NEY has sold EBM edgebanders exclusively for the past for decades and have hundreds of very satisfied customers.

The new 2020 range gives manufacturers the twin benefits of greater productivity at prices 20-30% lower.

EBM KDP 72

Ideally suited to the lower volume manufacturer that needs a reliable machine with a small footprint capable of edging panels with materials up to 2mm thick. The machine is single phase and therefore well suited to the smaller workshop.

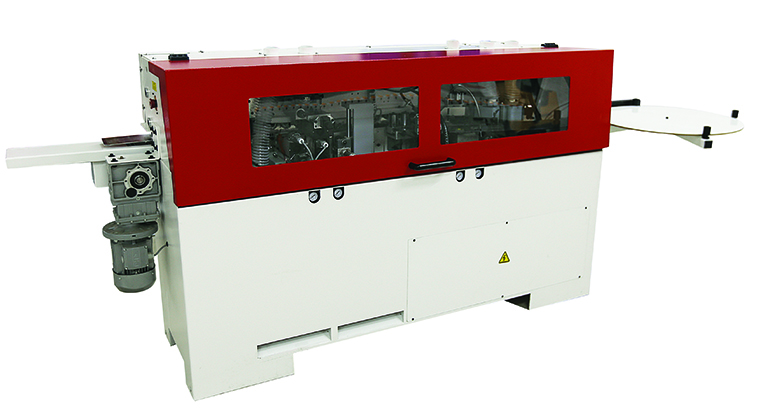

EBM KDP 74

The next machine in the range has two diamond pre milling cutters to rectify the panel edge offering an excellently finished panel. It is ideally suited to customers who are cutting with a panel saw and may suffer with chipping or scriber marks. The machine has top and bottom profile scrapers and buffing.

EBM KDP 135

This machine is ideally suited to manufacturers that need a reliable yet faster machine with a pre milling capability to produce a well finished product. The feed speed of 13m/minute makes it highly efficient. An intuitive touch screen controls all of the machine functions and is conveniently mounted at eye level at the infeed end of the machine. Premilling, scraping and buffing are standard.

EBM KDP 136

The next machine in the range is ideally suited to the manufacturer that needs a reliable machine with a pre milling capability and corner rounding to produce a well finished product at a reasonable cost. The feed speed of 13m/minute makes it highly efficient for the smaller to medium sized manufacturer. Premilling, corner rounding, scraping and buffing are included.

EBM KDP 208

The KDP 208 is a complete solution for the medium sized to larger manufacturer and features diamond pre-milling blocks, two independent end trim saws and a two motor corner rounding unit. The combination of this allows the machine achieve 20m/minute on straight edges and 12m/minute when corner rounding. The machine has a full colour touch screen located at the infeed end of the machine to select the woking units, glue pot, track speed etc. Scraping and buffing standard.

024 7630 8100

www.ney.co.uk