Ahmarra Door Solutions manufactures performance architectural doorsets across all sectors including education, commercial, hotel, airport and luxury residential. To deliver the quality expected at this level, the company looked to Lancaster-based Hoffmann Machine Co for a premium technology solution …

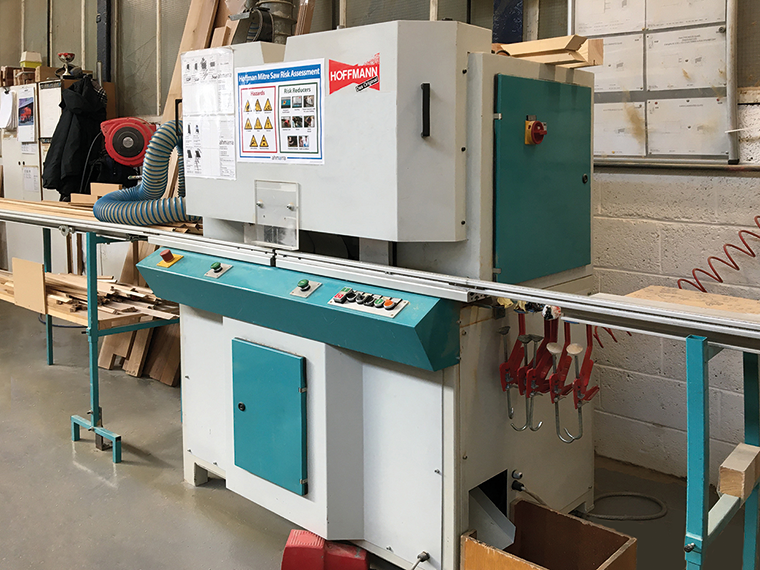

Ahmarra Door Solutions specialises in manufacturing performance doorsets for projects where complex fire-resisting, acoustic and security requirements exist – including timber-glazing bead cassettes for fire-rated doorsets, and timber panel mouldings for its range of bespoke Artisan Panel Doors. A combination of precision machinery and fine craftsmanship enables Ahmarra to meet the highest quality, performance and certification requirements. One of these precision machines is the Hoffmann MS 35-SF combination double mitre saw and router.

As an definitively innovative solution, the Hoffmann MS 35-SF delivers two clean, precision mitre cuts without break-out, to an exact length in one machine cycle. When both pieces are to be joined together or in a frame, then they can be prepared with one or two dovetail slots in precise positions in the cut faces, for jointing with Hoffmann Keys (suitable for workpiece sizes to a maximum of 90 x 90mm).

The machine can be fitted with router cutters for processing Hoffmann Key sizes W-1/2/3, making it ideal for cutting profiles for glazing beads, cornices, plinths, etc, in wood, aluminium or plastic at 45°. It can also be used solely as a double mitre saw.

The technology, developed by Hoffmann for damping vibrations of the blades, ensures the high-precision cut of the MS 35-SF, and the almost vibration-free running of the machine means that no further work is required prior to joining.

“Our Hoffmann MS 35-SF has been extremely reliable and efficient,” explains Ahmarra’s managing director, Tim Doran. “Over the many years of manufacturing, many of our machines have required replacing and updating as expected, but the Hoffmann MS 35-SF has continued to manufacture a precision product with only routine maintenance required, and we see no reason to replace it in the near future.

“This combination machine not only cuts the perfect mitres, but simultaneously routers the dovetail slots for the Hoffmann Keys. Ahmarra has a long relationship with Hoffmann, and our current Hoffmann MS 35-SF has been in operation for over 20 years, and still performs with the expected accuracy and precision that it did the day it was installed,” enthuses Tim.

Ahmarra works very closely with architects and interior designers to meet their requirements, allowing flexibility in design while retaining comprehensive fire certification in accordance with Building Regulations. Hoffmann Dovetail Keys are all accredited with FD30/FD60 ratings.

As a leading manufacturer of fire door solutions, Ahmarra believes in maintaining the traditions of its craft by preserving the skills and value of time-served, traditional bench joiners, while utilising the very latest technology in design and production methods. This way, its customers get the best of both worlds.

“Our many years’ experience of manufacturing timber doors has led us to produce a number of sector-specific product ranges, to include education, hotel and panelled doors,” points out Tim. “We specialise in working with clients who recognise the importance of developing doorset standards throughout their facilities. Significant client cost savings can be made by eliminating the need to redefine doorsets and ironmongery for each new project. We offer intelligent advice on how to make this process cost effective, simplifying what can be a very complex issue.”

A similar principle is held by Hoffmann Machine Company. When specifications such as optimisation, rationalisation and cost savings are essential aspects of a customer’s production, help can be found in its engineering services department.

The company can develop a package of measures that will result in a machine, designed to customers’ requirements, that offers efficiency, quality assurance and cost minimisation.

01524 841500

[email protected]

www.hoffmann-uk.com