This artificial intelligence optical system, which Altendorf is proud to claim is a world first, offers protection to people, machines and the material itself. Working as a unique early detection system with two cameras, the product revolutionises sliding table panel saw safety. There’s no damage whatsoever to the saw if the safety system is activated, and it’s immediately ready for use again.

The system works with all materials – plastics, non-ferrous metal, dry and damp wood, panels, etc – specified gloves, any type of saw blade with a diameter up to 550mm, as well as single and two-way tilting machines.

Why is the hand guard needed?

In 2019, 971,547 occupational accidents were reported, 1,554 of which occurred while using sliding table circular saws. This is the equivalent of 6.7 accidents per day, which costs employers between €9,700-€16,300 due to employee absence and the associated costs – not to mention lost orders and increased insurance costs.

From these hand accidents, 47% are injuries that have had an effect on the pension, meaning injuries so heavy that the operator can no longer continue to work as they did before (Source: DGUV, Germany).

“The trade will see massive benefits from the Hand Guard machine, as it re-enforces the correct operation of a panel saw while protecting operators, workflow and production

Two cameras for early detection

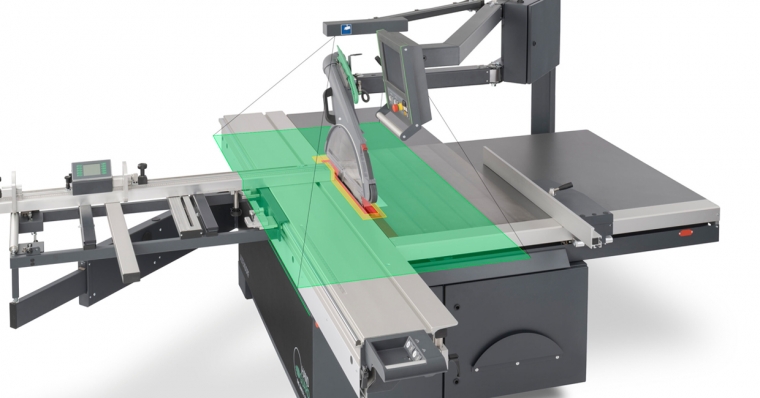

Hand Guard is based on the early detection of a dangerous situation. Two powerful cameras determine the exact position of the hand in relation to the saw blade. In the process, differently defined situations are optically recognised and classified.

The cameras constantly collect data, which is processed by a powerful hand detection programme. If the system detects a hazardous situation, the danger is eliminated in a quarter of a second.

Altendorf Hand Guard – Winner of the German Occupational Safety Award 2021

Altendorf is proud of its “leading international innovation for circular saw safety systems”. The safety system for this product category is a milestone in occupational user safety. It prevents injuries caused by workplace accidents and was recently awarded the renowned German Occupational Safety Award 2021 in the ‘Operational’ category.

Key advantages of Hand Guard, compared to other systems

The system reliably protects against hand injuries at normal working speeds, as well as fast hand movements of up to 2m/s. AI reliably detects the human hand – with and without gloves. Saw blades of all applicable diameters can be fully lowered. Workspace monitoring enables timely danger detection. Controlled lowering of the saw blade when triggered – fastest system on the market – with immediate resetting and no need to re-teach the machine. Intelligent system – AI gives a continued learning capability – the system self-monitors and improves. True safety system through consistent two-channel design.

“Alternative safety systems such as ‘SawStop’ have been on the market for a while; these use older technology,” explains Justin Inman, MD of R&J Machinery. “As the market leader for sliding table saws, Altendorf has always discounted introducing capacitive systems that have been adapted by others, as they have only a single channel of detection, are hard wearing on the machine when triggered, and the danger detection zone is so small that there’s still great risk of injury to the operator, especially when working at normal speeds.

“Years of development from Altendorf have resulted in the Hand Guard system we see today, which, put simply, will ‘revolutionise Panel saw safety’. Hand Guard utilises the latest technology available today and is the solution the market expects from Altendorf.

“The trade will see massive benefits from the Hand Guard machine, as it re-enforces the correct operation of a panel saw while protecting operators, workflow and production, as well as preventing potential costly injury claims and fines from HSE.”

01455 840224