HOMAG is marking a significant milestone: 25 years of pioneering window production solutions. Since the introduction of its first CNC technology in the late 1990s, HOMAG has consistently led the way in developing automated solutions for window manufacturing. What started as a response to the need for handling diverse window construction without manual tool changes has evolved into a robust line of machines that have transformed the industry.

A legacy of innovation

Since 1999, HOMAG has been at the forefront of creating state-of-the-art CNC window production technology. The journey began with the introduction of the BOF 311/40/PM, the company’s first machine designed with a specific clamping system for window scantlings, delivering unprecedented performance and laying the groundwork for further innovation.

Key developments included the Flex5 unit in 2004 for versatile sawing, routing, and drilling at any angle, and the chain changer for quick tool changes. In 2008, HOMAG launched the powerProfiler BOF 700, an automatic machining centre featuring the innovative MA table for automatic reclamping.

The powerProfiler 2 was unveiled in 2011, boasting a new design for improved efficiency in automated window production. In 2014, HOMAG introduced the next generation of powerProfilers with extended functions, including 3D clamping technology and the Tooltower tool storage system for faster changeover times.

Two decades of development came to a head in 2018 with a significant design change and the rebranding of the powerProfiler series to the CENTATEQ S-800/900 – a stark indication that HOMAG, and by extension the window manufacturing industry as a whole, had entered a new era.

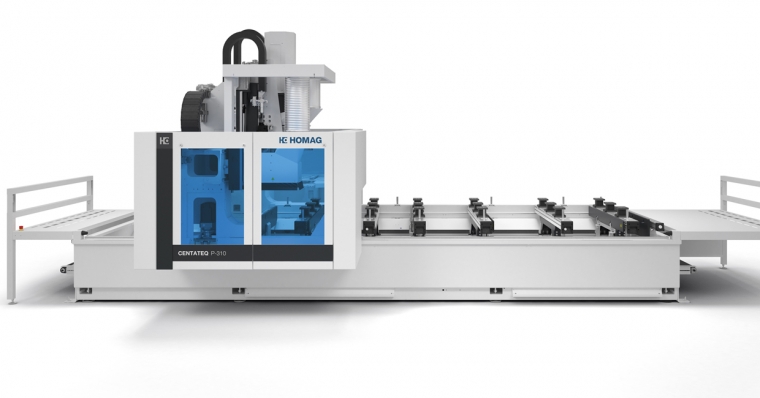

HOMAG CENTATEQ P-310

The latest luxuries

The culmination of HOMAG’s 25-year legacy can be seen in its latest CENTATEQ series, which represents the pinnacle of window production technology. Each machine in the series – CENTATEQ P-310, CENTATEQ P-510, and CENTATEQ S-800/S-900 – has been designed to meet the demands of modern manufacturers, combining sophisticated technology with user-friendly operation.

The CENTATEQ P-310 is celebrated for its versatile performance in CNC processing. Its compact design and customisable configuration with a great choice of clamps and fixtures makes it ideal for window/joinery production. The machine’s advanced area scanner technology (safeScan) ensures safe and efficient operation without compromising productivity.

“We were asked the other day what was the key benefit of the new HOMAG CENTATEQ P-310 to our business, and I blurted out: ‘You can make money using it!’”, praises Ryan Woodward, Director at French & Westcott, who was recently interviewed regarding his company’s investment in the P-310. “And ultimately, that’s what it’s all about. We now process almost every component of a window or door on the CNC because it is so much quicker and more accurate. It is a real game-changer, without a shadow of a doubt.”

Similarly, the CENTATEQ P-510 takes production capabilities to the next level, offering a complete system for the most demanding production requirements. With scalable performance and a moving gantry designed for high-precision work, this machine is ideal for manufacturing stairs, furniture, doors and, of course, windows. Its innovative design allows for complex tasks to be handled efficiently, meeting diverse customer needs with exceptional accuracy.

Last but certainly not least, the CENTATEQ S-800/S-900 models, which stand out as the ultimate solutions for automated window production. Designed for both entry-level applications and high-capacity industrial operations, these machines offer automated loading and clamping, multi head four- & five-axis technology and independent part processing capabilities. The series supports continuous, multi-shift operation, significantly increasing throughput.

“The results we’ve achieved with this new machine have been outstanding,” shares Dion Panting, Managing Director at Mumford & Wood. “We even managed to process 270 components in one nine-hour shift, which is unheard of in complex window manufacturing. Every part comes off correct and finished to the premium quality standards we demand.”

Looking to the future

Even as HOMAG celebrates this significant milestone, the company remains focused on the ever-evolving demands of window manufacturing and finding new ways to give its customers a razor-sharp, crystal-clear edge.

There’s no telling what the next 25 years will hold for HOMAG. But given its history of innovation, its active adoption of the latest technologies, and its commitment to evolve alongside the needs of its customers, it’s safe to assume there’s plenty more where that came from.

For more information or a demonstration of any of the HOMAG machinery and software, contact Adele Hunt at HOMAG UK on 01332 856424.