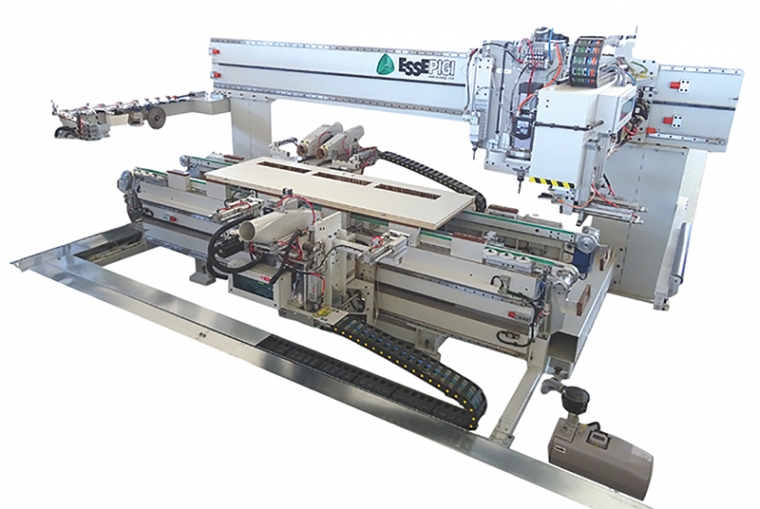

Making its UK debut at the W Exhibition is the Essepigi Doormatic Evolution high speed through-feed CNC working centre for door production. Essepigi is a specialist in the area of door production and is able to supply stand alone machines or complete lines with infeed and outfeed handling. Several machines have already been installed in the UK this year by Essepigi’s exclusive UK distributor, JJ Smith.

“The Doormatic is the ideal solution if the requirement is for volume production,” says Paul Parker from JJ Smith, “but with the ability to quickly and easily change from one door size to another.

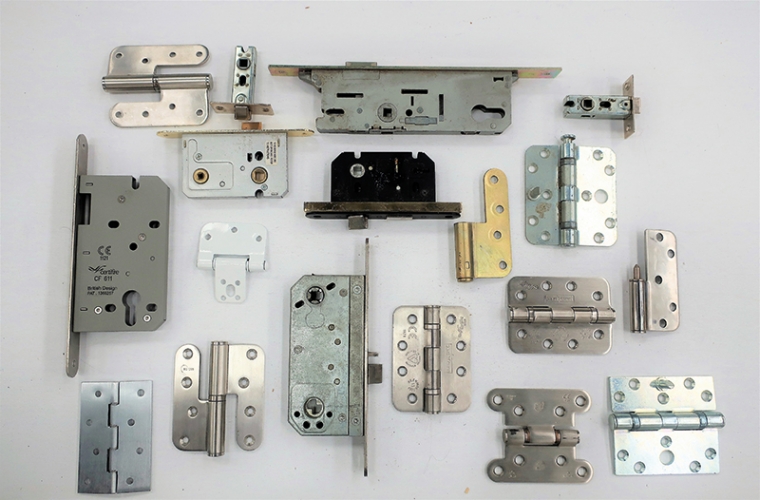

“This is a double sided machine, meaning both sides of the door can machined at the same time, thus maximising production output. Typically, on one side, there will be a horizontal router head for hinge recessing and a drilling unit for spot drilling of the hinge screw holes, both of which are CNC controlled. On the opposite side there is a horizontal router head for lock slot/face plate recess along with a vertical router for handle hole and key slot, again all CNC controlled.

“Standard features include automatic width setting through the program and the ability to select left hand or right hand configuration of the door. Options include thickness and width taster for accurate machining control, offline programming and an end milling head to produce the drop seal groove.

“Programming is quick and simple thanks to the dedicated Essepigi Door Software incorporating electronic macro templates for hinge/lock hardware. Throughput on the Doormatic, machining for three hinges with drilling, lock case slot and faceplate recess on a typical internal flush door would be approximately one door per minute,” explains Paul.

“When there is a requirement to also size a door and/or produce an opening for a vision panel or letterbox, then the Doormatic Bridge Evolution is the ideal solution.

“The main features of the Evolution Bridge, additional to all above machining capabilities are a vacuum hold down system and an automatic linear tool changer for the vertical three axis router head. The floating router head option gives the facility for precise engraving of designs on to the door face. In terms of production output for a fully machined door, including sizing/drop seal groove / vision panel aperture/lock/hinges an estimated time would be around four to five minutes.

“This compares to around 12 minutes if the door is being machined on a conventional flat bed CNC router. Options on both models include barcode or QR code reading for the setting up all the required operations and also automatic hinge inserting.These machines are suitable for processing internal flush or panelled doors, fire doors or composite doors,” concludes Paul.

Visitors to the W Exhibition can see the Essepigi Doormatic Evolution on stand JJ Smith’s stand G510.