There is a lot to think about when selecting the correct insert nut for a job. The thread size and length of insert required are often determined by the fixings being used and the timber thickness – but there are more options.

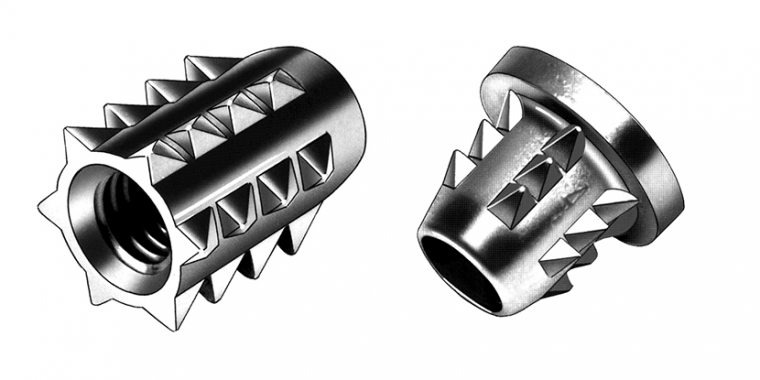

Consider the forces in play in the joint where the insert nut is to be used. For a lightweight application, an A-type or B-type knock-in insert will probably be suitable. They tap quickly and easily into a pre-drilled hole, while external barbs prevent spinning and offer a good level of pull-out resistance, particularly in hardwood and plywood.

Type A inserts are unheaded, so they can be embedded in the timber for a flush fit. Type B has a flanged head, which prevents pull-through when bolted from the underside.

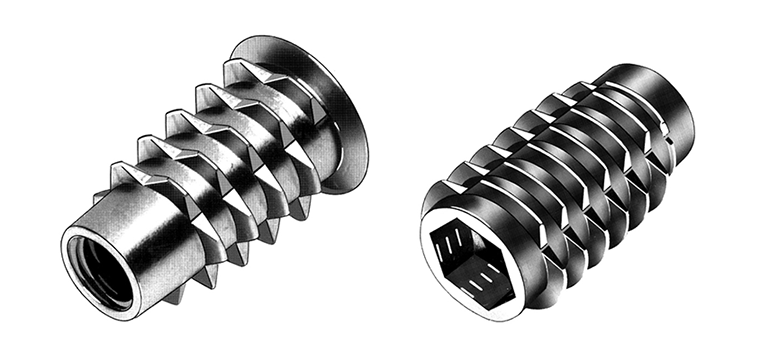

Screw-in and specialist insert nuts

Screw-in Type D and Type E insert nuts offer a greater degree of hold-in and a higher resistance to vibration, thanks to the external, self-tapping thread. The hex head makes fitting quick, accurate and easy, using a hexagon driver or Allen key. This makes them well suited for use in softwoods and chipboard. The flange on the D Type ensures that the insert is screwed tightly up to the timber surface, while the Type E can be fully embedded within the pre-drilled hole.

Jet Press also stocks a variety of specialist parts which may be more suitable for an application. For instance, end-capped Type I inserts offer a neat finish where the head is visible. Large, flanged inserts spread load across a larger surface area on heavy-duty assemblies. Expanding brass Type X inserts grip tighter as the bolt is screwed in, and serrated Type P ensure a high pull-out resistance.

01623 551800

[email protected]

www.jetpress.com