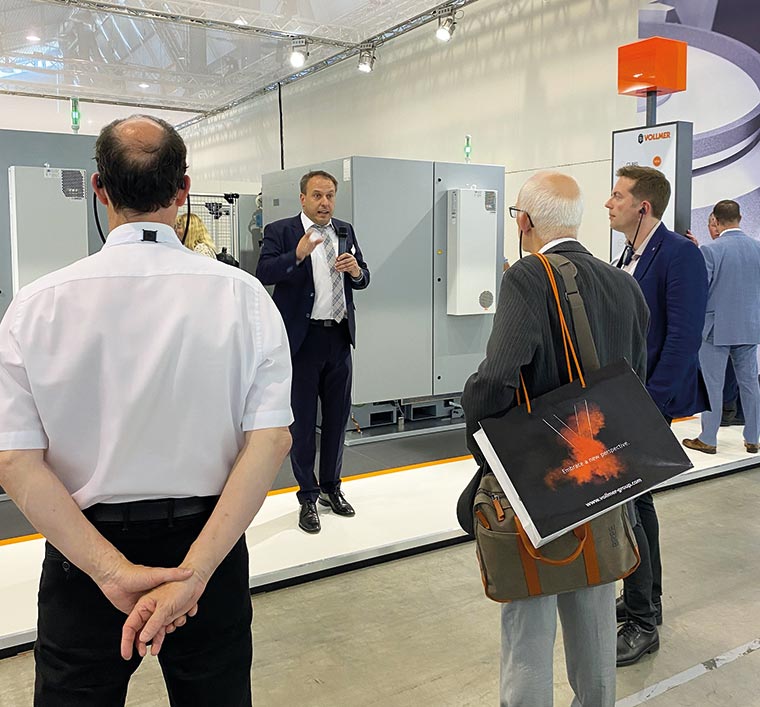

Thomas Wenger with the new Vollmer CS860 machine at GrindingHub 2022

.

Working for Vollmer for 24 years and spending over 14 years in product management, Thomas Wenger has incredible industry experience in the circular saw marketplace. With the new CSF860 side grinding machine and the CS860 face and top grinding machine both making their worldwide exhibition premiere at the GrindingHub exhibition in May, we speak to Thomas about the arrival of the two new machines.

Discussing the concept behind the two new machines that will supersede the CHD 270 and CHF 270 saw blade processing machines, Thomas says: “The CHD and CHF machines were based on a completely different construction to our new technology. The CHF side grinding machine was designed in 2000 and the CHD face and top grinding machine was designed in 2004-05 – we continually evolved these machines, but we reached the limit of what could be achieved with the existing construction and this was reflected in the machines at the end. Now, with new drives and software technology on a new foundation – we can add new features for our customers.”

“We identified our development goals and we started to design the CS and CSF machines. So, the base, the housing and many other elements are completely different to before, but components that have proven their stability and accuracy over many years remain. We have designed both new machines with the same kinematics, housing, structure and polymer concrete base, so we can have a modular foundation. This makes it easier for us internally to streamline production and reduce lead times. It also makes the machine easier for the operator to handle as there is greater synergy between the CS and CSF machines. This creates uniformity with regard to loading, setting-up, the view and ergonomics and also the programming.”

“This uniformity of technology was our target, adopting the same CNC, operating philosophy and also the latest drive technology. In the past, we used some servo motors with standard synchronous motors. Now, all motors, grinding spindles and axes are servo driven. We have seven motors on the CSF side grinder and eight on the CS face and top grinder, this includes linear CNC axes plus three CNC grinding spindles on the face/topper and two CNC grinding spindles on the side grinder. The servo-driven grinding spindles provide a higher quality saw blade and we can now conduct different in-feed and cutting speed rates on each tooth. This improves the surface quality of the cutting edge and brings more flexibility into the grinding process. Customers can now do whatever they wish.”

Expanding on the servo motors, Thomas says: “Previously, standard motors had power and encoder cables, by evolving to the OCT (one cable technology) hyperface technology there is just one cable. This means there are fewer cables and switches, reduced power consumption and it is easier to change a single cable – something that reduces the future service costs for the customer.”

Thomas Wenger presenting the two new machines to the press at the GrindingHub Show

New features that fulfil the four foundation blocks

With any new concept, the experts at Vollmer aim to achieve four key delivery parameters for customers. These are increased flexibility, productivity, reliability and quality. Alluding to this, Thomas adds: “We met the goals by creating more stable processes in the new machines to provide better grinding results at the cutting edge. This was the fundamental reason for the new CNC control, motors, new features for oscillation, grinding and cutting speeds.”

“Looking at flexibility, one important thing is the integration of an additional axis, the R2 axis. This cross-axis at the saw carrier makes it possible to grind saws with a flange. Flexibility was previously limited because saws were manually set. Now, this is completely flexible as you can mix saws with different flange heights and even mix saws with and without flanges.”

“Flange saws are very prominent in the wood industry and this will make it much more flexible to accept different types of saw blades. Previously, a customer would need 10-15 minutes to undertake this reset/change-up. Of course, some customers only undertake this saw type change once a day, but others repeat this a few times a day. It’s now done immediately, saving the customer time.”

“We also have a new ‘centre brake’ feature. In the past, we would put the saw carrier on the machine and the saw blade would rotate on the flange. When processing coated or strobe saw blades, the carrier could leave scratches on the blade - so we created a carrier that rotates with the blade. In the end, there is a centre brake and clamping plate on the gullet that opens when we push the tooth to the next grinding position. If it is left closed, there will be scratches in the gullet area, if you open the clamp and push the next tooth - you need to hold the saw blade somewhere. This is why we use the rotating flange together with the centre brake, so we can open the clamp and push the tooth to the next position. This eliminates scratches at the centre or around the gullet area at the end of the process.”

The major advantages of software

The four pillars of flexibility, productivity, reliability and quality are often interwoven in the very DNA of machines – overlapping with each other. With the new CS and CSF machines, Vollmer has pushed the boundaries of software technology on all fronts. As Thomas states: “On the CHD machine, the software automatically recognised the end point of grinding, and that was it. We have evolved this to increase output by up to 20%.”

“The new optional software takes the calculation work away from the operator. At present, the operator measures the grinding length on the face, top and chamfers. If the customer has trapezoid geometries, the straight part of the tip can be longer than the chamfer, which means some faces may need more grinding than others. The new software calculates where the customer starts and finishes the grinding pass - doing everything automatically. The customer no longer has to measure the difference between the flat surface and chamfer. The in-process cycle reduces non-cutting times. For example, a tip with a 15mm surface area on the top face may only require 12mm of grinding on the chamfer. Our software automatically calculates this, so 3mm of ‘air-cutting’ per tooth is eliminated.”

“This patented technology reduces production times. As an example, if you eliminate 3mm of air cutting on a 60 tooth saw blade, that is 180mm of air cutting. If you are grinding at 4mm/sec that is a saving of 45 seconds on a single blade.”

Emphasising the software evolution with the new CS machine, Thomas says: “In addition, the customer now has less data to input. There are just two main pages and this has always been our strength, but we have now simplified this furtherby integrating more measurement functionality. One page for the face and another for the top grinding - and the customer can activate particular features just by entering a one or a zero. Previously, the operator would measure each parameter and programming was a combination of having the saw blade on the left-hand and the programming screen on the right side. Vollmer only used to measure the hook angle, but now we also measure the clearance and bevel angle. Once the operator activates the feature, he no longer measures – just inputs basic data like tooth shape, number of teeth – and that is it. This eliminates much of the ‘pre-measuring process’ that can be two-to-three minutes per blade.”

“Nowadays, we are increasingly calculating production costs per square metre, especially in saw service centres that have limited space. To free up capacity without building a new hall or facility, this new technology will reduce the production cost per square metre for customers, as the machines can produce more blades per day.”

Vollmer’s Thomas Wenger Introducing the two new machines

Software for the Sawmill

“One cost reduction per square metre contributor is the new pocket grinding feature. The guys in the sawmill industry are re-tipping saws and using the saw body 2, 3 or 4 times. These companies heat off the old tips and before brazing-on new tips, they manually regrind the pocket seat – a labour intensive job. We’ve added this is a fully automated process. So, if customers have taken the teeth off the saw body, it can be added to the stack and the pocket will be reground. In the high-end metal industry, pocket seat grinding has to be very precise. They may be milling or laser cutting the saw body to tolerances of +/-0.1 or 0.2mm, this is too high for manufacturers producing metal cutting saw blades – we can now automate to much higher precision levels.”

“From a flexibility perspective, we also added a multi-surface program where the customer can input up to 30 lines. This allows the user to program three multi-surfaces, and the multi-surfaces can be added to one facet or 90. We have also extended the diameter range to 860mm from 840mm.”

Bridging the skills gap

The evolution of software is also helping Vollmer to bridge the skills gap for its customers. As Thomas continues: “If you look at our VPulse or Vgrind, we have a different user interface that is more well-known in 5-axis CNC grinding, but operators in that field are different to the sawmill industry. Our software explains everything with pictures, simplifying the process for operators with no background knowledge of saw blades. The two pages of content that an operator has to complete, are the same as before - but data input is significantly less. We always aim to increase automation, as our customers have a challenge with staff skill levels. Once upon a time, a saw shop would have many staff that could programme machines. Now, companies with 30 to 40 staff may only have one or two employees that can do this. This is a challenge we are undertaking to support our customers.”

Integrating software and Industry 4.0

Expanding upon customer support: “We have also incorporated Industry 4.0 technology with our software. Now, if an end-user has quality concerns with their saws, our customer can undertake a final inspection before dispatch. When a saw is complete, a measuring sequence can be applied to one tooth or all teeth on the blade. Our customer can select their measurement parameters. This process creates an XML file for quality and traceability to ensure each saw is 100% correct. Previously, saw manufacturers and service shops used manual measuring equipment and inspected every fifth or tenth saw blade for conformity - and then recorded the data. Now, a fully automated sequence can be integrated to save considerable time.”

Precision and quality

With Thomas already emphasising how software is reducing data input requirements, ‘air-cutting’ times and manual measuring processes – the software cannot undertake such tasks without the supporting hardware. And here, Thomas acknowledges the ingenuity of the new measuring technology: “The stable production processes are derived from three measuring devices. First, we have the Renishaw MP250 measuring probe repeatable to 1µm. It has high-end 3D precision unnecessary on machine tools that only require single point contact. We use the Renishaw MP250, as its spherical system provides remarkable accuracy regardless of contact point direction and we need this as our face and top grinders, measure all around the tooth.”

“The second system is the brand new measuring cube for the grinding wheels. It has an absolute fixed point and it gives absolute knowledge of the grinding wheel position. If there is a temperature fluctuation in the machine or spindle, this fixed point will compensate for all other parameters. It is very stable and fast. We can measure the grinding wheels whilst the machine changes the saw blades. In the past, it was necessary to compensate the grinding wheel by measuring the tooth - this was unproductive time. Integrating this process increases grinding stability whilst reducing unproductive time.”

“This grinding wheel measurement is pre-programmable, but the manufacturer generally knows they need to recalibrate the wheel every 5 or 10 saw blades. The customer can define the measuring point, whether it be by the number of teeth or saw blades processed. Furthermore, the customer is not losing production time – a concern in the past. As an example, the wheel measuring process takes 20 to 25 seconds and it can be undertaken simultaneously with the saw blade changeover takes 25 to 30 seconds when using a double gripper system or roughly 50 seconds with the single gripper system. This effectively enables every saw blade to be measured to a precision level of roughly 2µm to guarantee process stability without losing production time.”

“We have now added our third measurement device to the new side grinder - our acoustic sensor that was on the CHD machine. This promotes very fast setups by combining technologies. With the Renishaw probe, we probe the raw and finished tooth, with the measuring cube we measure the grinding wheel and with the acoustic sensor, we are bringing everything together by checking the tooth with the wheel. The wheel senses the tooth and the acoustic sensor knows if we have the right in-feed – making all three measuring devices work together.”

The Vollmer CS860

To achieve such precision demands a robust foundation as Thomas says: “Vollmer is the only manufacturer that uses a concrete polymer base. Very few competitors use a cast iron base; most build machines by constructing steel machined components. Our polymer concrete foundation makes our machines different from our competitors - it puts our quality and precision on a completely different level.”

Productivity

From a productivity perspective, the automatic blade measuring calculation is saving 5-20% of in-cycle ‘air-cutting’, the new saw carrier and flange system eliminate 10-15 minute changeover times, manual measuring of 2-3 minutes per blade is eliminated and there is also the elimination of 25 seconds of non-productive wheel checking, new automated pocket grinding and much more.

Despite all this, Thomas adds: “The new machines are much faster than the older machines. The new base models are 2-4% faster than the old machines and this is credit to the new drive technology. The new drive technology enables us to locate and move the axes more dynamically. This has also enabled the automatic sensing of the grinding passes, which is reducing the air cutting. The machines are consuming upwards of 10% less energy, as the drives are more efficient than before. So, you have 10% less energy consumption with a 20%+ productivity improvement. By adding these factors together, we are reducing the ‘cost per saw’ for our customers and reducing their cost per square metre of production.”

Sustainability

Adding to the reduced energy consumption comments, Thomas is keen to allude to Vollmer’s sustainability credentials: “Vollmer always aims to drive down energy consumption costs for our customers. LED lighting has been used for some time, but we also incorporate technologies like automatic ‘end of shift’ switch off. Furthermore, no Vollmer machines use hydraulic systems. This eliminates hydraulic oil, the potential for spillage or contamination of the coolant and the wider workshop. This also removes the need for filter changes.”

“What’s more, with Industry 4.0, we can undertake service from anywhere. We can update the machine components and software remotely. Our remote system can also email the customer when a batch of saws is complete, or if there is a disruption during a production cycle - emailing the customer their complete machine status. The active dashboard can be accessed via a mobile phone or tablet to provide a complete up-to-date status report.”

Product development and the future

“I’ve been having weekly meetings with my worldwide sales colleagues for over 14 years. We collect all the sales engineers and customer requests - the list is huge. The base point for our development is the well-built technology from before. We analyse the technology and how we can improve the machines, but on the other side, there is a huge list of customer requests or needs. So, we have to understand the customer requests and integrate them with product development - and from that point, we identify what functions we need, and how they can be incorporated into the hardware and software.”

“For example, in the past, we had the electrical cabinet at the back of the machine - but if you have three machines alongside each other, there is only 900mm of space between the machines. The customers have fed this response back to us and on the new machines, we have moved the electrical cabinet to a side where customers would have the gangway.”

With regard to the changing requirements of the market in the face of the pandemic and rising energy costs, Thomas says: “The level of automation is the biggest factor. Machines need to make more and more by themselves. This is what we see in the market and it is one of the most important factors for us. Our Industry 4.0 technology has provided comprehensive remote support during Covid and our energy efficiency and productivity enhancements are reducing the cost per square metre of production for our customers – we will always drive this forward.”

From an internal perspective, Thomas concludes: “We are now moving to a point where 90% of our new machines will be built upon a modular platform. In our ‘frozen zone’ from order to delivery, this time can now be much shorter because we can be more flexible in building up the machine. We can change from one machine to another and add the optional units more flexibly – this will reduce our lead times, costs and increase our production flow.”

0115 9491040

www.vollmer-group.com