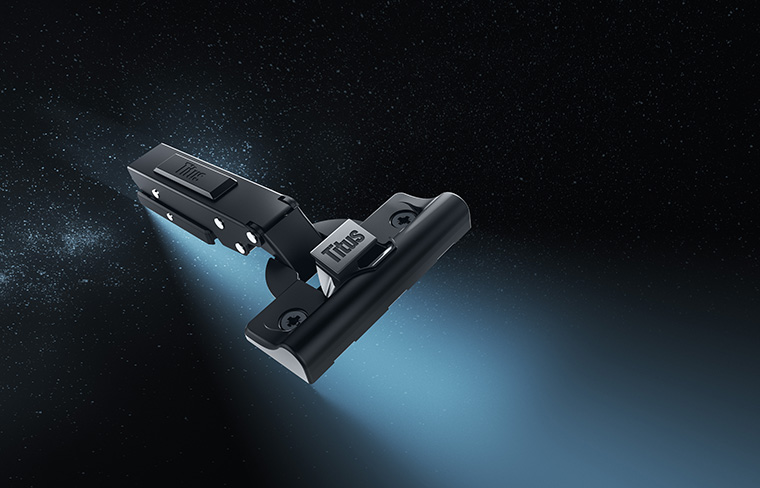

In recent years, there has been a growing trend towards interior design furniture elements in darker and matte colour tones. This has led to a demand for cabinet hardware that blends in seamlessly with the sleek matte designs. Thanks to its new TeraBlack, Titus is able to deliver an extremely attractive black matte hardware finish that not only enhances the appeal of cabinets, but also lasts a lifetime.

TeraBlack products have a light absorbing micro-structure that provides a unique black, non-reflective, matte finish, and a smooth, even surface with a velvety feel. These new products provide increased corrosion resistance and durability throughout the lifecycle of the product.

The flagship product in the TeraBlack finish range is the innovative, award-winning T-type hinge with integrated damping. Its key feature is the simplicity and tolerance during installation. T-type is designed to provide ConfidentClose – the consumer-preferred way of the soft closing of doors.

Soft closing assures above-average consistency of performance with no bounce effect, and reliable closing at all closing speeds. Its three-way snap-on intuitive hinge-to-plate mounting (top, front and back) makes installation a breeze, especially on tall doors, says Titus, as it significantly reduces the time and effort it takes to assemble a kitchen.

Cutting cabinet assembly time in half

Titus offers one of the largest and most comprehensive ranges of quick-assembly solutions for series furniture manufacturers. The 50% reduction in assembly time is possible by pre-inserting the Quickfit dowels and cams into the panel during factory production prior to shipping the cabinet. Consumers get all the connectors already fitted in the right place – all they have to do is to put two panels together and tighten the joint.

Titus Quickfit dowels with Quickfit TL5 ‘Full Metal Jacket’ are one of the fastest fittings on the market, developed to make cabinet assembly easy and without the need for tools. Thanks to its steel sleeve, the Quickfit TL5 dowel is the only dowel on the market that reliably engages in a 5mm dowel hole, enabling the use of the tool-less Quickfit dowel insertion technology across a wide range of applications where 5mm drilling is the standard.

Furthermore, Quickfit dowels also protect cabinet quality – as there is no need to use hammers and screwdrivers to insert them, there will be no damage to the carcass during insertion.

Titus enriches its portfolio

Titus has been delivering damping solutions for sliding doors for years. After acquiring Simon Kinetics from Germany, Titus formed its own Kinetics division, and now combines Kinetics’ expertise in sliding door soft closing with Titus’ expertise in hydraulic damping.

Slidix Centro is one of the most recent innovations from Titus’ Kinetics Division. It is ideal for controlling the motion and centring of middle doors in the composition of three or more sliding doors.

PushPlus is another innovative solution from Titus for pocket doors. Typically, a pocket sliding door in a fully open position stops slightly before the wall hole, protruding and obstructing the area available for moving. The PushPlus system allows the door to be used without a handle, and to retreat entirely into the wall. To close, it can be activated with a push.

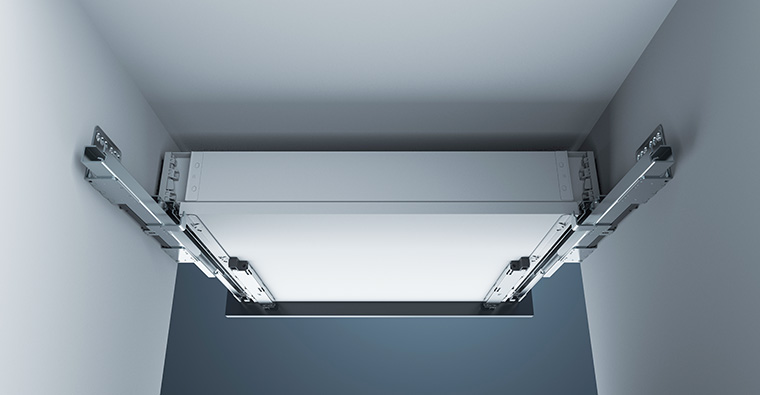

Effortless touch-opening system on drawers

Tekform Slimline thin wall drawers have now been upgraded with Tacto touch opening for the effortless opening of drawers without the need for handles. Tekform Slimline Tacto has the activator integrated into the drawer runner, while all other components remain the same as for the ‘standard’ Slimline version, as do the drilling and fixing positions.

The Tacto mechanism follows the ‘One-for-All’ principle, meaning that one item provides a push-open feature for all metal and glass drawers from 400mm in length and up to 40kg in weight. Tekform Slimline Tacto is fast and easy to mount, as it fits the industry-standard drilling patterns and allows furniture producers to streamline their operations.

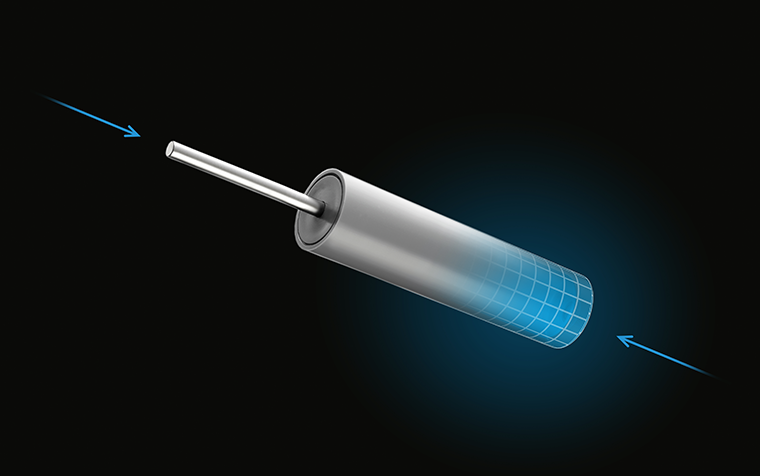

The future of damping solutions

Titus Damper is a proprietary multi-purpose hydraulic damping technology for a wide range of applications in furniture, consumer appliances, interior doors, bathroom equipment, automotive and many more areas.

The temperature spectrum for these dampers is being further extended to provide operational efficiency in cooler temperatures, as well as hotter ones. This is an especially useful feature in ovens, coolers, refrigerators, automotive and aircraft industry applications.

Titus’ newly launched damper S-Series Evolut has been developed for effective deceleration of objects up to 900N in environment of temperatures up to 150°C. It maintains consistent damping in all conditions, even when the temperature in the application reaches the upper limit.

The possibilities for application extend over a wide range of industries, from consumer appliances, such as ovens with heavy doors, to heavy lids in waste bins, plus glass doors and interior doors in residential and commercial environments.