UK sanding technology manufacturer, Gibbs Sandtech, has, over the years, successfully developed a range of machinery and ancillary items for the UK woodworking sector. Having been successfully supplying the industry for the last 60 years, they are continually advancing new ideas and technologies in to their product range.

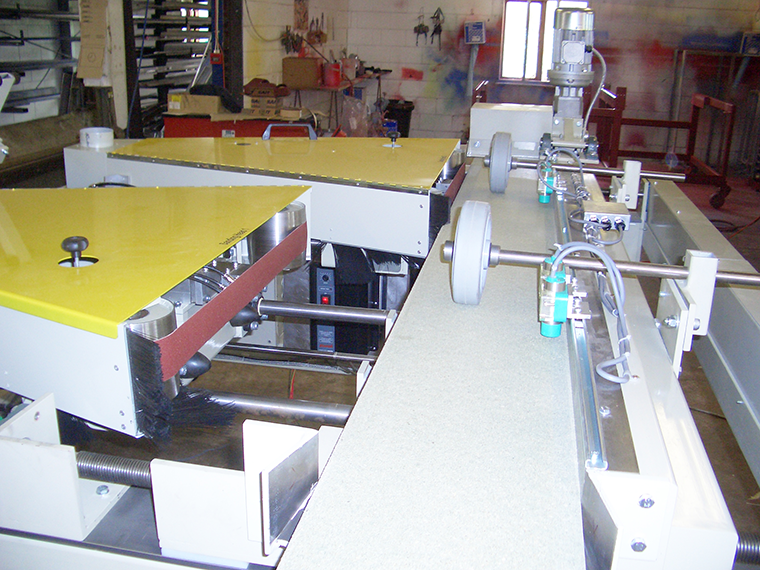

The latest development is a unique through-feed denibber, called the CB. It is available in 630mm, 930mm and 1330mm widths. It has a very low entry level price tag, yet Gibbs says that it comes with all the features of high end machines. The CB boasts full variable speed control for all functions, along with electric rise and fall for the brush sanding heads.

“The unique oscillating sanding brush system is capable of sanding and denibbing complex raised and fielded doors, shake style doors as well as flat panels,” explains Gibbs Sandtech director, Warren Gibbs.

“The machine can even be fitted with wire brushes to give a grained effect on solid wood frames, complete doors, as well as flat veneered panels.

“The heart of the system is a very special brush and abrasive system, also manufactured at the our factory – the abrasive system is available in the full grit range and different length brushes and abrasives. This gives the user great flexibility in achieving the desired sanding.

“The CB also has very low running costs, with customers only having to replace the abrasives around once every three to six months and replacement sets, starting from under £100.

“Being a fully UK-produced machine, at the our factory in Hertfordshire, so quality and precision are guaranteed – to ensure peace of mind all machines are sold with a full 12 months warranty.”

Gibbs has also invested time in designing optional extras, such as side sanders for the edges and cleaning blow bars which, according to Gibbs, leaves the exiting panel 100% dust free for spraying.

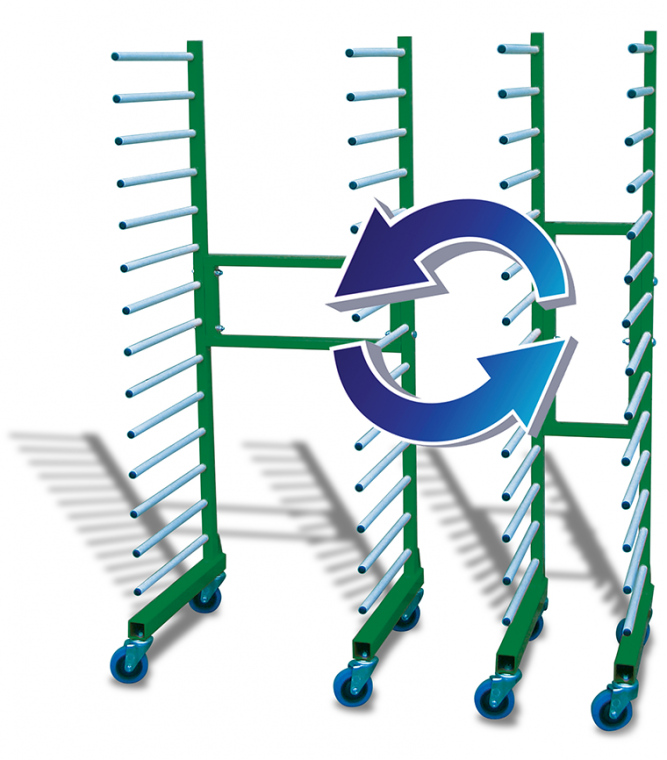

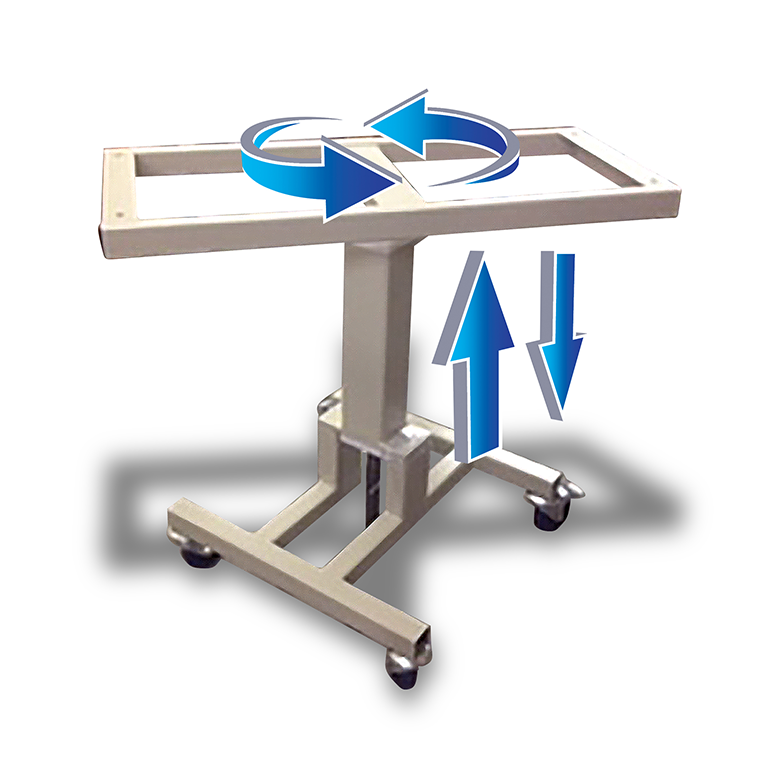

“The CB’s denibbing results are second to none, as demonstrated by numbers of machines that have been sold over the last few years. We have also developed a great range of mobile drying racks and spray tables. They are suited for small and large operations alike. All the racks and spray tables are designed and manufactured in-house and fit budgets and requirements from one man workshops to large finishing departments,” says Warren.

Along with a standard range, Gibbs also offers custom designed racks and spray tables to suit customer’s exact needs.

In addition, the company also offers custom-made machines, providing a one-stop shop, from in-house design, manufacturing and installation. Having been making custom machines for over 40 years, Gibbs has a wealth of knowledge and experience in many areas – customers from small companies to multinational PLC’s have had machines built by Gibbs Sandtech.

Projects generally are never the same,” says Warren, “and we work with a blank sheet of paper at the initial concept stage so the finished design can meet every detailed requirement of the customer. Most are truly unique designs suited to individual processes incorporating handling, machining, clamping or sanding processes.”

Gibbs also has a wealth of experience in RF (high frequency) used for rapid glue curing – sometimes combining several processes in to one machine. Concluding, Warren says: “Custom designed machines can sometimes be a standalone unit, part- or even an entire production line. For any custom or unique requirements, then the one stop shop of Gibbs Sandtech should definitely you first port of call.”

01920 822404

[email protected]

www.gibbsfinishing.com