According to Gary Tuddenham, managing director of Parabola Workshops: “Quality is everything.” His company, founded in 2013, is a specialist furniture manufacturer, working predominantly with the superyacht industry and residential homes. Based just outside Carlisle and working with designers in London, his work comes in through recommendation.

“Our work is bespoke, one-offs: we very rarely do anything twice,” Gary explains. “We can be working on a project for up to three to four months on a single item.” To maintain the high standards of quality, Gary recently invested in a made-to-measure Kündig Uniq-S edge sander.

Gary first saw the Kündig range of sanders at a W Exhibition, at Birmingham’s NEC. The team from Parabola took full advantage of the opportunities at the show to view a wide range of woodworking machinery in action, including Kündig sanders demonstrated by Carl O’Meara of Kündig UK.

Regarding the edge sander, Gary says: “We ummed and ahhed about it: then, after a visit to Carl at his showroom in Burscough, near Preston, we felt that we should definitely get the sander – it made sense.”

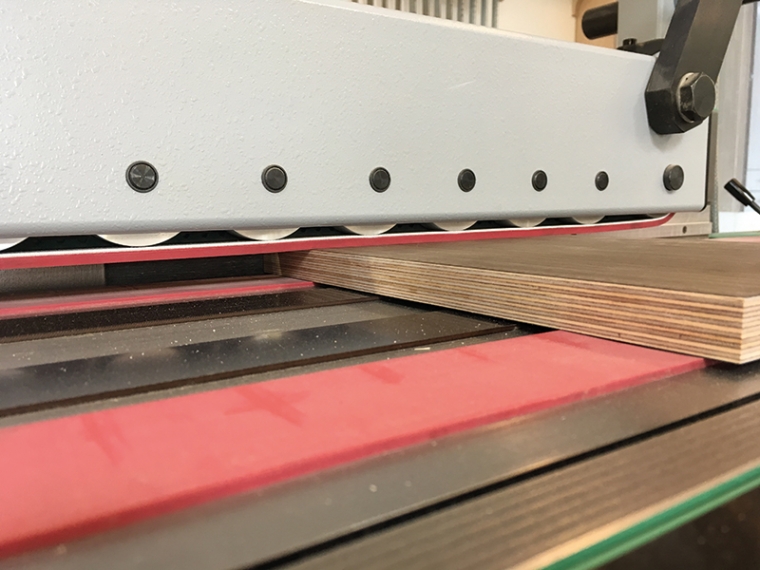

The edge sander provides significant production advantages. “We have machines that sand the faces of panels, but always spent a lot of time by hand sanding the edges. It just does not make sense when there are a lot of drawerboxes and carcasses. The Uniq-S takes the donkey-work out of everything: it is efficient.”

Gary talk of choosing Kündig: “It’s because of the build quality and the reputation. There are a couple of other manufacturers that do a similar machine but it wasn’t quite the same. For the accuracy we were looking at the sander had to be built correctly, with tiny tolerances. It had to be a rigid quality machine.

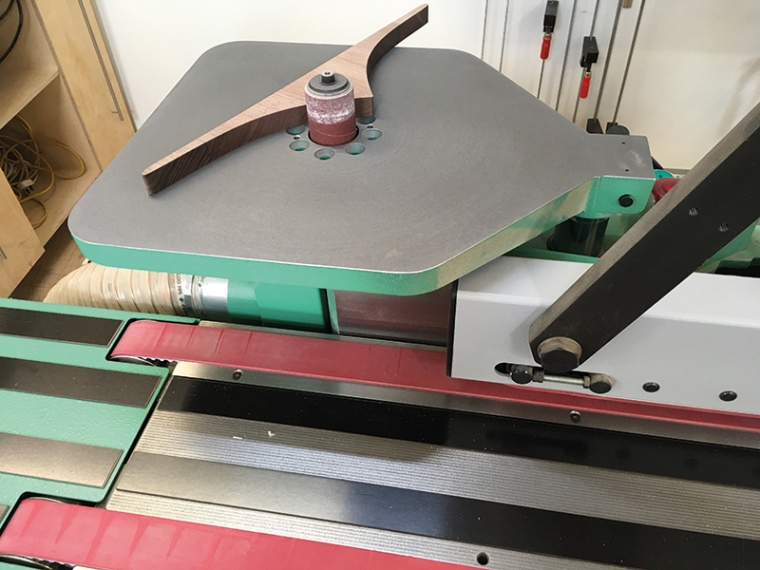

“It is very convenient. We have the edge sander in the hand workshop rather than the machine workshop. It is there when you need it, right next to the work benches.” While space was not an issue, Gary adds; “It is a nice compact machine.”

Gary selected various options, including a grooved infeed platen to allow the sanding off of veneers that have been over laid after edging; a second transport belt to allow sanding of the ends of narrow panels; a two speed motor to allow finer grade abrasives to be used; a bobbin attachment allowing internal and external curves to be sanded; and a semi round table allowing the sanding of shapes using the rubber coated drive roller on the machine.

The Kündig Uniq-S handles throughfeed sanding of small or large workpieces thanks to the integrated feed system, and can operate manually or with automatic feeding. With a table size of 1180mm x 325mm, the sander comes with two guide-pulleys for long workpieces. Pressure rollers hold the workpieces against the feed belt. The solid frame construction features heavy cast iron tables. The belt width is 150-200mm, and the belt length is 2000mm. The working level is approximately 830 mm on the sanding side and 900 mm on the side for veneer sanding. The net weight is 490 kg and the floor space required is 1150mm x 800mm.

Asked if he would recommend the Uniq-S edge sander, Gary replies: “Yes, definitely. It does everything we expected it to do.” He added: “Carl is perfect: you can talk to him, no problem, and he will give you good advice.”

0845 833 0565

[email protected]

www.kundig.co.uk