The IT70 technology represents a quantum leap forward versus this method, both in terms of quality and productivity

.

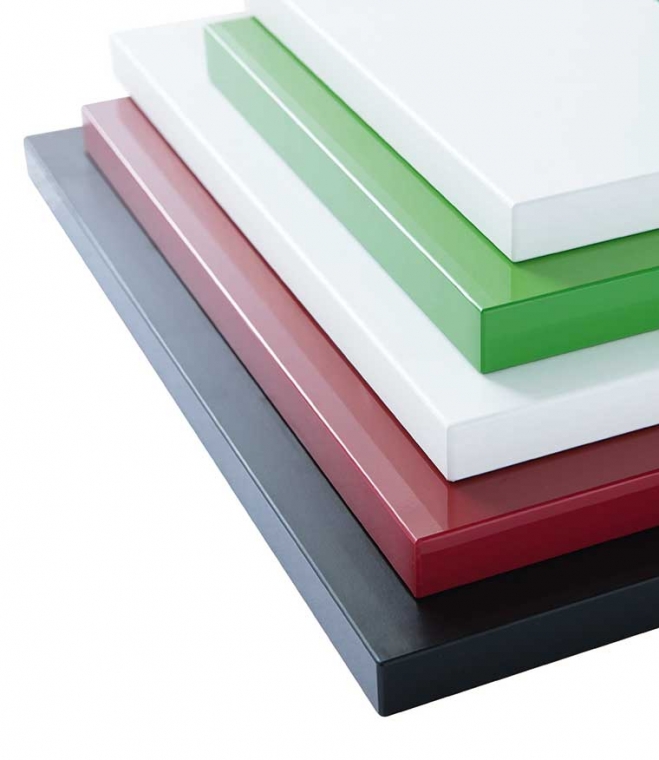

Biesse’s IT70 linear edge trimming unit is now available on the Akron 1400 edgebander as Biesse cascades down its top level technologies throughout its range, giving mid-sized operations the opportunity to achieve the optimal finish that is usually the preserve of large capacity machines.

For many years, the industry standard for trimming excess edging tape, so it is flush with the panel, has involved a process that incorporates two inclined motors. These track the panel at a 45° angle to ensure a clean and accurate cut.

Adopting a linear approach

Biesse says its IT70 technology represents a quantum leap forward versus this method, both in terms of quality and productivity.

The unit was originally engineered to work with high performance edgebanding machines, where precision and speed are paramount, and employs a completely different trimming technique. Instead of using a frictional copier that slides down the front and back edge of the panel, on the IT70, the saw follows the length of the panel horizontally and uses reference points to locate the panel as it travels before cutting the edge tape.

According to Biesse, there are two key advantages with this technique: firstly there is no friction between the panel and copiers – the saw simply locates the panel and cuts off the overhang. This results in a superior finish by preventing the problem of witness marks being left on the panel. Secondly, it reduces the gap between each panel, which allows more panels on a machine at the same time. Productivity can be improved by 30% in some cases.

Biesse’s IT70 linear edge trimming unit is now available on the Akron 1400 edgebander

The Biesse advantage

Whilst other manufacturers have a linear option within their portfolios, Biesse says its IT70 leads the pack in terms of its price:performance ratio claiming superior engineering and the use of the latest technologies such as linear guides make for a unit that guarantees unrivalled longevity and reliability. The IT70 is available in both servo and pneumatic configurations.

The unit can be supplied with a numerical control (NC) guide system for automatic offset adjustment. This feature is particularly useful to accommodate edge tapes from different suppliers as their thickness dimensions can vary. Without this, the operator would need to manually reset the machine to accommodate for the variation in tape thickness.