Over these ensuing years STEMAS has developed to become the predominant market leader in the manufacture of special execution machinery; however, in terms of CNC Routing Technology and in particular door processing, they are widely recognised as the undisputed industry frontrunner in terms of high-speed house door processing machinery.

In the last two decades, Stemas has reputedly become the leading supplier of specialist high-speed through feed routing and ironmongery inserting systems for the door industry around the world; with many large fully automatic door line system installations in Poland, the one of the biggest house door manufacturers in Europe, as well as the UK, Israel, China, South Korea, USA.

The PERFECT-DOOR Systems, represents the first serious choice for either a small/medium producer, facing a growing demand on their production capacity, or indeed a medium to large door manufacturing enterprises in need of achieving unmatched productivity of up to 3 doors per minute and to gain a competitive edge over their market rivals.

In the UK there has been a proliferation of door manufacturers coming to the market in the last five or so years, especially the Fire Door market, each one following the exact same ‘Calf Path’ manufacturing routine as all the others, namely buying one standard 4 or 5 axis, ‘run of the mill’ CNC router after the other.

“Of course, one must start somewhere, and the traditional CNC Router is the correct starting point, no doubt about it” comments Angelo Glenn Onorio CEO of Stemas “but there comes a point in time where the ‘stand-alone CNC Routers’ start become very inefficient”

“For example,” continues Angelo “The production inefficiencies really starts to come to light once a company gets to three CNC routers, then a fourth and possibly a fifth or more even, at this point door processing with traditional 4 or 5 axis traditional routers, is really uneconomical and the manufacturer truly risks losing market and more importantly margin and profit”

Three doors per minute

“When a door manufacturer approaches ‘Critical Mass’ with his existing production capacity he must re-evaluate his door manufacturing methods and efficiencies.” Adds Lorenzo Esposito, Technical Sales Manager “It is fair to assume that a traditional 4 axis CNC, which I understand is the most common style in the UK door industry, generally takes around 10 to 15 minutes to complete a basic door process*, hinges, door locks, keyholes etc, and in many cases we have observed much longer processing times, especially when the door is being loaded on and off manually, if a company has five CNC’s this equates five possibly six men producing say 20 to 30 doors per hour”

“With the fully automatic Perfect Door System, in one hour” continues Lorenzo “One can produce around 170 – 180 doors with only one man, only in partial attendance; carrying out a similar basic door processing operation, if one calculates the extra manufacturing capacity the fully automatic perfect door system creates and the sevenfold reduction in manpower the savings are phenomenal, they run in hundreds of thousands of pounds”

The ‘PERFECT DOOR’ System, is designed as a unique modular concept, wherein the line can be built up in customised stages to suit the purchaser’s individual needs, for example, a fully automatic ‘First Stage’ system can produce one complete door in just over 45 seconds*

The ‘PERFECT DOOR’ system has certain features that traditional door routers simply do not have, nor can they be supplied, for example, in essence it does not require a full-time operator as it is a fully automatic/autonomous line, it will ‘check measure’ the door before machining starts, it will ‘talk’ in real time to the production planning dept and production managers.

The modular construct of the PERFECT DOOR system allows the customer to build up in stages the level of speed, sophistication and flexibility in a step-by-step approach so as to minimise the initial investment costs and also to maximise productivity at the same time enjoy significant reductions in day-to-day operating costs and then as demand builds up, the ability to add further modules to the line.

Stemas have recently taken two orders for their fully automatic lines, one in the UK and one in the Republic of Ireland, one will be delivered by the end of 2021 and the second within the first six months of 2022 as well as these two recent firm orders there has been a major groundswell of interest from several major UK door manufacturers with projects reaching “Critical Mass” and orders are expected to be placed for two, possibly three full lines before the end of the year.

Tailor made solutions

Although the PERFECT DOOR systems are of very well proven technology, developed over many years each system is designed to the customers exacting requirements to suit their specific manufacturing needs as opposed to the more traditional ‘off the shelf’ CNC Router offerings where, more often than not, the customer always has to make a compromise, he can never truly have what suits his exact needs. In essence with STEMAS, the attitude towards producing special execution CNC routing solutions is a normal day to day activity, the process of customising the machine line configuration prior to manufacturing is a key element to the success of the PERFECT DOOR systems, it is 100% co-operation with the client, their input is highly valued.

Different types of door hardware really do require dedicated working units, so as to achieve the high through feed speed whilst maintaining dimensional accuracy and quality of machining.

Stemas PERFECT-DOOR can work with almost every kind of hinge on the market as well as the standard or tailored lock systems, with the advent of ‘SECURE by DESIGN’ more specialist hardware is required and again STEMAS provide the systems to accommodate such.

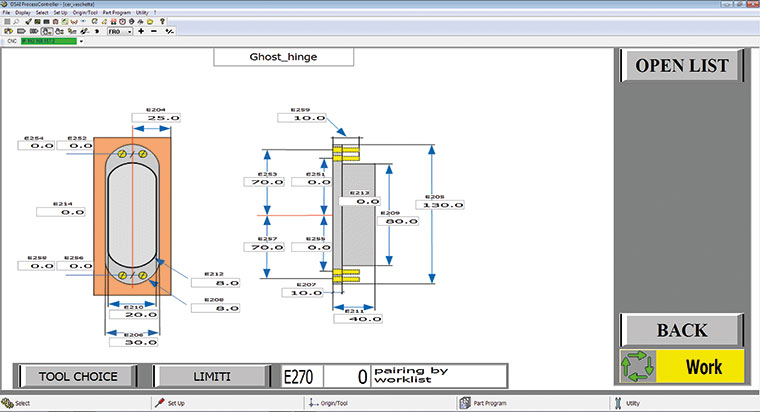

Unlike many providers of door processing machinery STEMAS have their own ‘Software House’ with some of the top software engineers in Italy, STEMAS are justifiably proud of their unique systems; The internal software department makes sure that the user interface displays on the touch screen are a parametric graphic which grants an easy programming of any change in the machining of the hardware locations, in essence extremely user friendly and again bespoke to the client’s needs, no short-cuts are made in this regard

State of the Art

As stated earlier the PERFECT DOOR system is a modular concept and can be built up in stages as the client’s work and orders increase, ranging from semi-automatic to fully autonomous self-running systems only requiring basic supervision and not needing an operator in permanent attendance.

There are two basic ‘units’ one can consider as a start point, the ‘Stage One’ and the ‘Full Line’ even these two basic systems can be enhanced greatly either straightaway and/or step-by step.

The stage-one PERFECT-DOOR comes as a single working station, able to perform a basic door process every 45 seconds*; Basically, the milling of three/four hinges with pilot holes on one side, plus the milling of the lock and strike-plate with pilot holes, keyhole and handle seats on the other side.

It is the natural evolution of the traditional CNC centre, combining the flexibility of the various working processes with the possibility to work on two sides and the top router simultaneously, to boost the overall productivity.

These lines come with a Portal Vacuum Bridge for the automatic feeding and stacking of the doors; lifting the doors from the stack which is normally placed on pallets and/or roller tracking; the stacking is the same operation except in reverse, the line is effectively autonomous, and requires no real manual intervention, as long as the in/outfeed of material is taken care of, most PERFECT DOOR systems run from motorised roller tracking on the infeed and outfeed and there is no real no for the line to stop unless it runs out of doors to process.

These systems also have certain automatic ‘dimensional quality’ check via the numerical control which can dialogue (Bar/Q codes) with the internal servers to extract the working data after the automatic reading of a barcode or RFID, as well as simply import a .csv working list.

Besides the most common operation for interior doors, the top router with tool magazine up to 24 positions, is able to execute special operations such as the milling of the automatic door closer, ventilation holes or the bottom guillotine seats.

The through feed system also works in conjunction with integral vacuum cups, which raise and secure the door above the feeding belts, the whole surface is free for a 6-side processing, including the squaring and the opening for glass or panels as required by the client.

PERFECT-DOOR-HP, is in essence a second routing/work station added to the stage one module ,the two working stations divide the longest operations between them and ensure a productivity up to a completed door each 20 seconds.

This advanced solution, is suitable to process wooden and/or metal doors, it is now reputed to be the ‘go to’ choice of the biggest door producers in the world.

It can come as a turn-key solution or also be the result of a future upgrade of the single station, helping the customers in a two-step process of growing production.

The layout of the line can be also designed with an additional working station able to insert the hardware. Either rotative or vertical magazines for hinges or locks feed 3-cnc-axis units able to insert the elements and screws with brushless motors.

It is also very common for these full lines to have ‘barrel turners’ between the two working stations to further increase operational flexibility

Component insertion

In recent years there has been a growing demand within the door process industry for the automatic insertion of hardware, including the UK, this is where STEMAS really does lead the market in cost effective systems, hinge insertion with screw fixing, lock insertion with screw fixing

The layout of the line can be also designed with an additional working station able to insert the hardware utilising either rotative or vertical magazines for hinges or locks feed three CNC axis units able to insert the elements and screw with brushless motors.

A fundamental feature of Stemas commercial strategy is the long-term relationship with its customer. Whoever owns a Stemas machine is a repetitive purchaser; many door factories can be a display of up to 30 Stemas machines, being proof of the high reliability of the installations and the after-sale service.

For further information please visit our websites or email for more details.

[email protected]

www.stemas.it

* Basic door processing is deemed as machining 3-4 hinge recesses, hinge pilot holes, strike plate, lock slot, handle hole and keyhole