Ready-to-assemble furniture has a reputation for being time-consuming and complicated to put together. Many of today’s products don’t deserve this reputation, but there’s always room for improvement, says Gary McMahon of Titus, who offers a simple approach for assessing assembly friendliness.

The majority of people find the prospect of putting together ready-to-assemble (RTA) furniture daunting, so suppliers have much to gain by building a reputation for products that are fast and easy to assemble. Hearing a friend say that they have never had any problems with RTA furniture from brand XYZ is a powerful recommendation.

Increasing ease of assembly is therefore a key ambition for furniture manufacturers. But how can this be done? The first step is to note that if you want to control something, you have to be able to measure it. Measuring ease of assembly, however, isn’t particularly intuitive – at least it wasn’t until Titus developed the concept of the Consumer Assembly Friendliness (CAF) score.

The CAF score is a numerical measure of how easy a piece of RTA furniture is to put together. It’s easy to work out, and it’s not tied to Titus products, although the company naturally hopes that furniture manufacturers will work with Titus to develop ways of reducing their CAF scores.

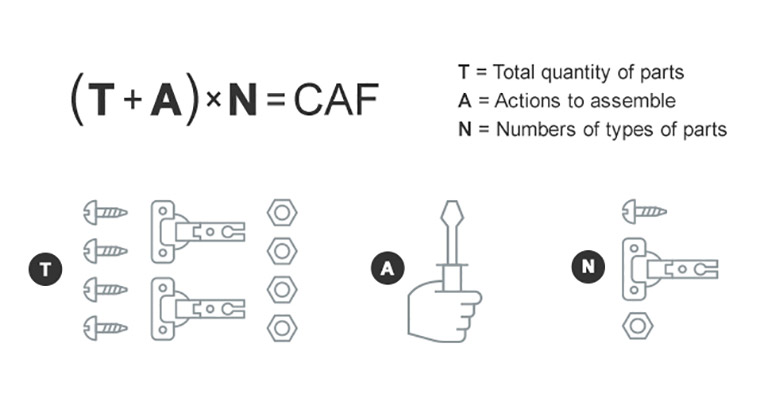

The CAF score is calculated from this formula: CAF = (T + A) x N

Where T is the total number of parts, A is the number of actions it takes to assemble them, and N is the number of types of parts.

Let’s look at an example that, for the sake of simplicity, deals only with part of the assembly process – joining a cabinet side to a base using two wooden dowels, two metal dowels that screw into place, and two cams. The wooden dowels are supplied in a sealed plastic bag. The metal dowels and the cams are in another sealed plastic bag. The side panel and the base have protective cardboard overwraps.

We have eight parts, including the side panel and the base. Assembly involves 17 actions: open the bag of wooden dowels, open the bag of metal dowels and cams, remove the cardboard from the side panel, remove cardboard from the base, insert the two wooden dowels, screw the metal dowels into place (three turns each, so count three actions per dowel), insert the two cams, mate the panel to the base, and tighten the two cams. Finally, we have five different types of parts (side panel, base panel, wooden dowels, metal dowels and cams).

Putting these numbers into the formula: CAF = (8 + 17) x 5 = 125

Computing the CAF for a whole item of furniture involves a bit more work, but it’s still straightforward.

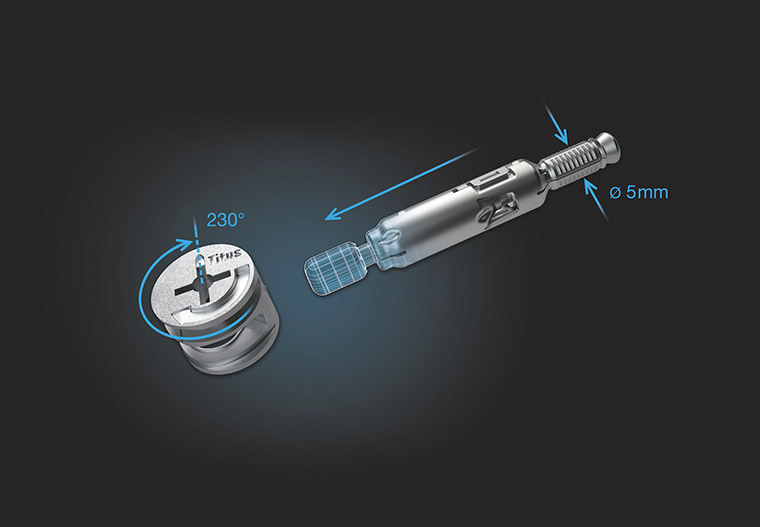

Let’s see how that CAF score could be improved. We could use the latest TL5 full metal jacket-type cam-and-dowel connectors.

These don’t need to be supplemented by wooden dowels and, instead of screwing into place, they push into predrilled holes. Now we only have six parts, nine actions, and four types of part, so: CAF = (6 + 9) x 4 = 60

That’s a big improvement for a modest change.

Of course, there are other options. These include using one-piece connectors and systems that allow cams and dowels to be pre-inserted at the furniture manufacturer’s factory.

The CAF scoring system applies not only to connectors but also to other components, so it is possible to calculate a CAF score that covers all aspects of furniture assembly. Manufacturers who do this have a reliable metric for assessing the user impact of any changes they make. And, when making changes, it is worth remembering that leading cabinet hardware manufacturers like Titus are constantly enhancing their products, so it is worth getting up-to-date advice. The best solution from a year or two ago may well have been superseded.

Ease of assembly for RTA furniture can make the difference between a product that’s successful and one that isn’t. Using CAF scores provides a reliable way of measuring ease of assembly and, by combining CAF scoring with the latest developments in cabinet hardware, furniture manufacturers are in a better position than ever to maximise the consumer appeal of their products.