Lawcris operates out of four units, totaling 200,000ft2. Manufacturing is split over two of these sites; the first containing facilities for cut, edged and machined components – favourably named Creative CNC – and the second housing the company’s bonding facilities. Over the last couple of years, close to a £1m has been invested into these services, responding to customer demand by upgrading its equipment, machinery and infrastructure.

Lawcris has gained a remarkable reputation as one of the most successful independent panel product companies, offering melamine boards, laminates, worktops, acrylics, veneers, solid surfaces, raw boards and much more to the UK market. Having this stock in house has allowed its services to run far more effectively with no delays in getting the boards in the first place.

However, providing a speedy service is only part of the story – achieving optimum efficiency is not about individual components. Overall, success has come from how its services work together to deliver exactly what the customer needs.

Bonded boards

Lawcris is a key supplier of bespoke laminated products and has the capacity to output large quantities of bonded sheets, approximately 60,000 a year. The success of this service is not reliant solely on the high-quality pressing, it is so much more than that. Lawcris excels with achieving the seamless first-class experience from beginning to finish.

Bringing together the ease of choosing a laminate and core board on Lawcris’ award winning website, to rapid picking of the chosen products from a warehouse holding over £4m of stock, to the selection in press sizes; 8 x 4ft (2440 x 1220mm), 10 x 4ft (3050 x 1220mm), 10 x 5ft (3050 x 1525mm), 12 x 5ft (3660 x 1525mm) to the fast turn-a-round where the bonded boards are manufactured and controlled using the very latest technology and extensive experience – no stone is left unturned.

Finally, a delivery service from their 40+ fleet and ensuring the customer gets the aftersales support they need, it is clear that when it comes to laminate fabrication, Lawcris offers an unrivalled service that is hard to match.

Creative CNC

Lawcris has one of the most comprehensive range of decorative boards in the UK with over 1000 designs including colours, woodgrains, patterns and metals. Further to this, Lawcris stock over 3000 combinations of these designs with different sizes, finishes, textures, cores and further choices depending on whether there is a requirement for moisture-resistant or fire-resistant standards. It only makes sense that they complement this impressive range of stocked materials with a cut, edge and machined service – Creative CNC, which all follows on nicely from the bonded boards department.

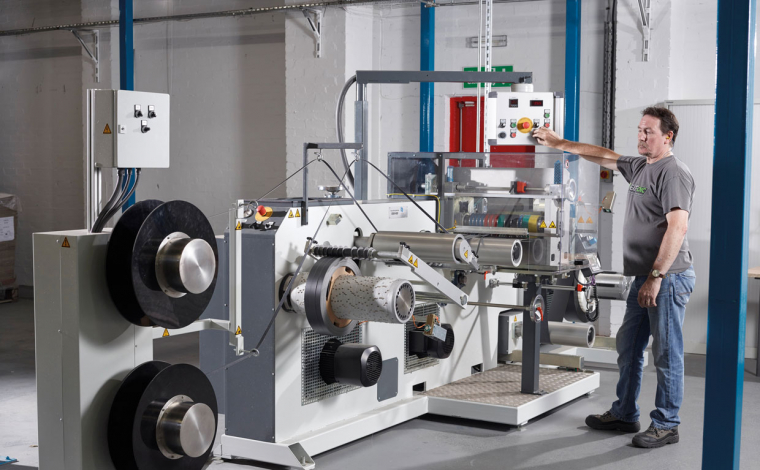

35 years’ experience has built an impressive database of customers including shop fitters, exhibition, joinery, kitchen and furniture manufacturers. A constant program of investment ensures Creative CNC offers the highest quality of service with an impressive fit-for-purpose facility and the latest technology including an epic portfolio of up to date machinery including beams saws, edge slitting and edge banding machinery, CNC’s, panel saws and spindle moulders.

The most recent investment has pushed the accuracy and speed of the CNC department to new realms, halving the production time and getting projects out much sooner to their customers.

Stuart Hall, general manager of Creative CNC, says: “New equipment and facilities have significantly improved the speed of our manufacturing process. When producing components, efficiency is everything. Maximising the yield from each board and minimising waste is massively important, that’s something that everyone at Lawcris understands.

“With the recent purchase of two HPL 500 Holzma beam saws, we have enhanced the quality of cut and our consistent saw capabilities allows us to effectively offer even better service, especially in a market that expects reliable excellence, best prices and delivery yesterday!

“Speed and autonomy are definitely the key words associated with our incredibly efficient high-tech beam saws. The saw blade projection of 150mm enables us to cut up to seven sheets of 18mm MDF at once with the saw carriage speed of up to 130m/min, producing super quick cutting times.

“Boards as thin as 6mm can be loaded automatically from the rear of the machine and the programmed turning device for headcuts reduces panel handling and preparation time for cutting. The addition of a labelling machine, which is hugely popular with our customers, means every component we supply can be labelled, if required.”

Another recent addition is the company’s new edgeband slitting machine, which allows Lawcris to keep up with the increased volume of tailored widths, a popular demand the company is currently seeing in the market.

Stuart goes on to say: “The new slitter performs effortlessly with fast slitting speeds and easily adapts to meet bespoke widths of up to 100mm. This has doubled our edging portfolio to over 1000 items, allowing us to add a number of new ABS options in widths 22, 23, 28, 29, 33, 45 and 54mm. All these additional widths can be bought in the popular 75m rolls.”

Ian Matthews, Lawcris director says: “We understand that we are in a great position. For a lot of businesses, purchasing new machinery is a large financial decision. There are so many things to consider, such as how much the new machine will be used, running costs, what extra output and capacity it will create. Sometimes it simply isn’t viable.

“This is where we can help businesses effectively outsource their projects with repeatable high-quality panel based components. Our purchasing power within the panel products industry and efficiency in our machinery allows us to create very competitive quotes for the same work some businesses might do in house.

“Using older machinery may not be as proficient, fast or cost effective and could potentially damage relationships with their own customers. We see ourselves as an extra arm to those businesses and can support them to cut production times for those who need bonded boards or custom made, sized, drilled and edged components.

Lawcris’ vast success has been achieved through their services faultlessly working together to deliver exactly what the customer needs. With everything under one roof and access to its huge product portfolio clearly displayed on the company’s user-friendly website, Lawcris has set the bar in terms of reliability, speed, cost effectiveness and first-class quality.