Pictured: Maka is one of the first machine manufacturers to introduce the new Siemens SINUMERIK ONE control

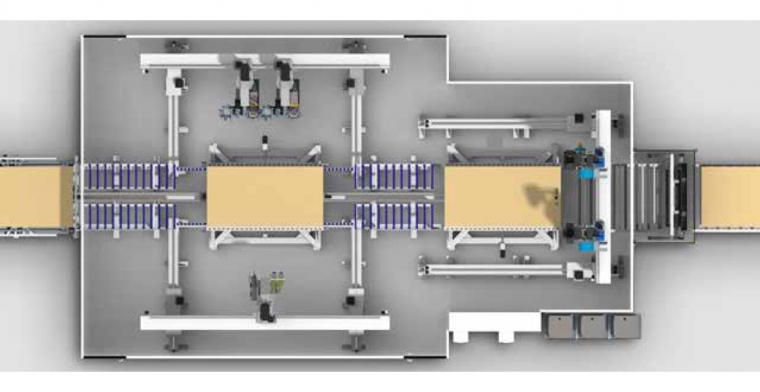

Maka, known for providing bespoke and high quality CNC machining centres, has introduced a new and innovative Door Line, to batch process doors from stack-to-stack. The new STB-SPEED will maximise output and productivity for any high volume door producer.

Maka, which specialises in providing bespoke manufacturing systems for specific applications, has applied their vast experience and know-how supplying production lines worldwide, to automotive, construction and door manufacturers, to full effect with the new Maka STB-SPEED range

Based on an original and novel through-feed central transport system, the design enables more working units to be employed and operate simultaneously. Machine functions are masked, minimising the effect non-productive machine cycles would otherwise have on the cycle time and ultimate capacity.

Maka’s transport system takes each door through machining stations, quickly and precisely, and being compact and modular, allows more working units to be employed in the line.

The STB-SPEED consists of modular working units, selectable according to the customers own requirements, for:

- Lock and Handle operations

- Hinge plate machining

- Window and letterbox apertures

- Spy-hole drilling

- and Cleaning

Combining five-axis profiling with through-feed edge processing, Maka’s STB-SPEED-FLEX-5 delivers ultimate flexibility, with non-stop high-volume through-feed door production

Depending on the level of operations required, and the space and capacity required, the modular STB-SPEED can be supplied with additional stations for:

- Second Lock station

- Insulation and soundproofing

- 3 or 5-axis routing and drilling.

Doors large and small, (sizes from 450 to 1000 mm wide and 2050 mm high), and of various construction types from lightweight interior doors, to heavy Fire-doors, and solid hardwood exterior doors, can all be processed by the new STB-SPEED.

If supplied initially as a stand-alone manually fed line, the operator will benefit from the standard auto-aligning infeed table provided with the base format. This also enables future automation to be retrofitted at a later date, ensuring the investment is future-proofed.

Automatic Material Handling modules for unmanned operations are also available for:

- Stack handling

- Feeding

- Stacking

- Tilting

- Turnover, and

- Hinge and Lock Insertion

- Multi-drilling, and

- Turret head aggregates

Pictured: Automatic in-line hinge insertion in action

Automatic setting, precise transportation, and laser positioning cuts programming and setting times, and guarantees consistent precision and quality.

Minimal tooling and maintenance costs have also been carefully considered. Tooling is designed for standard HSK-F63 holders.

Dust extraction and the complete management of waste materials, including offcuts, are also taken care of by integral waste management collection chutes and integral dust hoods directly at the point of machining.

The ingenuity of the new STB-SPEED has been made possible by Maka’s adoption of all the power and flexibility provided with the new Siemens SINUMERIK-ONE control.

Maka takes full advantage of the technical power provided by the ONE. Combined with state-of-the-art networked production and control technology, the STB-SPEED is provided with comprehensive control and monitoring of all modules and individual devices, not only the transport, but also the aligning clamping, positioning, measuring, sensing and handling.

Processing Speed is the ultimate goal. Maka’s transport system is matched by the speed and precision at which the modular units operate. Tools work at the highest cutting speeds, altogether resulting in the shortest possible processing times.

Each line can process several doors per minute, depending on the modules and complexity of the processes required.

Maka’s exciting and innovative door lines are designed without compromise to maximise productivity and user’s ROI.

The STB-SPEED’s heavy-duty construction upholds Maka’s long standing reputation for quality, reliability and long-life.

For further details, contact MAKA via Iain Young directly on 07836 295434.