Christian Salvador comments on the presentation of Salvamac’s Q1 2021 results: “The event of our anniversary in March 2021 has been the occasion not only to confirm our choices, show our machines, share our ideas and meet our partners (mainly virtually) as we have done in the past and how we will do in the future, but also to celebrate our results, that are positively surprising us every month.”

Ziemowit Dolkowski, co-founder of Salvamac, says: “Our growth has been more than +50% in recent months, and it was a success that we really did not expect – a success that has not only concerned traditional and already consolidated products, but the entire production range, and which has led us to the creation of something greater … Salvamac Group.”

Salvamac is the result of over 20 years of experience built by its founding partners, Christian Salvador and Ziemowit Dolkowski, who continue to invest their strong passion and deep knowledge for the woodworking machinery sector.

“All this, together with a continuous analysis of the reference market, has allowed us to create a network of contacts and skills, thus proposing our business as an ideal partner for those working in the woodworking sector,” Ziemowit continues.

Salvamac continues to move forward in its social and ethical approach to production and innovation, by creating a group based on the support of four production units in three countries –Italy, Poland and Turkey – to obtain a winning mix of Italian heads and hearts with the dynamics, advantages and competences of various other nations, all in a constant state of evolution.

From this perspective, the Salvamac Group multiplies itself exponentially through three departments: the cross-cutting part, specialised in the cutting and optimisation of wood; the Air&Painting department, where the suction, air filtration and wood painting systems find a reference point; and the brand-new Salvamac Selection, an innovation that represents the natural evolution of the Salvamac project.

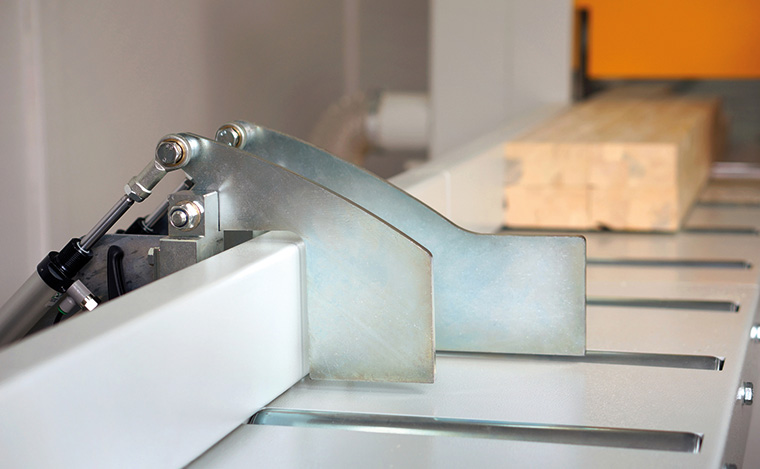

Its primary products (and best known in UK) are the upcut saws, equipped with devices that make them true cutting centres – the Classic cutting saws characterised by Salvamac’s philosophy.

Christian continues: “Our professional cross-cutting saws are solid, resistant, compact. We build them with high-quality materials and complete them with functional options to optimise performance and efficiency.

“But not only solidity – we firmly believe that safety comes first. With our double-button device that is placed in an ergonomic position, and with the protection on the blade, you can work safely – we take care of the precautions.

“Finally, we want to make the job easy, and therefore offer easy-to-use woodworking machines. You have just to choose the stop and press the two buttons to start the cutting cycle, without any adjustment.”

Salvamac’s semi-automatic cutting saws, principally the Classic 40, 50 and 60 models, require limited investment but are a decisive step towards faster, safer and more efficient production.

“It is a coherent catalogue to which it is possible to add new aggregates that significantly increase the performance of these undoubtedly simple machines,” explains Christian, “also by means of intelligent loading and unloading systems, as well as automations that allow even small businesses or sophisticated craftsmen to move towards a completely new perspective.

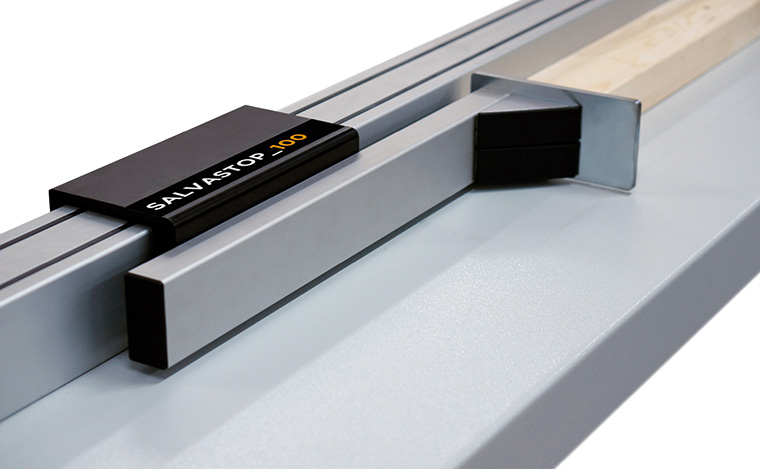

“ Among the aggregates recently launched by Salvamac is the Salvastop measuring-stop device, a system that electronically manages the stopping and positioning of the boards or profiles to be cut, regardless of the material, with high speed and absolute precision, thanks to a state-of-the-art brushless electronic motor.

“Furthermore, the mechanical system has been designed not to require maintenance over time, while ensuring a high degree of robustness and precision.”

Salvastop can be installed on the Classic 40, Classic 50 and Classic 60 models, transforming previously entry-level models into semi-automatic cutting centres, which can be interfaced with the company’s management software (it should be noted that the Salvastop can also be installed on other machines, adapting them to all those applications where it is necessary to provide measuring and cutting operations in an extremely effective way).

Ziemowit continues: “We have worked hard to create the exclusive software very easy to use, thanks to immediately understandable and effective, complete, powerful and flexible graphics.

“It includes five different sections and two different modes, stop or push. Also, it has a 7in touchscreen in an optimum position for reading and programming – not forgetting the included and installed internet teleservice software.

“Due to an innovative technological concept, we have also created a new anodised aluminium beam section of 100 × 100mm, reinforced and with a large thickness to the profile edge.”

This beam has three sides, with groves to adapt and install the structure. One side is a flat fence, to favour the sliding of the wood on the guide, so avoid wear and dust problems.

Thanks to the scale of this solution, the pusher carriage reaches a movement speed of up to 60m/min. The transmission system has a 32mm wide-toothed belt, with high-precision internal steel cables, ensuring a wide capacity and a very high positioning tolerance.

The machined steel heads are robust and independent, designed to have a long life, highly reliable and precise, while the compact Servo Drive electronic motor guarantees simplicity, reliability, durability and efficiency. With this innovative technology, customers can manage closed-loop positioning, checking the position at any time – even in case of heavy efforts and accidental external pressure.

The motor, which is mounted in a pulling position, has a power of 11Nm, and the electrical and electronic inputs and outputs are integrated upon the engine itself. Finally, the emergency and start buttons are ergonomically positioned, to better facilitate the operator’s work.