HOMAG is proud to claim that its intelliGuide operator assistance system is the first assistance system in the history of panel dividing and drilling technology to enable saw and drill machines to interactively respond to the operator. This means that the operator has full control over production processes whilst benefiting from faster operating procedures and significantly increased production efficiency.

The intelligent and flexible system has a modular structure made up of many different components. Together, they convert the saw and drill machines into intelligent systems that react to the operator’s actions. The intelliGuide system allows the operator to work more quickly, easily, ergonomically and intuitively.

The machine’s benefits at a glance

Completely intuitive machine operation that leads to significantly shorter throughfeed times and increases the output Systematic means of avoiding errors Fast processes: operator and machine work in tandem The operator can work without looking at the monitor Fluid, ergonomic processes for efficient and focused work Smooth change of operator possible at any timeClassic, advanced and premium models offer different options and features

HOMAG’s intelliGuide operator assistance system is offered in three models with differing levels of assistance technology for varying demands. It starts with the basic model – the intelliGuide Classic system – and goes up to the intelliGuide Advanced and Premium systems.

intelliGuide Classic efficiently guides the operator step-by-step via a 3D model on its monitor. The machine is intuitive to operate thanks to coloured LED signals which means that the operator rarely has to look at the monitor, facilitating efficient and focused wood processing.

intelliGuide Advanced raises the interaction between humans and machines to a new level. With the addition of a camera system, the operator can respond to the handling instructions from the saw, while the saw reacts to the operator’s actions.

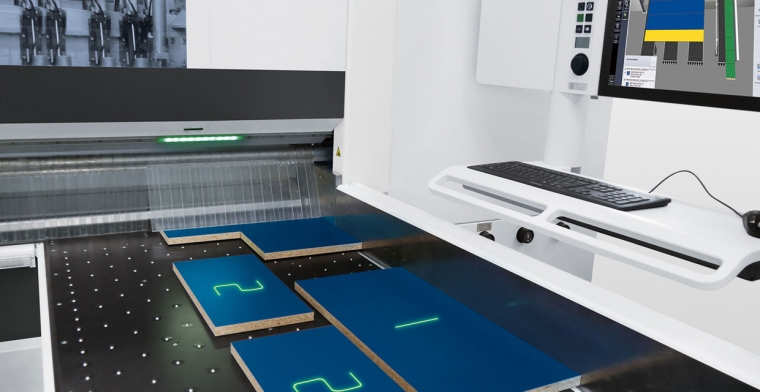

intelliGuide Premium works with innovative laser projections. These support the operator with additional instructions directly on the workpieces or in the working area. All handling instructions and information are shown clearly and visibly in the range of vision for processing. This means that errors due to misunderstandings or lack of attention are almost completely excluded.

Drilling and fitting insertion CNC machining centre operator assistance

HOMAG’s Classic intelliGuide system is available as an optional extra on HOMAG’s DRILLTEQ D-500 vertical CNC processing centre. It is a standard feature on HOMAG’s new space saving DRILLTEQ V-310 vertical CNC processing centre.

On these DRILLTEQ CNC processing centres, the intuitive intelliGuide system enhances workpiece and tool change handling to increase efficiency and ensure process reliability. Tools can be transferred from the tool management system ‘toolManager’ to the picker simply with a tap of a finger. The intelliGuide system then indicates where the new tool should be placed in the tool changer.

To further support the machine operator, the loading area of the DRILLTEQ V-310 is also equipped with the intelliGuide LED assistance system. Here, intelliGuide is linked to the control system and shows the workpiece sizes and the correct positioning for loading into the machine by illuminating the LED bars in the X and Y directions.

Quick visual checks guide the operator to ensure the loading of the correct sized workpiece. The intelliGuide system also performs a plausibility check to measure the length and width of the workpiece. This makes sure that drill positions are accurate even if workpieces are presented slightly over or undersized.

Operator guidance for HOMAG’s SAWTEQ panel dividing saws

All three models of the system are available for the SAWTEQ B-300, B-400 and B-500 panel dividing saws with and without a lifting table, in the cutting lengths 3200, 3800, 4300 and 5600mm. HOMAG’s SAWTEQ B-130 and B-200 panel dividing saws can be equipped with the intelliGuide Classic operator assistance system.

Intelligent machine operation and operator assistance

Enthusing about the use of the intelliGuide system on HOMAG’s panel dividing saws following its launch, Jörg Hamburger, Product Manager for Panel Dividing, HOMAG says: “Up until now, the saw determined the production sequence, expecting certain actions from the machine operator. We wanted to reverse this relationship. Our saws should react intelligently to the operator and guide them through processing in an optimal way. intelliGuide embodies this approach in an implementation that is unbeatably effective and unique worldwide.

“Thanks to continuous further developments, intelliGuide has also established itself as an optimal tool for training employees. It is simple and intuitive to operate, setting new standards in human-machine interaction.”

For more information, visit www.homag.com and watch the intelliGuide product video. For a demonstration or further information on HOMAG’s machinery or software, contact Adele Hunt at HOMAG UK on 01332 856424.