For over forty years, A.S.H. Plastics has been producing premium quality point of sale displays and precision components for sectors ranging from retail to defence and beyond. Located in Wolverhampton and with a turnover of £4.2m, the ethos of the company is based on combining engineering excellence, a commitment to customer service and an insistence on utilising the latest in technology.

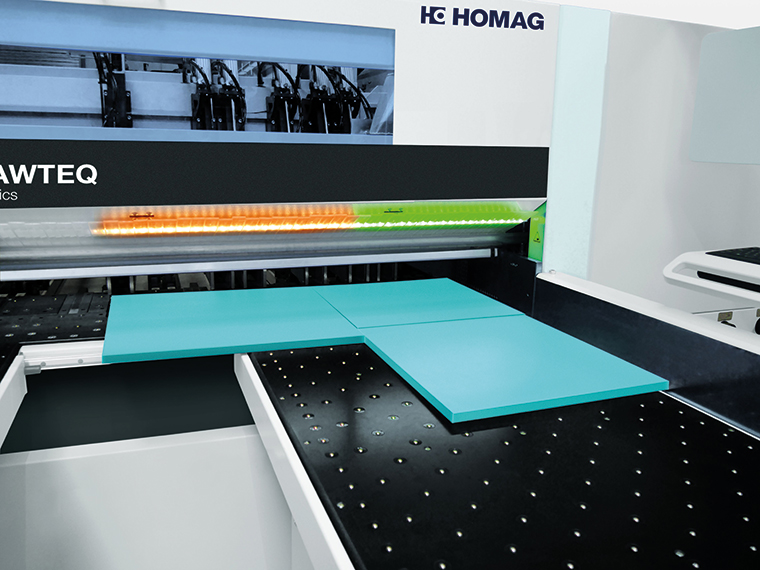

Its ethos was a key reason the company invested in a HOMAG SAWTEQ B-200, as managing director David Archer explains: “Our pledge to always provide our customers with the very best products and solutions requires we invest in the most advanced technology available.”

He continues, “We decided to purchase a HOMAG beam saw to enable us to bring under our control the tolerance accuracy of cut parts. For us to supply the best point of sale material, every part must fit together perfectly, but if there are even minor variances in the cutting accuracy it makes it almost impossible for us to consistently produce the high standard of finish we strive for with all our products.

HOMAG SAWTEQ intelliGuide

“Previously, we had contracted out the cutting of our plastic sheets, but it was hard for us to control the quality of the cutting. Consequently, we decided to invest in a beam saw from what, in our industry, is considered the best machinery manufacturing brand on the market.”

Specifying the HOMAG SAWTEQ B-200

“As part of the selection process we looked at few brands including an Italian manufacturer and HOMAG. We chose HOMAG for a number of reasons. Firstly, its reputation as the global brand leader gave us a great deal of confidence.

Secondly, the company’s representative, Matt Long, was extremely helpful and knowledgeable. We felt he understood our business needs and, more importantly, we could trust him to specify the right saw for our current and future requirements. Matt recommended the entry level SAWTEQ B-200 and it has proved to be the perfect machine for our production demands.

“Finally, the SAWTEQ’s consistent quality of cut, with regards to both accuracy and a clean finish, were very impressive. The HOMAG saw has added a new string to our bow; it has not only given us independence, but also much improved quality control.”

SAWTEQ B-200 – versatility, power and precision

The SAWTEQ B-200 is designed to cut panels horizontally with power, precision and above all flexibility. It is available in a choice of two standard models and a wide range of technology options. This enables customers to specify the machine to meet specific requirements and yet remain flexible, so the saw can grow depending on the business’ needs.

The B-200 is operated by CADmatic 5, the state-of-the-art, high-performance control system from HOMAG. It features an intuitive operating concept and is open for communication with other machines and software solutions.

This latest generation of HOMAG’s saw control system has a new assistance graphic that clearly shows the machine operator all the steps in sequence. The 3D assistance graphic supports the operator directly at the saw. Its intuitive operation shortens the training period required and reduces errors to a minimum.

The new powerTouch 2 user interface features a 24in full HD multi-touch widescreen display which is easy to use by swiping, scrolling and zooming. Many of the functions are similar to those of a smartphone or tablet and are therefore familiar to most users. Even beginners will feel immediately at ease and will soon be able to control the machine comfortably.

Effective training and ease of use

David Archer again: “HOMAG’s installation engineers were very helpful and provided the training for our staff on the SAWTEQ B-200. The saw is easy to operate and the quality of training meant that from day one our guys were able to hit the ground running.

“The machine has proved to be extremely reliable; on the odd occasion we have needed support, however, HOMAG has always responded quickly and effectively. Overall, we would expect the SAWTEQ to have paid for itself within five years and still have many more years’ service to give.

“Not only has the saw delivered cost savings and efficiencies to our production, but it has also enabled us to attract new customers,” concludes Archer.

For a demonstration or further information on HOMAG saws or other woodworking machinery or software, contact Adele Hunt at HOMAG UK on 01332 856424 or email: [email protected]