According to Biesse, they are the first in the market to launch a set-up system that can execute configuration of an entire pod and rail bed in a maximum of three seconds. By delivering a sea change in set-up efficiency, the XPS has the potential to transform the productivity of joinery and furniture manufacturing workflows.

For the majority of furniture and joinery manufacturers, small batches and JIT production have become the norm. This can mean that operators are spending more time setting up machines than running them. In order to maximise productivity, it has become more important than ever for manufacturers to minimise the time it takes for their CNC machines to change from one job to the next. This is particularly true on a pod and rail machines, as setting up the pods/clamps and support rails correctly can be very time-consuming.

Fortunately, on today’s CNCs and pod and rail machines, varying degrees of assistance and automation can be applied to table set-up, accelerating the repositioning of the pods and rails and minimising the possibility of setting errors.

Automating set-up

Biesse offers four systems for reducing set-up time on its Rover CNC pod and railmachines. These range from a simple tool called Set-up Assistant, which assists with manual positioning, to its highly sophisticated XPS system, which completely automates the positioning of pods and rails to achieve unprecedented set-up speeds.

Set-up assistant

Biesse’s most basic tool for facilitating table set-up, Set-up Assistant, acts as a guide for the operator when manually setting up the table. It tells the user where to position the pods and uses a traffic light system to indicate whether or not the pods are in the correct position – only when all pods are showing green lights will the machine begin its programme.

This tool increases table set-up time by on average 20% versus a completely manual process, but more importantly, it eliminates the risk of the CNC colliding with out-of-position pods and causing costly damage.

Electronic Positioning System

The EPS (Electronic Positioning System) is Biesse’s entry level automated set-up system. This will automatically configure the entire working area without operator intervention in as little as 30 seconds. The limitation of the EPS versus more sophisticated systems is that it can’t sense when a pod has been moved manually.

The Electronic Positioning System automatically configures the entire working area without operator intervention in as little as 30 seconds

When the machine is first turned on it performs a homing cycle to find the zero reference point. If an operator then moves a pod manually, the pods and rails lose their reference and the machine has to repeat this homing cycle.

Feedback Positioning System

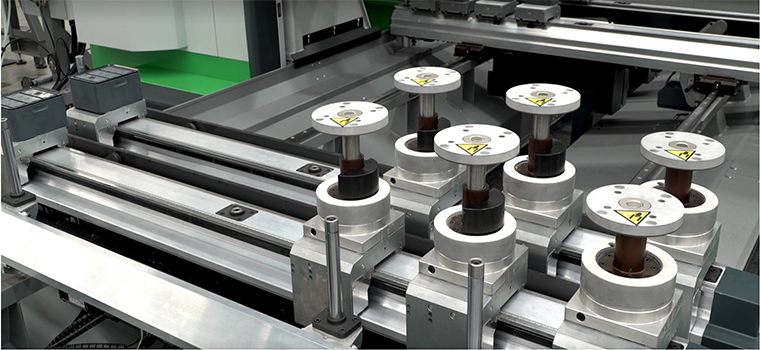

Until the launch of the XPS, the FPS was the industry’s leading system for automated table configuration. Thanks to the use of magnetic sensors, the machine knows the exact position of each pod at any given time.

These sensors work by providing position feedback to the machine’s control system. This means that if the operator moves a pod or rail, the machine does not have to go through a homing cycle, making it a quicker positioning system than the EPS. The entire working area can be configured in just 20 seconds with FPS.

On the FPS, the pods are moved via guides - with one set of guides per rail. This means the pods are moved into position one at a time rather than simultaneously. The rails themselves have individual motors, allowing them to move into place simultaneously.

Extreme Positioning System

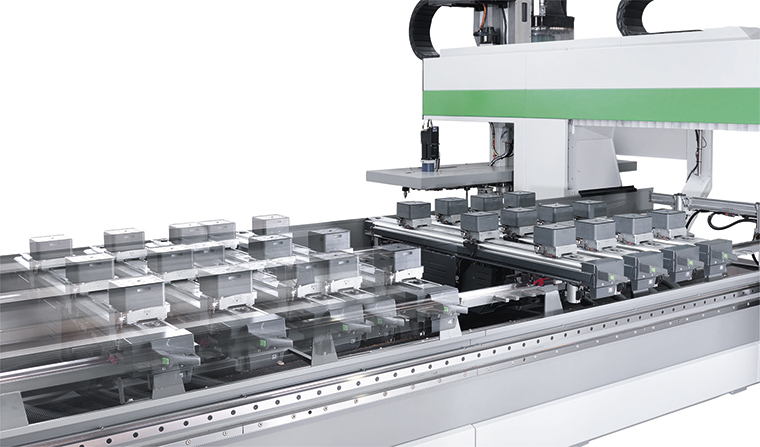

The ultimate automated table configuration tool, the XPS (Extreme Positioning System), takes just three seconds to set up an entire table. The key to this breakthrough is that every pod has its own motor with rack and pinion.

This enables the pods to move simultaneously and independently, as they are not sharing a drive with the other pods on the same rail as on the FPS and EPS systems. With XPS, the carriage moves at speeds of up to 23m/min on the x-axis and 32m/min on the y-axis and pod placement accuracy is within +/-0.15mm.

Self-learning functionality

Both FPS and XPS have an in-built ‘self learning’ function. This comes into play when an operator is not sure what size a panel is until it is placed on the table and cannot, therefore, call up an existing programme. It is also useful when machining an intricate part that requires a jig.

In these scenarios, the operator can position the pods manually and those coordinates will then be saved within the machine’s software. So, the next time that the same workpiece or task is required, the saved configuration can be recalled and automatically position the pods accordingly.