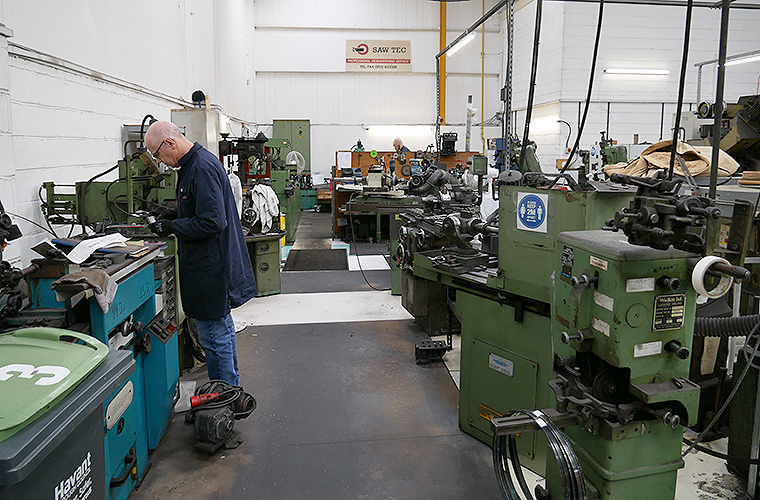

Brian and Valerie Bourne started Saw Tec in 1989 wanting to provide a re-sharpening service to the wood and metal working industries. The company’s humble beginnings was a tin shed down a farmyard track, with machinery that Brian had either purchased second-hand or refurbished to help make their dream a reality.

Over the decades since, the Hampshire based Saw Tec has become an established and dependable company, going from strength to strength, investing in state-of-the-art CNC grinding machinery, bigger premises and earning itself an even bigger reputation in the South for providing a high standard of service.

Saw Tec MD, Brian Bourne

“Our dedicated staff maintain progressive relationships with our customers,” explains Brian. “We work directly with our clients to provide expert tooling knowledge to a diverse collection of customers, including joinery companies, kitchen manufacturers, fine furnituremakers, fire door production lines and picture-framing firms. To maintain quality control, every re-sharpening section has its own dedicated technician. Therefore, each department is solely product focused, enabling the individual grinding needs for every tool that comes through the door.”

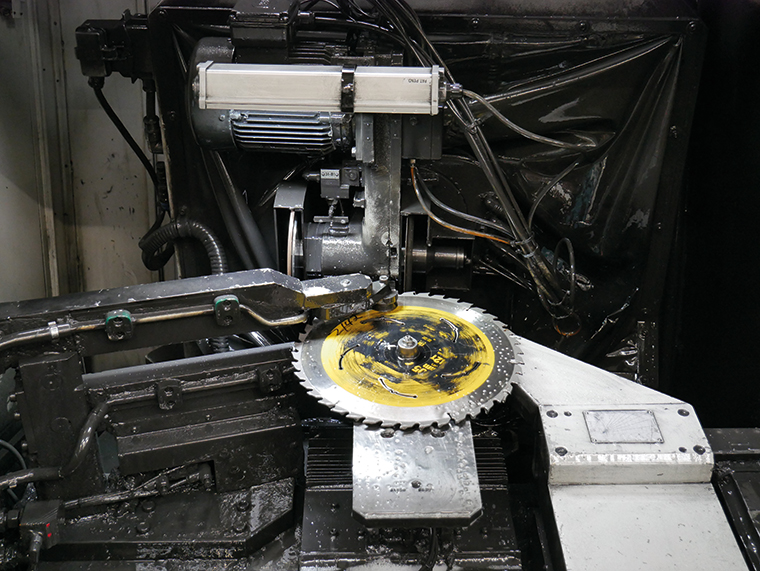

Saw Tec’s advanced CNC machinery from Walter, above, and Vollmer, below

Saw Tec has four main re-sharpening departments, which take up the majority of the footprint of its modern workshop and showroom. Sawing technicians Paul Grover and Paul Langler use advanced CNC machinery from Walter and Vollmer, while the company’s saw doctors Glyn Cherrett and John Parsley also use classic old-fashioned machine technology for the more traditional tooling.

“We only use oil-based coolants in all our grinding,” explains Brian. “This not only gives a cleaner finish, but prolongs the life of the tool. The vast majority of tooling that comes to us is cleaned, inspected, serviced and returned within one week. Our collection and delivery area covers eight counties, with customers from further afield regularly shipping blades to us.

“Bespoke tooling is something we take great pride in. In the last two years alone, we have included more than over thirty new tools to our range. Engaging with the customer’s needs, designing and manufacturing either TCT blades, spiral solid carbide routers, PCD tooling or spindle cutters is of great importance to us. We understand and enjoy the challenge for exact specifications – whether that’s working from a CAD drawing, from a sample of a tool that needs modifying, or by phone. Our underlying relationship of trust with our customers is most prominent when a specific tool can be spoken about and initially designed over the phone.”

“Thirty years of trading has shown us how the industry has evolved” says Brian “and we have successfully adapted to meet those needs. Customers in today’s market are looking for the full package when it comes to cutting requirements. We aim to offer a comprehensive service to fill that demand.” A large part of this is the expansion of their team of mechanical and electrical engineers, who are able to carry out breakdown repairs, provide preventative maintenance checks and machine installations.

During the lockdowns, Saw Tec were relied upon by customers contracted to support the NHS. With minimal staff both in the workshop and drivers making deliveries, they assisted sign makers, refrigeration companies, leaflet/banner printers and PPE manufacturers to name a few. Sarah comments “To be part of such a vast ‘background network’ in support of the NHS was a privilege”.

Despite last year, Saw Tec has emerged a stronger company as Brian explains “Once the lockdowns eased, supplementary grinding and machinery training was given to our sawing technicians and doctors to achieve additional technical abilities. Skill sets across all departments were refreshed and optimised.

“One of the biggest reviews undertaken in 2020 was an improvement of our collection and delivery service. By simplifying the routes we have been able to visit more customers cost-effectively on a weekly basis.

“Coupled with a determination not to let our customers down and our own resilience, surviving the challenges of 2020 has been an incredible effort achieved by every single member of staff.” Brian says, “The willingness to adapt and survive has brought us to where we are today and I am very proud of my team members.” Going forward, Saw Tec will continue to invest with more machinery, for both the workshop and machine showroom and will employ additional staff to help with increasing demand.

Saw Tec director, Sarah Taylor

The friendly and experienced office team are at hand to help with a variety of enquiries as Sarah explains “Our customer’s cutting requirements is a parameter that is constantly changing and sometimes these modifications are critical to timeframe. Recently, an urgent alteration to a routine door manufacturing design was required. Working from drawings, a new cutter was designed within 24 hours. Following its successful trial, new solid carbide tools were produced within a week allowing our customer to meet his original deadline.”

Saw Tec woodworking machinery manager, David Stead

Saw Tec’s Machinery Manager, David, is also keen to help clients solve problems. “Waste is an issue all manufacturers have and when on site with a customer, I noticed large piles of waste being thrown into skips. I approached the subject of waste with them and asked how often it was being collected for disposal and its composition. They were disposing of off cuts, pallets, dust, chippings etc and were spending thousands of pounds per year on waste disposal. Utilising such waste hadn’t even been considered before I spoke with them about it,” explains David.

“I suggested that with the investment of a shredder, briquetter and wood burner that they could manage all waste on site and do away with the skips. The briquettes could either be sold or burnt onsite with the heat vented externally or used to heat the workshop. This was a solution that could offer a return on investment (ROI) in three years and sustain reduced heating bills for the long term.

“Specialist engineers delivered and installed the machinery with the project overseen by Saw Tec and the benefits were seen within weeks. The most immediate benefit was seen in the cash flow not paying for skip hire.”

Another way of helping customers is to alleviate any concerns regarding the supply of new goods. “In the aftermath of Brexit, a lot of our suppliers have struggled to import from the EU,” comments Brian. “Delays at customs and general availability of raw materials are the most prominent issues we are all dealing with at the present time – we are constantly reviewing the situation to ensure plenty of stock of our most popular items.

“We hold a healthy supply of panel saws and scorers, Tersa knives, carbide bar, HSS blades, lubricants and other products, whilst keeping in contact with suppliers to monitor availability. We aim to supply standard items within two working days if it cannot be delivered on one of our van routes.”

In addition to the impressive saw blade and sharpening side to its business, Saw Tec has a long-served reputation for new and used woodworking machinery sales, installation, training, after-sales service, repairs and spare parts across the south. Their extensive network of suppliers for machinery and tooling includes AES, Altendorf, Genesis, Kundig, NLS, Stehle, Swedex, Trend, Titman and Whitehill.

The company’s busy showroom has a good stock of new machinery consisting of a ProTec CNC nesting machine, Altendorf panel saw, Genisis edgebander and panel saw, Kundig edge sander and SAF extractors. They also have used wide belt sanders, planers and thicknessers. All machines are available to demonstrate.

For further details, contact Saw Tec about re-sharpening, servicing or machine needs.

02380 653329

[email protected]

www.sawtec.co.uk