When buying new machinery, are you always comparing apples with apples? On the surface, beam saws may look very similar, and in theory, they should all perform the same task – but that doesn’t mean they will perform these tasks in the same way, or to the same standard. The Tectra 6120 beam saw series from Holz-Her proves this point perfectly.

TECTRA 6120 classic with air flotation table

Built to fulfil highly specific customer requirements and flexible production quantities, the Classic Tectra 6120 beam saw combines compact dimensions with maximum performance. Featuring a powerful 7.5kW motor as standard (or an optional 11kW motor) for optimum sawing of stacks or high speed rough cuts, an impressive cutting projection of 82mm and cutting speeds up to 100m/min, it offers robust and precise cutting of materials measuring up to 4400mm x 4250mm and features a wealth of intelligent ‘smart factory ready’ functions designed to automate your production line and increase productivity.

Floating workpiece clamps can compensate for the unevenness of a panel and prevents damanage to the panel surface

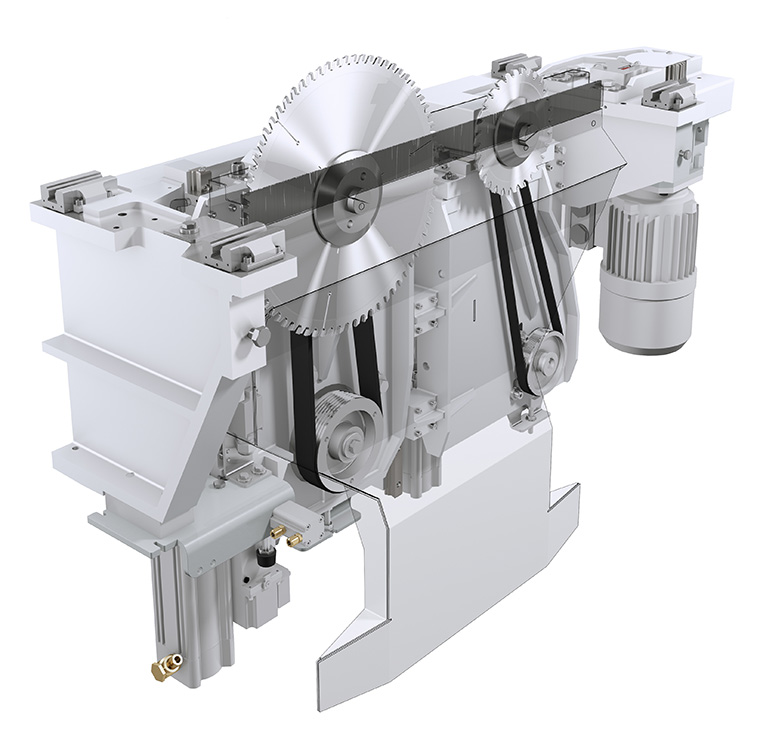

Made of only two parts and featuring 25mm solid steel plates on the table tops, the state-of-the-art pressure beam saw has been built to last. To ensure high-precision guidance and longevity, the CNC inspired saw carriage has movable axes and fixed linear guides that are backlash-free and guarantees dynamic repeatable performance. This means, unlike machines with ball bearings, the Tectra 6120’s linear guides are maintenance-free and come with a 10 year guarantee.

The saw benefits from a seperate main blade and scorer motors and a fully adjustable electronic grooving unit and scoring blade as standard

The saw also benefits from separate saw and scorer motors and includes a fully adjustable electronic grooving unit and scoring blade as standard for precision cuts and speedy changeover times. A reinforced fence and solid front table add to the warp-resistant construction, while suction channels have been added in favour of hoses for effective dust and chip collection directly from the source.

The Tectra’s 6120’s linear guides are maintenance free and come with a 10 year gurantee

To ensure easy handling and the light movement of panels, the Tectra series features a unique air-cushioned bed before and after the cutting line – designed to withstand even the heaviest of panel packages – and features intelligent floating clamps.

Floating workpiece clamps can also compensate for the unevenness of a panel, preventing damage to the surfaces. This, plus the added benefits of a pneumatically controlled angle presser unit (up to max. 1,200 mm), direct rack-and-pinion drive and a proximity-type sensor, guarantee secure and accurate positioning of panels and reduce cycle times.

At the heart of its design, the Tectra 6120 beam saw is controlled by Holz-Her’s Cut-Control 2 software package, whilst a 19-inch control terminal allows you to program the cutting height, groove depth and pre-cutting settings directly onto the machine. The screen also offers a large viewing platform with 3D real-time graphics and graphical processing support.

Holz-Her’s pre-installed Quick-Work software can create a fully optimised cutting plan in just three clicks

In addition to this, Holz-Her’s pre-installed Quick-Work software can create a fully optimised cutting plan in just three clicks and, with the addition of a fuss-free, ‘drag and drop’ Easy-Plan tool to create and amend cutting lists and Opti-Cut software to provide a complete and effective cutting solution that oversees everything from material management to finished parts lists, it has never been easier to create, adapt and optimise cutting plans for a wide range of applications.

Keen to see the Classic Tectra 6120 beam saw in action? Pre-book a personal machinery demonstration at Holz-Her’s showroom in Oxon.01235 557 600

www.holzher.co.uk