At the recent Ligna event in Germany, Schelling demonstrated that innovation and product development are among its top priorities.

The successful Austrian panel-sizing saws and plants business has completely revised the circular workcell concept of its Lot Size One panel cutting cell, for batch size one production.

The redesigned compact circular workcell concept integrates new and innovative solutions into one overall solution that is attractive both from a technological and an economic viewpoint. Not only does the new system include leaner processes, it also fits into a smaller floor space, offers reduced cycle times, and consumes far less energy than its predecessor.

The new gantry-free circular workcell concept permits almost uninterrupted saw activity. The vacuum manipulators move the strips, without lifting them, from one circulator trolley to the next, using a brush table, facilitating a narrower return conveyor system.

Schelling says the new design of the LS1 really is the next step in automation for panel cutting, and Schelling is showing it off with pride.

Something a little smaller?

Schelling has a vast product range. For smaller manufacturers which cannot justify the use of a large plant, or for a more bespoke solution, Schelling can offer something to get the job done perfectly.

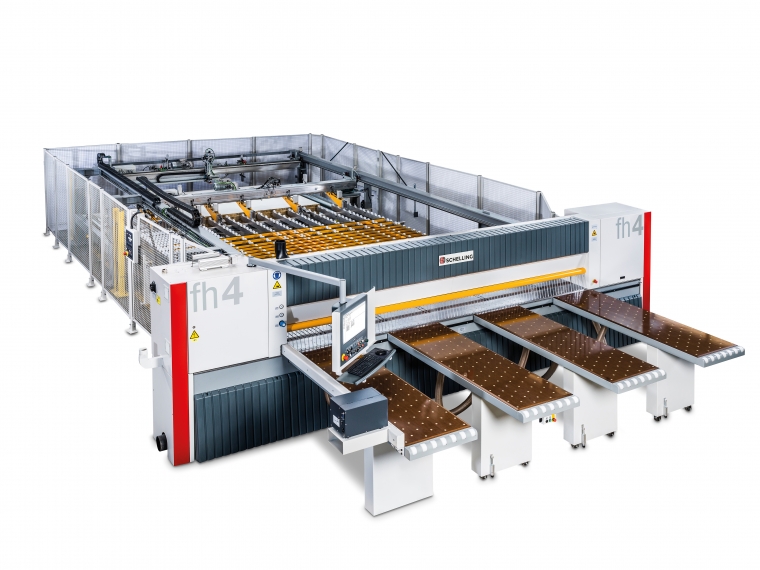

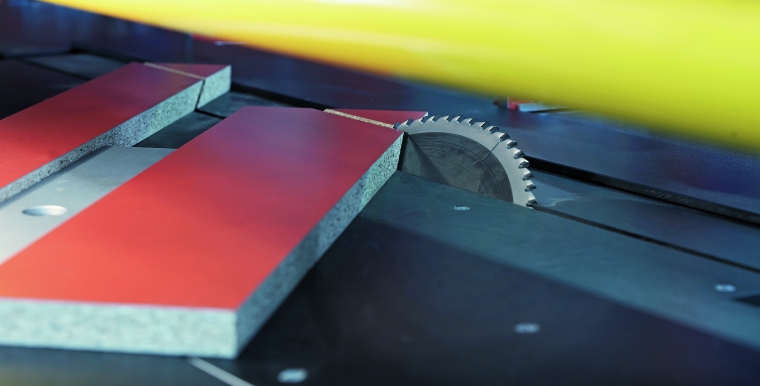

Single cuts or large packages? The fh4 (above) accomplishes any task quickly and efficiently. An additional Duplus2 infeed carriage permits simultaneous cutting of strips with different cross-sectional areas. In combination with a separate sweep-off carriage, the production capacity of the saw can be increased by up to +20%.

The s45 (above), meanwhile, performs mitre cuts of 0-46° effortlessly with the panel sizing cut. All of this is possible up to a length of 5800mm. Also, mitres with glued PVC edging and flat mitre joints can be processed up that length. In this process, CNC axes control the height adjustment and the panel infeed to a precision of 0.05mm.

Pictured: The Schelling LS1