The last 18 months have been a roller coaster for many businesses, with the industry having to adapt quickly during a time of economic uncertainty. For many, this has resulted in temporary or even permanent business closures but for TBS Poly, it’s been its busiest on record, as it’s continued to supply and fabricate plastic sheet materials to small tradesman, large merchants and contractors throughout the pandemic. It’s this success that has resulted in the family-run business investing in four new machines, including a new Striebig Control vertical panel saw from Leicester-based TM Machinery.

“Our previous Striebig vertical panel saw was 15 years old and, pre-Covid, it was running up to 12 hours a day, five days a week,” explains William Gresswell, business development at TBS Poly. “It’s safe to say it was the most-used piece of kit in our workshop, cutting on average three tonnes of sheet material each day – including Polycarbonate, Acrylic and Trespa, PTG, PVC, GLP, aluminium composite and laminate board – and up to 20 sheets at a time.”

But, when the country went into its first lockdown in March 2020, business was impacted immediately. “As our competitors shut down and the threat of material shortages turned into a reality, we decided to buy as much stock as we possibly could from our suppliers and competitors,” reflects William.

“I’m sure people thought we were mad but our gamble paid off. We were selling sheet material faster than we were able to offload it from our lorries. Demand for plastic safety panels, service screens and dividers skyrocketed. We went from cutting three tonnes of plastic sheet material a day to over 10 tonnes a day on one 15-year old Striebig – and it never let us down once.

“We were working it around the clock, only stopping for material change overs, and breaking sales records in the process. It was a true workhorse and it did us proud but it also made us reassess our business model.”

TBS Poly use a wide range of sheet materials measuring up to 6m x 2m and up to 20mm thick

Whilst William admits orders for cut-to-size sheet materials have started to ease (but still remain considerably higher than previous years) ongoing plans to expand the company’s Hertfordshire-based facilities in order for it to hold up to three month’s-worth of sheet material at one time and house three newly-purchased three-axis CNC machines, are well underway and the need to invest in new technology is more necessary than ever.

William says: “Covid made us realise what we needed to invest in going forwards. We needed a saw that could increase our throughput, streamline our production and be more efficient in terms of material yield. We simply didn’t have the room to buy a second saw but we were in a position to upgrade to a newer, automated model. We didn’t need to look around. We’ve had a good relationship with TM Machinery for over 20 years – they service our machines every year and we trust them. We also know what we’re getting with a Striebig vertical panel saw: a robust machine that offers pin-point accuracy, guaranteed.”

The automated Striebig Control offered TBS Poly the perfect solution and, with no delays in shipments during the pandemic, TM Machinery were able to dismantle the old saw and install the new one in just eight weeks.

Thanks to its wealth of automated features – including fully automated cut cycle, automatic beam and saw head positioning for horizontal cuts and a new 12in touch screen computer, it has made TBS Poly’s cutting operation around 25% faster.

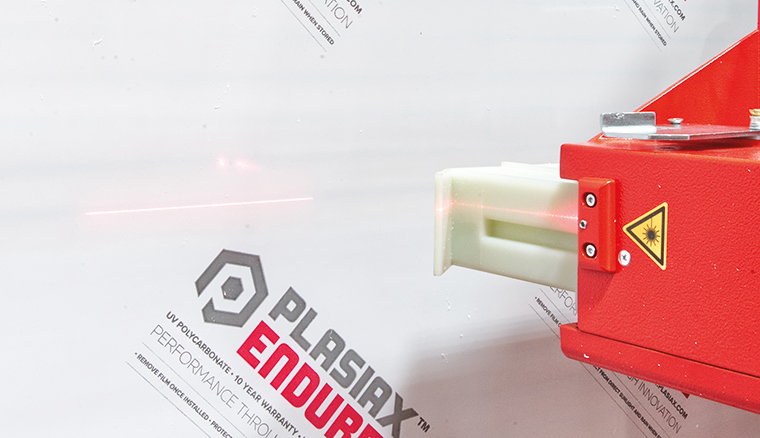

“As well as its handy standard features, like its laser indicator for horizontal cuts and digital measuring system, we also opted for automatic length stops (electronic positioning system). These really are worth the extra cost,” says William.

“Once you’ve programmed the size of the panel, the stops automatically move into position. There’s no manual adjustment needed. It also lets you know if the stop has been knocked at any time during the handling process, saving you valuable time and material waste if something were to move accidently. Strip cuts have also been made easier and faster because of the strip cutting gauge and, with the saw’s computer able to save jobs and common cut sizes, repeating regular work has become much simpler, reducing set-up times by approximately 35%. The new Control also works efficiently with our Maxcut V2 cutting programme, which creates cutting lists designed around our stock sheets and off-cuts.”

William adds: “The new Control has definitely lived up to expectations and offers precise, accurate cuts. Features aside, confidence in the machine and its after-sales team always has a huge part to play in any purchase we make – it’s a big intangible benefit and one that we cannot afford to overlook.

“We have every confidence in our saw’s capabilities and that reflects in our level of customer service. Going forward, we want to be known as the go-to supplier of polycarbonates in the UK, increasing our stock levels and variety of polycarbonate that can be cut, shaped, edged and drilled before being shipped direct to manufactures. This will only be achievable with the best machinery in place and this is exactly why we’re continuing to invest in Striebig.”