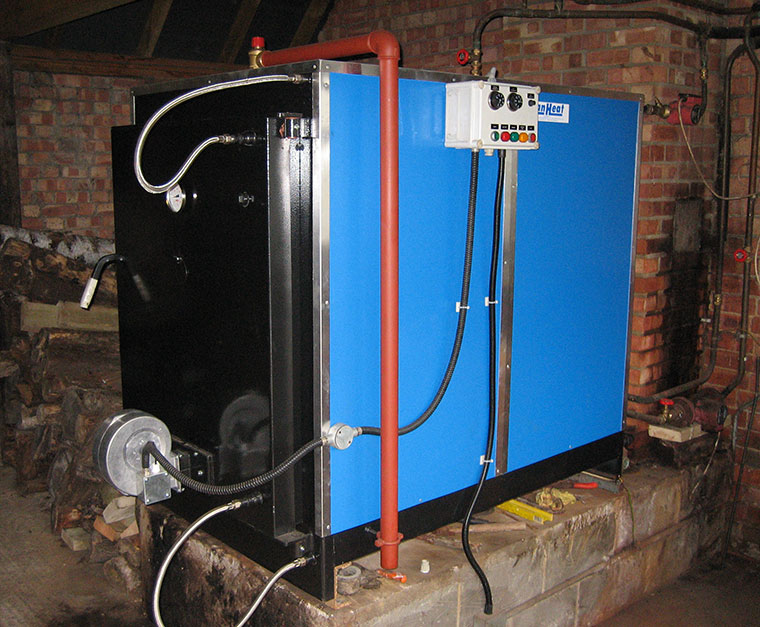

300 kW warm air heater

.

“Well at the least, COP26 has grabbed the headlines in early November,” comments Chris Franklin, MD of Ranheat Engineering. “Greta Thunberg is now a household name. This young Swede (born in 2003) is now challenging world leaders to take immediate action for climate change.

“Ranheat Engineering, the UK’s leading and most long-established manufacturer of industrial wood fired boilers and heaters, also has its roots in Scandinavia. Ranheat was originally founded in the town of Randers in Denmark over 50 years ago.

“So why did Danish technology lead the way? It wasn’t climate change that drove the development of biomass burning boilers 50 years ago, it was lack of alternatives. The UK was an island of coal in a sea of oil and gas. Denmark had no coal, no oil and no gas supply, but what Denmark and the rest of Scandinavia did have was Biomass. Originally in the form of straw and wood.

“I worked for Ranheat Energy A/S in Denmark over 30 years ago. Originally the products were made in Denmark, but production in the UK moved to Northamptonshire in 1990, so for over 30 years Ranheat’s products have been made in the UK. The growth of Biomass burning equipment in the UK was driven by escalating world oil prices not by climate change, at that time. How different to now.

An early on-farm Ranheat Boiler

“COP 26 has not put the use of Biomass in a good light, with many references to Drax power station using wood that has travelled thousands of miles from Sweden or Canada or other far-away places, often by ship and lorry, to get it to site.

“So how does this affect the UKs Woodworking Industry? By making more products from wood we help the environment in many ways.

“Firstly, we are using a renewable resource to manufacture with. Take the case of wooden windows against UPVC. At the end of life, the wooden window can be turned into energy, not the case with plastics often non-recyclable. Furthermore, the waste material from the manufacturing process can be used to heat the production unit. This means that all the timber is either turned into product or used for energy.

“So, world leaders should be encouraging wood as a chosen material over other non-recyclable materials or materials that have a high carbon footprint to manufacture. Bricks and concrete, for example.

“Holland recently announced that 20% of new homes to be built in Amsterdam are to be made from wood. It is claimed that this will reduce the cities carbon emissions by 220,000 tonnes per year.

“All companies in the UK wood manufacturing industry should be promoting wood as THE material to use for construction of buildings, homes, furniture, and fittings. This will help create a sustainable industry that can be seen to be doing its part to reduce the effects of global warming.

“Over the last 30 years, Ranheat has developed industrial wood-fired boilers and heaters that can burn all wood and wood-based products efficiently, including natural timber, chipboard, MFC, MDF, plywood in either the form of extracted sawdust and shavings or granulate from a wood-chipper.

“As well as utilising the by-product effectively, it also cuts down on transport of having to take away waste from a manufacturing site for disposal so cutting out emissions from lorries in doing so.

“Ceramic flue gas filtration also removes harmful particulate and wood contains no sulphur. By correct design of the combustion system NOx and CO are also minimised.

“So, the use of Biomass correctly will have a good effect on climate change. The UK woodworking industry can help Greta meet her targets – every little helps!”

01604 750005

www.ranheat.com