Wood coatings should provide the final product with sufficient protection as well as an attractive appearance. The paint layers must be applied perfectly to the surface to prevent stains, wear, orange peel and blistering. As an expert in wood coating, Sames Kremlin offers different approaches for each coating.

When applying stain, the focus is on refining the wood by highlighting the grains, harmonising differences in colour tone and preventing colour changes over time.

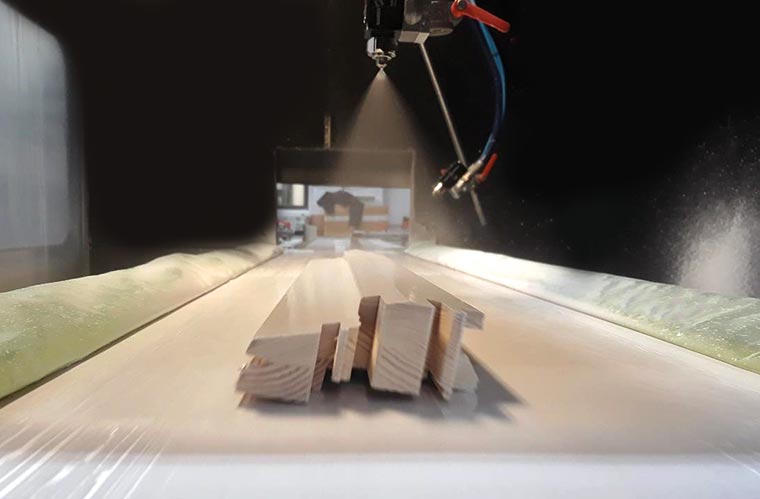

The Airspray product range from Sames Kremlin delivers the best results and revolutionises stain application with the help of the patented Vortex and Restrictor technologies.

Thanks to refined and more efficient atomisation, they prevent common problems such as staining and streaking, halo effects, disharmony in colour matching and shadowing. They achieve good coverage of hard-to-reach areas and, due to minimum overspray, provide better working conditions and reduced maintenance in the booth. Fast coating in just a few passes is possible without having to sacrifice a perfect coat of paint.

Primers are used as an intermediate step in the coating process to ensure even penetration and distribution of stain and topcoat into the wood. Usually PU, acrylic, cellulose and H2O primers are used here, and a single sealing coat on solid wood is usually sufficient.

For this coating step, Sames Kremlin recommends Airless atomisation in combination with the Skill™ nozzles. This technology from Sames Kremlin uses only half as much material pressure as usual and thus reduces evaporation, reduces bubble formation and produces a high-quality surface. The low speed of the paint particles with the Skill nozzle technology allows a shorter distance to the object and results in less overspray. A better transfer rate is achieved and the paint film thickness is higher.

Finally, a top coat is applied to enhance the aesthetics of the workpiece or to provide final protection against dust, dirt and UV. This creates a solid and colourless film, which is usually applied in a single layer at the end.

Thanks to the low paint particle velocity and the additional 0.5 bar atomising air, the Airmix® technology binds sufficient solvent to the paint particle during application. The 0.5 bar of additional air accompanies the paint particle all the way to the substrate, preventing air from circulating around the particles from the outside and allowing the solvent to evaporate.

When applying clear or top coat, the solvent helps to smooth the paint for a particularly glossy and even finish. Airmix® technology thus prevents the solvent from evaporating and causing problems such as orange peel.