The Author M100 and M200 machining centres have the ability to revolutionise the entire industry. These Morbidelli machining centres provide answers to all the problems associated with woodworking and with processing advanced materials – a solution that has been developed to provide a comprehensive answer to requests coming from the market.

The new range features an all-in-one technology: a single machining centre can now provide a solution to the needs of companies and workshops that produce furniture, sound-absorbing panels and speakers, marine products and many more complex products. The benefits offered by SCM’s revolutionary M100 and M200 machining centres are numerous.

The company says there is more free floor space in the plant and absence of perimetral protections offer a better use of production floor plus operators can move 360 degrees around the machining centre. SCM says the Pro Space solution provides big savings in terms of floor space and optimises industrial logistics.

Freedom, flexibility, accessibility and safety

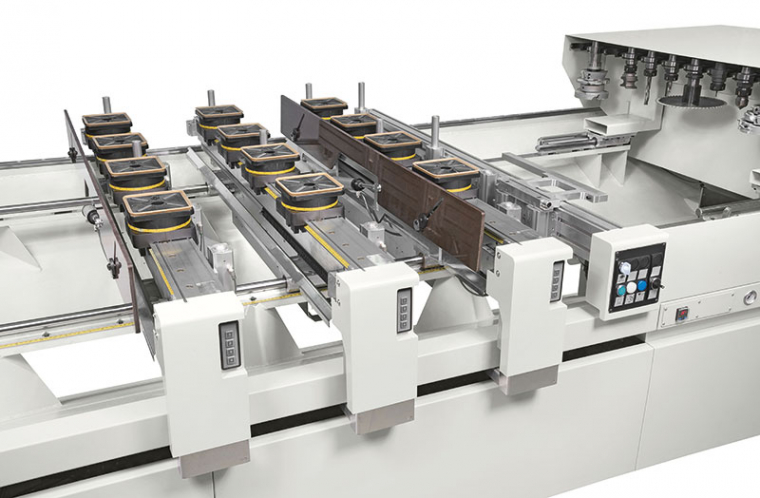

Freedom, flexibility, accessibility and safety is another significant benefit says SCM. The design of the new machining centres allow operators to load and unload large panels safely and freely. Users can load panels of up to 2.21mm wide and 250mm thick. Operator access, and consequent ergonomic benefits, are ensured by the absence of pipes and obstacles on all sides of Pro Space machines, where even the vacuum pump is mounted directly on the machine baseplate.

Absolute flexibility thanks to a configurable operator unit is another noteworthy point. SCM says the Author M100 and M200 have no equal amongst other machining centres on the market because their operator units are the only ones that can accommodate up to four machining units, including a device for inserting dowels using pearl glue.

The company claims unmatched finishing thanks to a five-axis spindle head. Ultra-compact and direct-driven, the JQX (Just Quality eXtreme) spindle head stands out for excellence in its market sector.

Reduction in tool-change times

There is a drastic reduction in tool-change times thanks to the patented Fast 14 system. SCM maintains that tools can be changed between jobs in less than 15 seconds, a solution made possible thanks to a 14-position tool holder mounted directly on the rotating unit which, together with the other machine tool holders, can provide up to 60 additional tools for product manufacturing.

SCM says that the M100 and M200 machining centres offer an impressive 60% savings in drilling cycles, an outstanding result that has been achieved thanks to a drilling head configuration designed to perform any kind of job on any type of furniture of any style.

The Ro.Ax spindles operate maintenance-free for over 1000 hours – another feature that demonstrates how unique the new machining centres are in the category.

No downtime for set-up operations

Adding the TV Flexmatic worktable allows automatic positioning of support bars and suction cups even while the machine is running. The possibility of simply and easily adding all the required suction cups and removing those that are unnecessary makes the worktable a solution that does not compromise performance, thanks to its versatility and free configurability.

Easy and intuitive use of the machining centres

Operating the machine is extremely easy, using an app from the Maestro Suite: setting up the job and production cycles has never been easier. You can use a PC-Office console with a 17in LCD display or a remote TechPad control with which you can remotely operate the machine using its 7in touch-screen to speed up set-up operations.

Extremely fast installation with only one technician and one working day are required to get the Author M100 and M200 machining centres ready and operational. It is another advantage when it comes to maximising productivity and to making the winning machining centre choice.

Affordable all-in-one technology

Thanks to its affordable all-in-one technology, SCM has accepted and won the challenge of offering a product that has no match in the market and that can be configured according to the customer’s needs and investment plan.

Considering their technical characteristics, the Author M100 and M200 machining centres offer an excellent price–performance ratio and are the perfect solutions for processing wood, plastics, solid-wood beams, panels, kitchen cabinets and home and office furniture.