephen Connachan, “and the savings generated will be sufficient to recoup our outlay on the system in less than two years – then those savings just continue for the lifetime of the system.”

Filtering the dust-laden air is an externally-sited NFKZ3000 chain filter, with patented antistatic superbag filter media; integrated regeneration fans provide reverse air cleaning of the filter bags. This compact, cost-efficient modular unit is manufactured from galvanised steel, is virtually maintenance-free, and has the capacity to filter an air volume of around 40,000m3/hr. The unit comprises one inlet module and five filter modules, and filtered waste dropping to the base of the hopper section is continually directed by a chain and flight conveyor towards the rotary valve.

From here it is discharged, pressure-free, into a closed-loop transfer system, and a 15kW waste transfer fan delivers the waste to an adjacent sealed collection skip. The NFKZ3000 filter unit is ATEX-approved and ideally suited to handling the large volumes of waste dust material typically generated in panel manufacturing environments.

From each clean air outlet on the filter unit, the warm discharged air can be re-directed into the factory during colder weather, or extracted to atmosphere when not required.

Motorised Ecogate blast gates, integrated into the FastClip ductwork system, operate automatically as individual machines come on- or off-line and signal the Ecogate PowerMASTER unit to adjust the fan speed accordingly; optimising extraction and maximising energy savings

Airflow direction is controlled by a manually-operated gate and the return air system is protected by a fire damper with fusible link and micro-switch. In addition, and as recommended by ATEX equipment regulations, a CARZ back pressure valve protects the factory and its occupants from the effects of a pressure wave and flames travelling upstream in the ductwork, and back into the building, in the event of an explosion occurring in the filter unit.

“At Dust Control Systems we will not compromise on safety,” says Melvyn Bathgate, “and CARZ explosion isolation valves are always included in our system designs.”