LundHalsey’s Rover A FT 2231 CNC machining centre with loading complete with off-loading tables and a Winstore 3D K2 automatic board storage and retrieval system

Successful control room furniture manufacturer LundHalsey realised – its production capacity was not keeping up with demand – it needed to find solutions. What if your business was a roaring success? From the outside, the order book is full but frustratingly from the inside, you’re finding it difficult to cope with that demand, maintain customer service standards and return a healthy profit. By combining the desire to prosper with the courage to radically change the way a company operates, business transformation has never been more meaningfully applied than at LundHalsey.

Operating in the highly professional market of control room furniture, operations director, Rob Parker reveals: “We had a history of continuous growth, especially in export markets but we reached a point where we didn’t have enough capacity. Success was grinding us to a halt.”

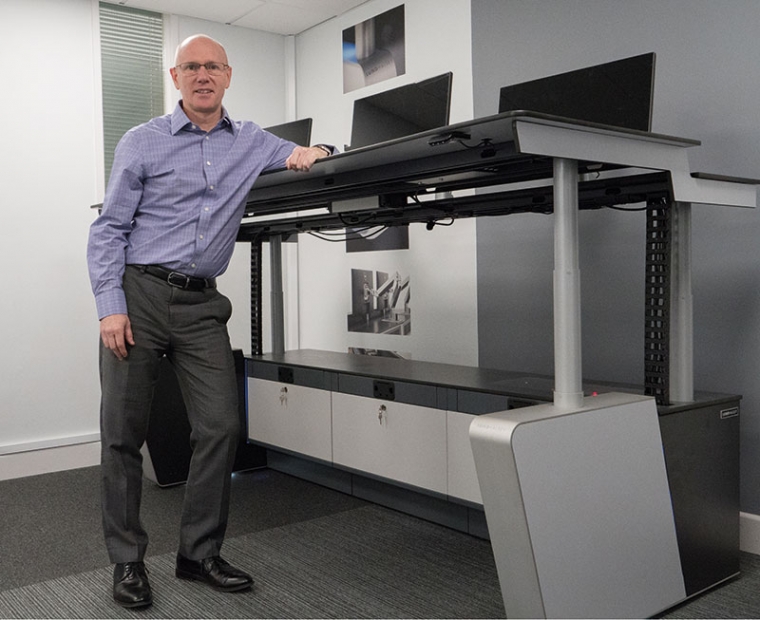

LundHalsey’s operations director, Rob Parker, by one of the company’s motorised, height-adjustable control desks

LundHalsey had to re-model the whole business and that began with the brave move to re-engineer its product.

“We made the key decision to change from timber based products such as MDF and MFC to Compact Laminates, in an attempt to really hit the market with quality and style. The benefits were less space requirements, maximum quality and reductions in the volume of component parts and product variations.

A typical LundHalsey control desk

“Our drive for efficiency was focused on our ability to produce quickly. Using Compact Laminate, we could produce a finished component in one operation, eliminating the need for secondary operations such as edgebanding.”

“Working closely with Biesse to prove the processes and material viability, we purchased a nesting cell – a Rover A flat table CNC machining centre with loading and offloading tables – as well as a Winstore 3D K2 automatic board storage and retrieval system.

“The results are astounding. We have seen an increase in efficiency of over 50%. Our team can’t believe what we can now achieve in terms of output. We’ve now transitioned from a highly skilled labour intensive operation to an assembly environment and we have re-deployed people to achieve those efficiencies.

“Biesse’s bSolid software is also excellent – it does exactly what we want it to do and we now use that exclusively, saving around £45k in post-processing software.”

There were several other key factors in LundHalsey’s decision to choose a Biesse solution.

“We’ve had a couple of Rover ATS machines for over 10 years,” Rob continues: “so Biesse’s reliability was a given. Total Care was also an influencing factor with the peace of mind that a five year warranty and service plan provides, especially now that the Rover A and the nesting process is business critical.

“However, I believe the main factor was that Biesse listened. They seem to work on the principle of ‘tell us what you want to achieve and we’ll help you to realise it’. The Winstore has been a revolution for improving the efficiency of our handling, storage and loading and we instantly saw the benefits when Biesse took us to one of their customer’s sites to see the solution for ourselves. We now have scalability.

“All in all the sales process was very consultative and installation was slick and professional, with excellent support. We’ve put a massive amount of effort into transforming our business and the knock-on effect has been tremendous.

“Not only have we been awarded the Queens Award for Enterprise in Export Growth, as 95% of our product is exported, but we are also proud to welcome customers to our new facility. In fact we obtained the contract for the Mercedes Motorsport control room because the environment here works on so many levels, especially with Biesse’s automated solutions.”