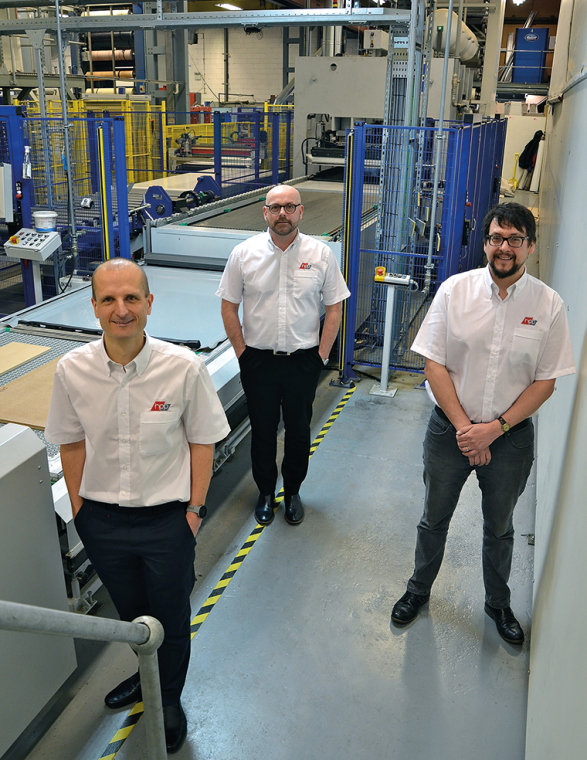

From left: Dan Mounsey, Keith Wardrope Gareth Evans and Andrew Evans

.

Fitted furniture components manufacturer and distributor Hill’s Panel Products (HPP) is marking its 30th anniversary, as the sector, wider economy and society at large continues adapting to the ‘new normal’ post-lockdown life.

HPP, which is a doors, boards and fittings specialist, is celebrating its history and growth with some anniversary publicity and activities this year. But ongoing Covid safety precautions mean that physical events, such as staff celebrations to mark the anniversary, are being pushed back to in 2022, if circumstances allow. (Similar to the recently rescheduled Euro 2020 football championships).

HPP was founded in 1991 in a single industrial unit in Oldham, Greater Manchester, measuring 11,000 sq ft unit. Over the years, its head office site has grown to 11 units measuring over 250,000 sq ft – there is now also has a second UK distribution centre in Sheffield and operates nationally.

Today, the company has over 2000 trade customers and supplies over 7000 products including its own brands of doors and cabinet components, full and processed sheet materials, vinyl-wrapped furniture doors and furniture fittings. Its own brands include Avanti doors, Glide sliding doors, and Aspect and Aspire kitchens and bedrooms. It also supplies products by other UK and European brands including Egger, Blum and Kronospan.

In recent years, its turnover has risen to over £34m and it currently employs just under 200 people. It undertook a major investment programme in manufacturing equipment and warehousing in recent years – just before the pandemic began in 2020.

The company is headed by brothers Martin and Stephen Hill and managing director, Keith Wardrope. In this anniversary year, three new directors have joined the board, representing a new generation of future leaders. Other appointments have been made right across the business and the company is also investing in staff training and development across all departments.

Investment and growth before the pandemic

Between 2017 and 2019, HPP grew on multiple fronts and had a multi-million-pound investment programme. Overall sales grew by 16% in 2018, on top of 15% previously. Door sales rose by 30% and 11 new staff were trained for manufacturing in 2019, the year its second door production line was opened.

The £3m second production line increased the company’s capacity to manufacture bespoke vinyl-wrapped doors for trade customers across the UK and Ireland. It enabled increased output from 30,000 to 45,000 units per month in the short term. In the longer term, output can rise to 50,000 per month or more.

The new line contains automated routing, cleaning, glue-spraying and vinyl-wrapping machinery supplied by Wemhoner and Sittex. The Italian-made Sittex equipment was the first in the UK.

Speaking about the increased manufacturing capacity, MD Keith Wardrope said: “HPP is now one of the leading vinyl-wrapped doors and kitchen and bedroom component manufacturers in the UK. All our doors are manufactured to bespoke orders, with options on shapes, sizes, routing patterns, hinges and decors. The new production line manufactures doors across 40 styles and 70 colours, offering 2800 possible combinations. Seventy or 80% of our vinyl-wrapped doors can now be manufactured on the second production line while our first production line will focus on more intricate orders.”

He added: “The new production line shows the continuing importance of the company’s agenda of moving forward through automation while also securing jobs for people. Some may worry that automation lead to job losses. However, HPP is using automation to secure jobs and to grow for the future.

“Automation allows us to be competitive in the door manufacturing market by making production easier and more accurate. And because we have been getting busier over the past few years, we also needed to recruit extra staff.

“We must emphasise that our employees have contributed hugely to our success over the years and we want to reflect this in our 30th anniversary activities. We have a number of long-serving staff with really strong skills and experience. We are also attracting good young recruits across a range of roles and departments, which promises a great future for our company and furniture manufacturing in the UK.”

Other investment over recent years has included a new £2.5m 19,000 sq ft warehouse to support the expansion of manufacturing. The building is the biggest free-standing warehouse at the company’s HQ in Oldham. The triple-fronted warehouse store worktops and panel products. Its construction freed-up other space for the second door production line. It was the fifth warehouse to be built at the Oldham base.

In addition to equipment and facilities, HPP has increased its value-added services through bespoke offers for customers and partnerships with other brands such as Egger, Kronospan and Blum.

Examples include a customer order service to turn advanced sheet materials into doors and cut-to-specification orders for doors and panels with wide décor choice and optimised use of sheet materials, reducing waste.

HPP also launched a new service offering pre-assembled Blum drawers. Flat pack Blum components are assembled at HPP then delivered in boxes directly to installers, offering ultra-convenience to the trade customer. This service is being extended and HPP wants to increase its trade customer services across all its activities.

The lockdown and new normal

Although full national lockdowns have been lifted (at time of writing in), the pandemic’s impact continues to be felt and evolve, creating new challenges for businesses of all types and making the future difficult to predict.

However, HPP says a priority is to assist the fitted furniture industry’s recovery from the impact of the lockdowns and to transition to the new normal.

The company has developed a number of support offerings for retail showrooms along with digital resources to help the kitchen, bedroom and bathroom (KBB) fitted furniture sector in the new environment.

When the first national lockdown of 2020 loomed, HPP had to act swiftly like other businesses. After discussions with staff, both sites in Greater Manchester and Sheffield were closed within two days In March 2020.

But it was also very conscious of customers’ needs too during the ensuing lockdown. In the early days, the company contacted trade customers with an email survey and asked if they needed any specific help. A click-and-collect service was offered to help smaller installers finish jobs they had been working on, such as fitting kitchens or bedrooms inside empty houses.

Later in the spring of 2020, HPP opened its warehouses very minimally to receive some large deliveries then slowly reopened manufacturing, despatch and office functions on a restricted scale. Once new Covid safety measures were enacted, a very small group of staff returned to work in mid-May 2020.

The lockdown era was not without pain. Keith recalled: “Sadly, we had to make some redundancies but those were fewer than we feared. Some staff were subsequently re-employed, which was great. We had to adapt to the impact of the pandemic and tried to respond positively to diverse new challenges and opportunities.

“We gradually became fully operational and demand became quite strong, with the boom in home improvements with home working, home schooling and other big changes of 2020. We have seen signs of growing economic confidence but it’s a complex picture with different factors are at play. However, many people are still spending considerable time at home and investing in property, one way

or another.

“Likewise, commercial property is seeing changes as a result of changed working, commuting and leisure patterns. We are seeing re-purposed commercial spaces, more mixed-use of office and retail properties, and more flexible planning regulations. All these developments and trends will feed into architecture, interior design, interior specification, furniture and fittings.”

Showroom packages and online support

To support the fitted furniture sector’s recovery and development, HPP is launching physical product packages for showrooms and enhanced online resources.

Dan Mounsey, who became HPP’s director of marketing and business development this year, explained: “We believe our retail showroom package is quite a unique offer, due to us being the only company that can cover all these bases. We aim to offer free HPP kitchen and bedroom displays to retail showrooms and a contribution towards the fitting cost. Our plan is for our packages to cover worktops, kitchen and bedroom doors, Blum hinges, HPP’s Blum ready-made drawer boxes, door handles, lighting, wire-work and bins.

“We’ll also assist with showroom point-of-sale aids, handle display boards, our Unique Choice kitchen and bedroom brochures, discounts on showroom accessories and the Easycab range, and access to marketing and merchandising aids.”

New online resources for trade customers include an Egger Inspiration Centre on HPP’s website. Dan said: “We are an Egger Diamond Distributor and have enjoyed a great relationship with Egger for many years. The Inspiration Centre brings together all Egger’s digital resources and tools in one location including enhanced 3D visuals which capture advanced décors. The new Egger Decorative Collection, door ranges with Egger decors and Egger worktops are highlighted too. Physical samples can also be ordered by trade customers.”

Sustainability is increasingly important for the furniture industry and in consumers’ purchasing decisions, says HPP. The Egger worktops are PEFC-certified and use

renewable material.

The 38mm worktops can all be recycled and the range has FIRA Gold Award for product testing and quality. By highlighting such features and measures, it believes furniture showrooms and installers can help to distinguish themselves in the market, especially to younger, environmentally aware consumers.

In keeping with its promotion of the sustainability agenda in furniture, timber trades and forestry, HPP has been a sustainability partner at the annual KBB Design Awards and supported a range of tree planting and environmental programmes in the UK and overseas. Programmes include tree planting in Manchester schools and the Royal Horticultural Society’s new 156-acre Garden Bridgewater in Salford, and sustainability projects in Africa and India.

New directors, appointments and training

In addition to Dan becoming a director this year, HPP has appointed Andrew Evans and Gareth Evans as IT director and sales director respectively.

Andrew, 45, joined HPP in 2004. His first role was continuous improvement manager. Later he became IT systems manager which diversified to include company data management systems including business Intelligence. He then progressed to IT manager with extra responsibility for hardware, infrastructure and enterprise resource planning (ERP).

He said: “Becoming a director at HPP is a great step forward for me. I want to add extra weight to all areas of the business and to use my skills and those of the IT Department team to advance the company.”

From left: Dan, Gareth and Andy

Gareth Evans, also 45, first started at HPP aged 17 in sales. He said the opportunity to work across many different departments was invaluable for his knowledge and development.

“I’ve spent all my career in the KBB sector, including a spell with Slumberland. I’ve now been with HPP for 20 years and seen a lot of positive change. I’m really pleased to become a director with Dan and Andrew. Our combined knowledge can help ensure continued success for HPP,” he says.

Also, this year, Gary Kinder (above) has joined the company as purchasing manager. The 53-year-old has extensive industry experience and his CV includes roles with Eurospace Furniture, Symphony, Richmond Cabinets and JT Ellis.

In other staff developments, HPP is investing in workforce development with 17 staff members joining an ILM Level 2 qualification course for leadership and team skills. The qualification is designed to help individual staff improve their performance as team members and assist their transition from working in a team to leading a team. It also helps practising team leaders to be more effective and confident in their work. The aim being to enhance the company’s operations at all levels in order to improve efficiency and service to trade customers.

Scott Frost

Dan said: “Our business is committed to skills and training right across all departments and at all levels. It’s great to see 17 staff involved with this Level 2 programme.

“It will enhance our operations in many ways by giving staff more insight, skills and understanding of business needs and issues. It’ll boost both individual and team communications, direction, productivity, planning, problem-solving and development. We are also looking to progress staff onto the next Level 3, building on this.”

Two groups of staff have already taken part in the training sessions held at Oldham Events Centre at Oldham Athletic FC.

It is also helping to address the industry’s growing skills gap by providing work, training and mentoring opportunities for six young people at its Oldham HQ and second UK distribution centre in Sheffield, under the Government’s Kickstart programme. This provides funding to support placements for 16 to 24-year-olds who are at risk of unemployment but keen to gain experience, skills and an income.

HPP has a history of supporting young people. This includes speaking at careers fairs to raise awareness of the furniture industry, supporting an Oldham youth centre and hosting educational activities.

In summary, HPP is very busy on all fronts as it looks to the post-lockdown future. Hopefully, there will be some time for it to collectively celebrate its 30th anniversary safely in coming months, as it and other furniture businesses adapt to the ‘new normal’.

0161 628 1147

www.hpponline.co.uk