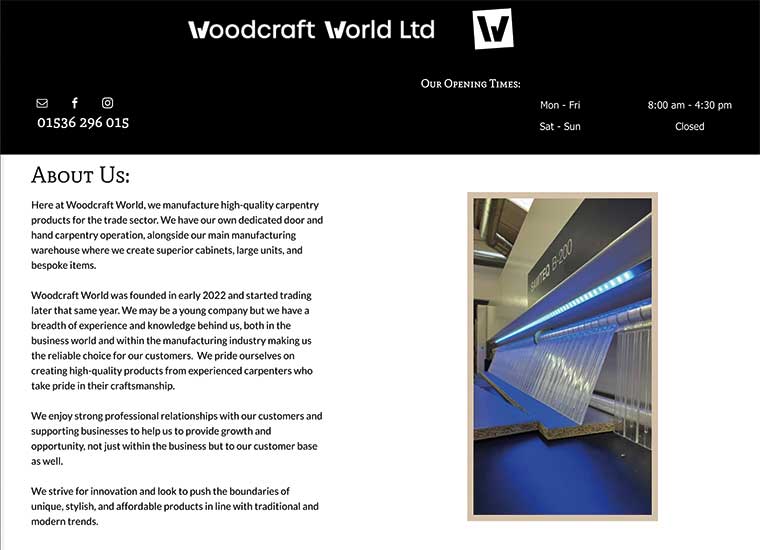

HOMAG SAWTEQ B-200 Air Table

.

Sarting a brand new business venture is never easy. Anyone embarking on a start-up company in the last 12 months or so, however, has had to face the added challenges of supply chain issues, the aftermath of COVID and Brexit restrictions.

“It’s certainly been an interesting process,” says Brett Manchett, factory manager of the fledgling Woodcraft World joinery business based in Kettering, Northamptonshire. He continues, “We began trading in early 2022 and to go from zero to where we are now in less than a year is amazing.

“Once our directors, Kevin Baker and Andy Hubbard, had made the decision to set up a new joinery business it was a question of how quickly could we get all our ducks in a row ready for launch.

“As a company, we believe the most important piece of the jigsaw is investing in the best machinery available. I’ve been involved in the woodworking industry for over 15 years and during that time I have gained experience of working with a number of the leading machinery brands.

“From the outset we made the decision to buy what we consider to be the best equipment on the market. Without doubt, HOMAG machinery is head and shoulders above the competition. Not only are the machines exceptionally well built, but they are also technically the most advanced and reliable machines money can buy.

“If you want to consistently produce top quality products you need to invest in the best machinery and with HOMAG, that’s exactly what we have done.”

HOMAG EDGETEQ S-240 entry level edge bander

The shopping list

“To create our high performance workshop we wanted a beam saw, an edge bander, a CNC drilling centre and a cabinet press. To achieve this meant working closely with HOMAG to make sure we could get the equipment delivered when we wanted it and all at the same time. This was no easy task, but HOMAG bent over backwards to help.

“They had a SAWTEQ B-200 at a show in Barcelona and were able to secure that for us along with an EDGETEQ S-240 edge bander and CABTEQ S-200 that were available from stock.

“The extremely popular HOMAG BHX 050 drilling CNC proved a harder nut to crack; the lead time for a new model from HOMAG didn’t fit with our schedule. After a bit of searching, however, we were able to source an excellent second hand machine which could be delivered at the same time as the new HOMAG kit.”

HOMAG – a team you can trust

“I must give a big shout out to the HOMAG engineers who installed the equipment and trained our team. They were absolutely brilliant. Nothing was too much trouble; engineers Ian, Carl and Colin made sure we were totally happy with the machines before they left.

“On the training front they were extremely thorough, running through everything with our four operators, including parts ordering and machine maintenance. They were so helpful and left no stone unturned which meant we were able to go fully operational almost immediately.

“One of the benefits of the HOMAG equipment is the quality of the software that controls the machines. Whether its woodWOP, CADmatic 5 or other control systems, they are all intuitive and easy to learn. The simple touch screen operation is quick and instinctive to use so our operators can move from one machine to another with ease.”

HOMAG CABTEQ S-200

Quality results and reliable performance

“Each HOMAG machine has performed superbly; the SAWTEQ B-200 is extremely fast and precise, consistently cutting panels to very high accuracy. Although the edge bander is an entry level machine, the quality of the edge finishing is exceptional and we consistently achieve a really clean finish.

“All this good work can be wasted if the cabinets we make from the panels are not glued and pressed absolutely square. This is where the CABTEQ S-200 comes into its own. It is easy to operate, precise and fast; it enables us to produce finished cabinets which are always true.

“What we’ve achieved as a business in our first year we couldn’t have done without the help of the HOMAG team. To a person, they have a positive attitude and get things done. If issues occur, most are sorted out online. If an engineer has to come out, however, they are usually with us inside 24 hours. We couldn’t be with a better partner,” concludes Manchett.

For a demonstration or further information HOMAG woodworking machinery and software, contact Adele Hunt at HOMAG UK on 01332 856424, email: [email protected], or refer to www.homag.com. For Woodcraft World email: [email protected] or call 01536 269015.