Now in its fifth generation of family ownership, Royal Warrant holder Stoneham Plc specialises in stylish, luxury kitchens. Its bespoke kitchens are custom designed to the client’s specification and built using the finest materials in its Sidcup based state-of-the-art manufacturing facility.

“We’re passionate about our products,” explains works director, Mike Stoneham. He continues, “By combining traditional British craftsmanship with the latest manufacturing technologies we consistently deliver premier quality goods with meticulous attention-to-detail.

“In our minds, a vital part of business success is developing strong relationships with our suppliers. Homag is a case in point. We have invested in its equipment and software for over 40 years now, and the service and support we get from them is excellent.

“Our Homag area sales manager is Charles Smith, and a more genuine ‘nice guy’ you couldn’t wish to meet. His knowledge and experience of our business, the trade and, of course, Homag machinery and software, is beyond compare. He never tries the ‘hard sell’ approach and any advice he gives, you know has been painstakingly thought through.”

The need to increase capacity

“Over the years, we have invested in a lot of Homag equipment, from sanders and CNCs to edge banders and beam saws. We first acquired a CNC in the early 1980s, but it was in 2016 when we introduced one of the biggest game-changers to the business – the Venture BMG 5-axis CNC.

“This machine enabled us to make more unique and difficult-to-manufacture products. In the long run, this has set us apart from our competitors and given us a clear advantage in the market.

“In 2019 we began looking at the necessary investments to take the company to the next level and increase our capacity further. Top of our list was an advanced CNC and so we began researching the market to see what was on offer.

“Whilst there are several impressive machines out there, none offered us the complete package that Homag could. Probably the biggest difference was software. We have been using Homag’s woodWOP software for many years and have found it to be versatile and easy to use. Our experience with other manufacturers was mixed; either they relied on third-party software or their own software just wasn’t as good as woodWOP.

“Once we’d decided to go with Homag we sat down with Charles Smith and Homag’s CNC expert, Phil Pitchford, to map out the specification for the machine. As always, we were looking for a solution that would not only increase our existing production capacity, but would also future-proof the business by enabling us to produce new and innovative products.”

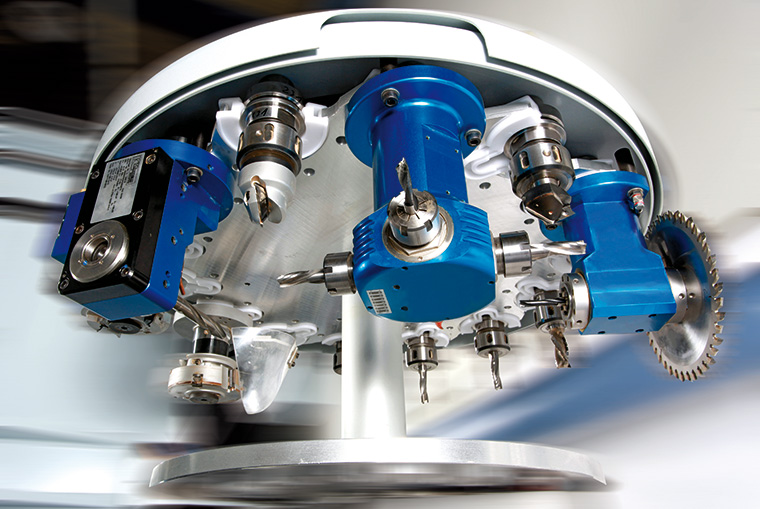

The Centateq P-210 automatic tool changer offers Stoneham PLC speed, versatility and flexibility

The Centateq P-210 CNC processing centre

“Our deliberations led us to invest in a Homag Centateq P-210. Before making the final decision, however, we flew out to Germany to spend time with Homag’s engineers and see the machine in action.

“This was really useful, but there is nothing quite like talking to an end-user and so Homag arranged for us to visit a customer who had been manufacturing with the Centateq for some time. Here we were able to talk directly not only with the business owners but also, more importantly, with the actual CNC operators. These guys who work on the machine day-in, day-out, tend to tell you what they think, warts and all.

“The feedback from the trip was incredibly positive and so we placed an order for the Centateq P-210. Other than the software and programming side of things, the big pluses for us were the machine’s capabilities. Our work demands a lot of tool changes and the P-210 has the facility for big drill blocks offering speed and versatility in both routing and drilling. This model is also slightly taller than our existing CNCs which surprisingly, perhaps, makes a big difference to its production capabilities.

“The Centateq P-210 has delivered everything we were looking for and more. For example, we can now produce a solid MDF door in six minutes; previously, using a traditional ‘in-frame’ design, it took us much longer and required several different processes. In addition, the P-210 has significantly reduced material wastage and, because a solid door doesn’t bow or twist, it has eliminated painting issues in the spray shop.

“Since the Centateq P-210 was installed we have also ordered a Drillteq V-200 from Homag. This was required to increase our drilling capacity. We already have an original BHX 055 vertical CNC. It is such an easy machine to use, there’s no set-up required; we have a barcode reader in front of it and it’s simply a case of point, shoot, load and drill. It was, therefore, an obvious decision to order another.”

A true partnership

“Everyone at Homag is extremely receptive, easy to get hold of and willing to help. Theirs is definitely a ‘can-do’ attitude; they are always thinking about long-term relationships, never the short-term fix to get them off the hook or sell a machine.

“Naturally, as the global market leader, Homag is rarely going to be the least cost option. When it comes to value for money, however, no other brand comes close. Add to this the comprehensive back-up and service support you get from them, and we believe it makes an unbeatable package.

“As the marketing suggests, Homag sells solutions, not machines. That is such a refreshing approach and one that ultimately builds trust,” concludes Mike Stoneham.

For a demonstration or more information about Homag’s solutions, contact Adele Hunt at Homag UK on 01332 856424.