Automisation of processes, production flexibility, machining quality and reduced delivery times to keep up with increasingly faster online purchasing methods – these are the priorities for businesses involved in customised furniture design, covering the entire production process from the project to delivery. But how to reconcile all these needs?

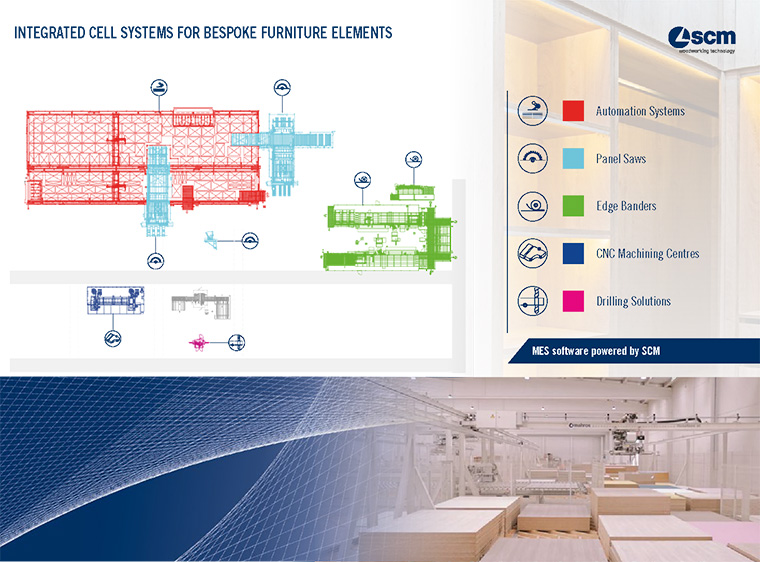

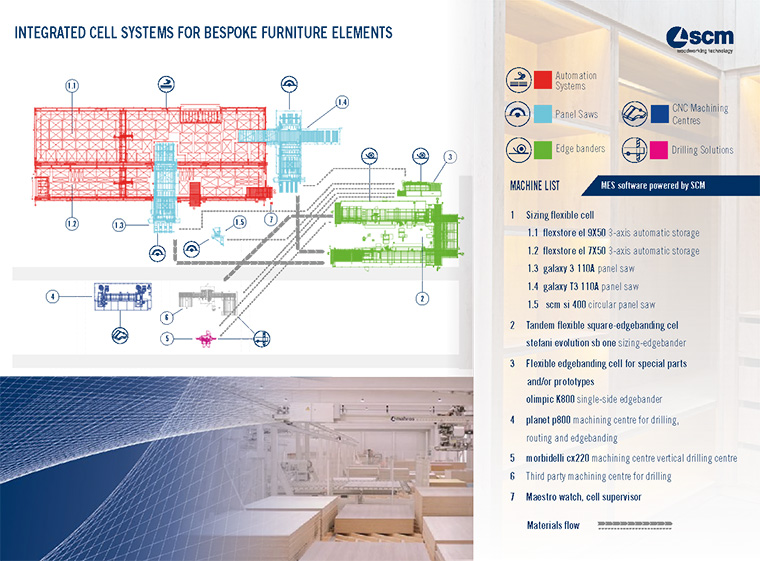

SCM offers integrated systems of flexible batch-one cells capable of meeting market trends with two results – the optimisation of processes and a significant reduction in costs and energy consumption.

This is the case of the solution outlined in this article, with a production capacity of 1500 pieces per shift, designed by the engineering team for a leading Spanish company in the furniture and design industry …

Sizing cell

The cell consists of two automatic three-axis Flexstore el storages, integrated with two Gabbiani g3 and Gabbiani gt3 sizing machines that both perform well in terms of speed and machining quality. There is also a machine for cutting the smallest offcuts and finest material – the Class si 400 sliding carriage sizing machine.

Not only does the system have a separate magazine for managing the rejects that are automatically reintroduced, but it is also highly versatile and capable of adapting to production needs.

While the three sizing machines are equipped with specific functions, they can be interchanged depending on the amount of material being machined and the kind of reusable offcuts.

Integration with the Maestro active watch cell supervisor software and the Maestro store magazine is also key, as they allow storages outside of the cell to be managed, used to store materials in other areas of the factory, or for smaller or fine panels.

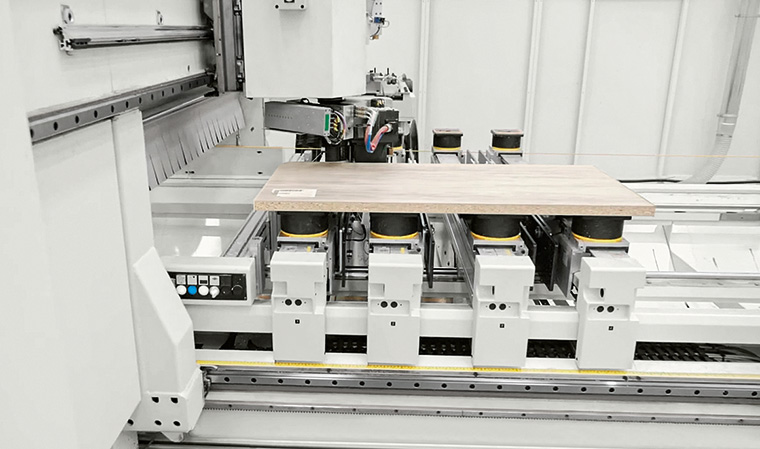

Square edging

Flexibility is the keyword – even for the square-edgebanding cell consisting of two Stefani sb one unilateral edgebanders with automatic feed system, for panel sizing and squaring.

The strength of these solutions, designed for big industry lines, is their ability to work panels in sequence and JIT with different sizes, applied edge and machining, with small or pure batch-one batches. These machines are fully electronic and can achieve three radii automatically thanks to the Multiedge system. They have 24 roll-edge magazines, ensure a rapid and automatic change of glue colour and perform routing inside and outside the feed tracks.

The Maestro active watch supervision software is also key – thanks to the barcode on each panel, the software can match the right machining program and trace and control all the process stages to each piece, as well as further controlling functions and production reporting.

The edgebanding of special and prototype pieces is executed in another cell, consisting of an Olimpic k800 unilateral edgebander with Touch 7 control interface and panel return.

Standalone solutions to complement the process

SCM proposes two state-of-the-art technological solutions:

• The Morbidelli p800 drilling, routing and edge treatment machining centre, ideal for machining and achieving JIT panels ready for assembly. It is highly versatile, and can be used in two ways: to apply the shaped edging to panels already squared; or to drill, rout and edge the unfinished panel. If the pieces being machined are mainly curved, the machining centre allows the passage in the squaring/edgebanding cell to be skipped, proving itself to be a real wild card in any factory.

Some of its key advantages include its extremely fast set-up times, thanks to the Matic automatic table with suction cups and bars that move automatically and simultaneously with anti-collision check.

• The compact CN Morbidelli cx220 drilling centres for machining special and prototype panels. Its worktable allows the user to drill even delicate surfaces, with impressive finishing results. The new, shaped, hold-down grippers mean that panels can be machined even in positions inside the grippers, greatly reducing cycle times and optimising workpiece clamping.